Welding rod is also known as electrods. It is a piece of flux coated metal wire. It is made of metal alloys like carbon steel, stainless steel and other alloys. These welding rods are used in many welding processes such as Shielded metal arc welding (SMAW), Gas metal arc welding (GMAW), and Gas tungsten arc welding (GTAW).

There are different types of welding rods are such as 308 welding rod, 309 welding rod, 6013 welding rod, 6011 welding rod, 7018 welding rod, fill freeze welding rod, fast freeze welding rod, fast fill welding rod and so on. Today we are going to know about the major Between a 308L and 309L Welding Rods.

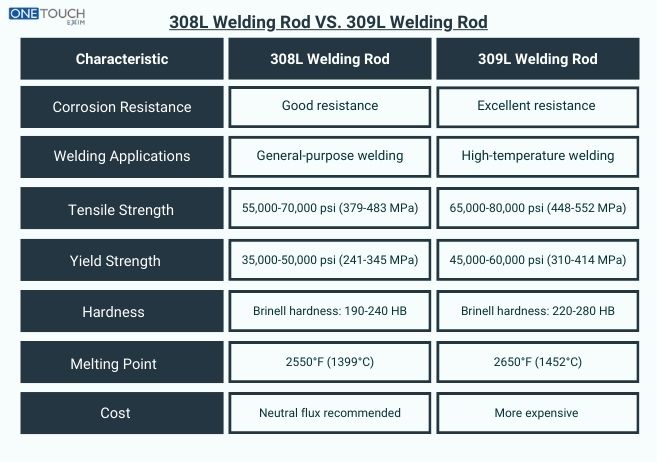

Difference Between 308L and 309L Welding Rods

Here we discuss the difference between 308L welding rod and 309L welding rod.

What is a 308L Welding Rod?

A 308L welding rod is a stainless steel low carbon electrod. It contain the element such as molybdenum, nickel, chromium, small amount of silicon, manganese, and titanium are also present in it. 308L Welding Rod has a low -carbon content with an iron coating. It is an austenitic stainless steel electrod. This rod is good for welding stainless steel. 308L Welding Rod is very versatile.

What is a 309L Welding Rod?

A 309L welding rod is a stainless steel low carbon electrod. It contains the elements such as nickel, molybdenum and chromium. 309L Welding Rod is good for welding stainless steel. It has a lower carbon content and higher silicon content. The thickness of this rod is between 2.0 mm and 4,0 mm. This welding rod is use to weld the, low carbon grades of stainless and for weld the low alloy steel.

Properties of 308L and 309L Welding Rods

309L Welding Rod

A 308 L welding rod contain very low amount of carbon, so it is good for control the fire during welding and protect the place from fire because it produce the very low spatter level. The weldability of this welding rod is very god , so it weld the any metals very easily in any positions, the corrosion resistance of this welding rod is very excellent because of low carbon composition, it can also be used in place of shielding gas.

309L Welding Rod

A 309L welding rod have many good properties such as, it is very good in corrosion resistance because of very few amount of carbon content, It is very good heat resistance because it have a good amount of nickel and chromium, it have a high ductility and strength so it is reduce the mechanical stress and weld the metal without any fracturing, due to medium penetration, it is stable for welding the thin materials with their integrity, it is versatile welding rod so it joint the metals by welding very easily.

Uses of 308L and 309L Welding Rods

308L Welding Rod

From its strength, durability, and ductility we use 308l welding rod for welding the pipelines, for making the structure fabrications, 16 ptwelding the thin-gauge material, because of its good corrosion resistance it is use in making the building, bridges, and for welding stainless steel such as 302, 304L and 308. Also it is us16 pte for making main types of stainless steel available in market likes ASTM A 743, CF-8 and 744 grad.

309L Welding Rod

Due to its good strength, weldability, corrosion resistance, it is used in many fields such16 pt as in food processing equipments such as food,processor and grinder, oven and cooker, slicer and cutter, vacuum sealer and packer, refrigerator and freezer, mixer and blander, used in aerospace industry for joining and repairing the aircraft engine because of its strength and high temperature resistance and also used in petrochemical industry for searching the harsh and corrosive chemical by welding the stainless steel pipe and equipments.

Cost of 308L and 309L Welding Rods

308L Welding Rod

A 308L is affordable in price comparatively 309L welding rod because it is use in general purpose but 309L welding rod used in airspace industry, petrochemical industry and so on.

309L Welding Rod

A 309L welding rod is expensive comparatively A308L welding rod because it is used in big industry such as aerospace industry, petrochemical industry but A308L welding rod use in general purpose.

Conclusion

Here in this blog we have tried to put all the collected information about 308L and 309L welding rods such as properties, uses, cost and so on. the 308L and 309L welding rods are both high-quality options for welding stainless steel, but they differ in their composition and performance. The 308L rod is a more general-purpose option, offering a good balance of strength, corrosion resistance, and weldability, making it suitable for a wide range of applications. In contrast, the 309L rod is a more specialized option, offering improved high-temperature resistance and corrosion resistance, making it particularly well-suited for applications in harsh environments or where high temperatures are present. Ultimately, the choice between the two rods will depend on the specific requirements of the project, with the 308L rod being a good all-around option and the 309L rod being a better choice for applications that require exceptional high-temperature resistance.