Another name for welding rods is electrodes. They play a very important role in the process of welding. They work as a filler in binding two base metals together. They help in passing heat and electricity to the metal we are binding. There are two types of welding rods one is consumable electrodes and the other is non-consumable electrodes.

Consumable rods melt to bond the base metals, while non-consumable on the other hand do not melt but only generate arcs. Non-consumable rods are also called tungsten electrodes. There are various types of electrodes and they all have different purposes. In this blog, we learn about a particular type of welding rod that is the 6011 welding rod and its uses.

WHAT IS 6011 WELDING ROD?

6011 rods are used for general purpose welding. They are classified as a fast freezing electrode. They have a coating of high potassium cellulose. They work on both AC, DC and DC+ welding currents. Its tensile strength is 60,000 PSI (pound per square inch).

6011 electrodes are easy to use and thus makes them the best choice for beginners. These rods are used for fabrication and all-purpose repairing. These rods can be used on dirty and oily surfaces for deep penetration and so are widely used for repairing cars, engines, and other greasy, dirty surfaces.

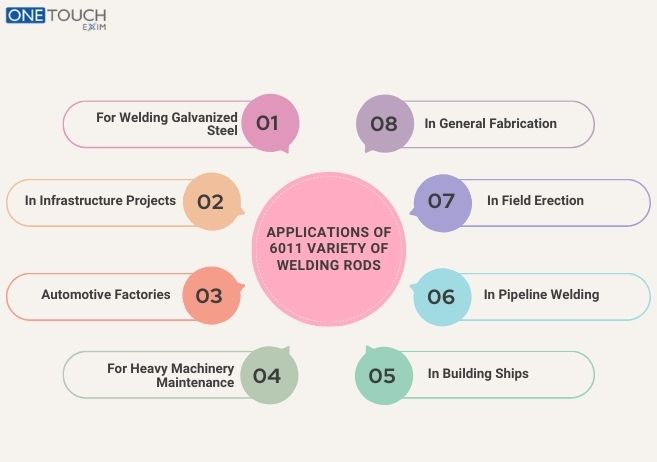

APPLICATIONS OF 6011 VARIETY OF WELDING RODS

6011 electrodes are used for multi-purposes. Some of them are listed below:

1. For Welding Galvanized Steel

6011 is the best choice for welding on galvanized steel because 6011 has the coating of cellulose. It has the potential to protect the weld puddle from zinc coating and oxidation.

2. In Infrastructure Projects

6011 can be used in welding infrastructure projects like buildings, pipelines, bridges etc., due to their deep penetration capabilities. Though they might not be the very best choice because of their usage limitations in root passes.

3. Automotive Factories

6011 electrodes have fast-freezing properties, they are versatile and have multi-current capability, which makes it an ideal choice for aerospace and automotive industries.

4. For Heavy Machinery Maintenance

Due to its various properties like low spatter, deep penetration, all-position welding, multi-current capability etc., 6011 electrode is a preferred electrode for maintenance of heavy machines. For example equipment used for mining, agricultural, industrial and other heavy machines.

5. In Building Ships

6011 is an ideal choice for welding in shipbuilding because its properties like deep penetration and allow welding through dirt and grease.

6. In Pipeline Welding

It is also used in pipeline welding because it provides adverse welding and it can tolerate corrosive surroundings. It also provides deep penetration and all-position welding making it a good electrode for pipeline welding.

7. In Field Erection

6001 electrodes have high arc ability, require low current, can weld through dirt and grease and allow deep penetration. These qualities of 6001 electrodes make them an ideal choice for field welding.

8. In General Fabrication

These electrodes are used for general fabrication because of their versatility, low silicon deposit, deep penetration and fast freezing property.

SAFETY MEASURES

- 6011 electrodes should be used with care to avoid hazardous situations. They are fragile and can break on excessive twisting or bending.

- These electrodes should not be placed anywhere near fire. They should be stored in a cool and dry place.

- The process of welding can generate toxins. So, make sure that the place where you are welding is well ventilated, to reduce the chances of toxins inhalation.

- Make sure you wear PPE (personal protective equipment) properly while welding to avoid any accident.

- Ensure that there are no combustible materials near the place you are welding.

- Always keep a fire-extinguisher near you while welding.

CONCLUSION

The 6011 variety of electrodes have various qualities and are used in various ways. They might not be as reliable as other electrodes, but are the best choice for beginners.