A drill bit is a special tool that uses rotation to cut circular holes in different materials and products. It comes in various shapes, sizes, dimensions, and designs. Usually, a drill bit is attached to a drill to create holes in the workpiece. Hardened steel is a type of steel that undergoes a heat treatment process to increase its strength and durability by heating it to a high temperature and then rapidly cooling it. On the other hand, stainless steel is a type of steel that is difficult to drill due to its unique property of containing at least 10.5% chromium. Now, let’s understand the different types of drill bits used for stainless steel.

Best drill bits for stainless steel

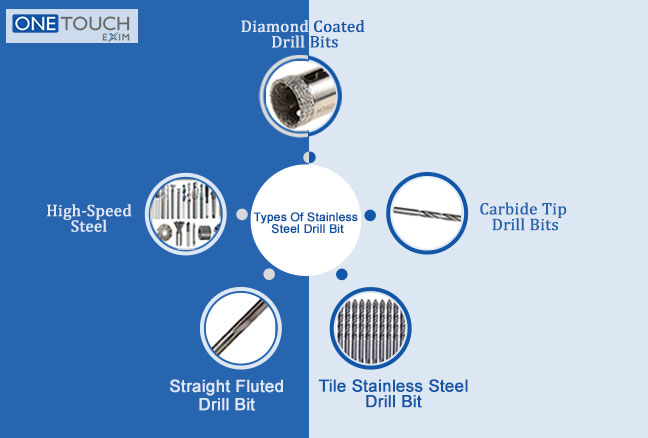

Due to its high toughness and strength, it is difficult to drill steel plates. But with the right drill bit you can perform the work easily. There are 5 types of drill bits for stainless steel-

Cobalt Drill Bits:- Manufacturers make these drill bits from a mixture of high-speed steel and 5% to 8% cobalt. Cobalt drill bits for stainless steel are much stronger than high-speed ss drill bits and can easily bore through tough materials like hardened and stainless steel plates. They can withstand high temperatures, are exceptionally long-lasting, and have high impact resistance and extreme strength.

Carbide Tip Drill Bits:- These drill bits are made from tungsten carbide, one of the toughest and most durable substances. They are used for precise drilling on materials like steel, cast iron, and aluminum. Carbide drills are frequently chosen over conventional high-speed drill bits because of their greater heat and resistance and ability to keep their sharpness longer. They can cut more quickly and accurately.

High-Speed Steel (HSS) Drill Bits:- These drill bits are appropriate for drilling through steel plates that are ¼ inch thick or less since they are made of a robust steel composition. They come in various sizes and shapes, and they are perfect for general-purpose drilling tasks. These drill bits are used for drilling wood, light metals, fiberglass, and PVC.

Titanium Drill Bits:- Drill bits made of titanium are stronger and more heat-resistant than drill bits made of conventional HSS because of the titanium nitride coating on the drill bit. They work well for drilling through up to ½-inch-thick steel plates. Titanium drill bits are mostly used for drilling iron, steel, aluminum, magnesium, and wood.

Diamond-Coated Drill Bits:- Drill bits with a diamond coating are very strong and durable due to the layer of tiny diamond particles. They can be used to drill through steel plates that are ¼ inch thick or less, but they are typically used to drill through very hard materials like ceramic or glass. These bits get their extra cutting power from the little pieces of diamond powder embedded in them. They are available in small sizes, such as 0.75 mm to 3mm.

What Is The Best Way To Drill Stainless Steel

The best way to drill stainless steel involves several key steps, including selecting the appropriate drill bit, using lubrication, setting a lower drill speed level, starting with a pilot hole, and using a cutting fluid formulated for stainless steel.

By following these steps, you can ensure a successful and precise drilling process while minimizing the risk of damaging the drill bit or the workpiece.

Choose the right drill bit:- When it comes to drilling through stainless steel, selecting the right drill bit is the most important task. Ordinary drill bits may struggle to efficiently cut through the material, resulting in a dull or broken bit.

Use Lubrication:- For optimal drilling performance, it’s essential to use lubrication while drilling through stainless steel. A suitable lubricant reduces heat and friction, which can cause damage to the drill bit and the workpiece.

Use Low Speed:- To avoid damaging the drill bit and the workpiece, it’s important to use a slower drilling speed when working with stainless steel compared to softer materials. Adjusting the drill to a lower speed.

Apply Steady Pressure:- It is important to apply steady pressure on the drill to avoid damaging or breaking the drill bit, while also avoiding too much pressure that may cause it to slip or break.

Start with a pilot hole:- Starting with a pilot hole is a recommended practice when drilling through stainless steel. The pilot hole serves as a guide for the drill bits, resulting in more precise drilling and minimizing the risk of the bit wandering off course.

Avoid Overheating:- Overheating is a common issue when drilling stainless steel, which can lead to work hardening and make the drilling process more difficult.

Use Clamps or Fixtures:- Using clamps or fixtures is necessary to secure the workpiece firmly to prevent it from moving during the drilling process while drilling stainless steel.

Choose Carbide Drills:– Carbide drills are an excellent choice for drilling stainless steel. Offering precision, extended tool life, and efficient chip evacuation due to their extreme hardness and heat resistance.

Use Cutting Fluid:- Using a cutting fluid specifically formulated for stainless steel can be highly beneficial in the drilling process. The fluid helps to reduce friction and dissipate heat.

Practice & Patience:- Drilling stainless steel can be challenging, especially for beginners. But, with practice and patience, you can improve your skills and achieve better results.

In conclusion

Drill bits are a crucial part of manufacturing, especially in products that need assembly. They come from different materials and have different shapes, sizes, and other factors leading to the different types of drilling bits used for stainless steel, each one of them having unique applications that are used for specified tasks. After the types of drilling bits, it is clear that choosing the right drill bit for steel is crucial for achieving accurate results which has been discussed in 10 tips for drilling stainless steel.