| Alloy Basis | Cr – 24 to 30%, C – 4.0 to 5.5%, Si – 0.45 to 1.20%, Mn – 0.4 to 0.65% |

| Hardness | 74 – 76 HRC |

| Hardness Resistance at High Temperature | Up to 250 to 300°C |

| Cutting | Plasma Cutting & Water Jet Cutting |

| Cold Forming Minimum Radius | Minimum Radius: 150 mm (For 6+4) Using Hydraulic Press to bend |

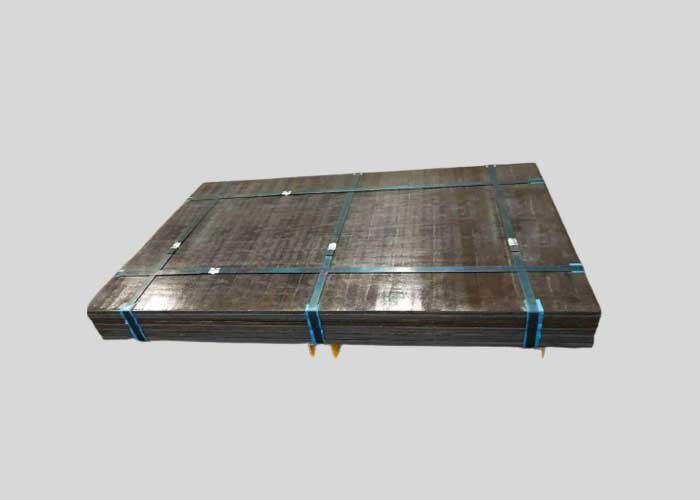

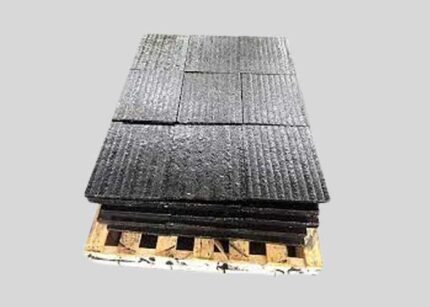

OTEP 75CH

OTEP 75CH is a high-strength steel plate with exceptional resistance to abrasion and wear. It is made of hard and durable alloy material, guaranteeing an extended lifetime for industrial applications. The hardness for this type of Wear Plate reaches up to 75, making them suitable in cases where impacts are heavy and equipment must be safeguarded from such abrasive forces. We One Touch Exim are the manufacturer & supplier of OTEP 75CH Wear Plates in India, and these are available to buy from our online stocks.

Category: Chromium Carbide Overlay Wear Plates

Description