When we talk about what is meant by Butt Welding. Then we are talking about the most simplest form of welding, where you join two metal pieces together end to end without overlapping them. In this process, the edges to be joined are essentially matched up in the same plane and heat is incremented over the plastic surface until it melts, Occasionally fillers are used too. When the temperature goes back down the metals have already fused solid, essentially becoming one piece end to end. It is used in pipelines, construction and manufacturing because of its efficiency and strength. Methods like cleaning edges lead to a good weld. Various processes can be used to perform butt welds, such as arc welding or resistance welding depending on the material and application requirements.

Why is Butt welding easy ?

Butt Welding is easy because it does not require intricate welds over each other or intricate angles, Butt welding is said to be one of the easier types of welding. The edges are flush in the same plane and the setup is easy and a method that most welders have seen or done themselves. Less joint preparation is needed- just cleaning before applying heat and filler material. The general welding standards like MIG, TIG or arc welding can be utilized, which gives adaptability. As butt welds are straight and relatively constant, although they are simple to control and inspect.

Types of Butt Joint

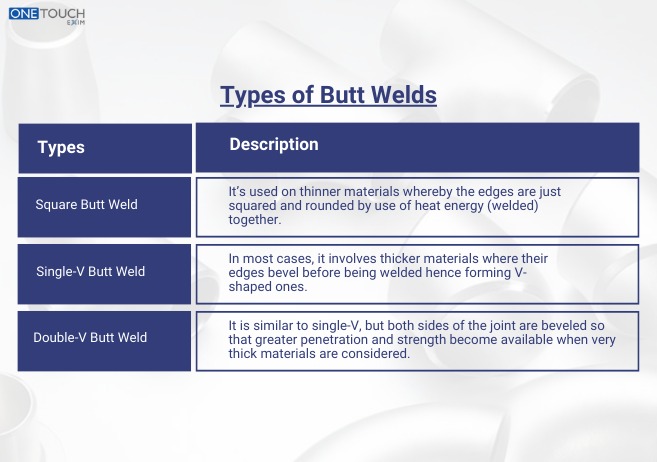

A butt joint is the most basic form of welding joint, it is where two pieces of metal are placed edge to edge in the same plane. Common types include:

Square Butt Joint :

Just like Flush Square, except both edges are straight and square instead of being angled for thin materials.

Single-V Butt Joint :

Beveled edges on one side, used for thicker metal.

Double-V Butt Joint :

Beveled on both sides; the stronger weld you can make for heavy-duty applications.

Single-V Butt Joint :

Edges include a groove to reduce filler and increase mass.

U Double :

Both sides have U grooves, this joint has high strength especially for larger thickness.

Butt Welding Symbols

Butt Welding symbols are used in engineering drawing to indicate the kind of size and all other specifics with butt welds. In general these symbols have a reference line with an arrow showing where the joint is located and there are several additional markings that represent type of weld, root penetration depth and angle or pitch as well as finishing requirements. Added symbols could specify well all around, field welds or contouring data. Symbols adhere to ISO or AWS standards for optimum communication between designers and welders. These symbols need to be read properly in order to provide the exact high quality weld required for application relating to construction, piping and manufacturing.

Benefits of Butt Welding

There are too many benefits of Butt Wielding; it is widely used in metal fabrication. It makes powerful smooth bonds with larger structural strength great for fill bearing software. It is an efficient process for quick assembly of pipes, plates and structure working with a minimum material wastage. Butt Welding creates a load that distributes evenly along the joint, minimizing any amount of stress points seen with overlap joints. The result is a clean smooth weld, with minimal post weld machining. Used for automation, improves productivity in construction, automotive, pipelines etc. On top of that, it can operate with multiple metals and more welding techniques bringing a broad capability range in a variety of engineering projects.

How to Maintain Quality in Butt Welding

To maintain quality in Butt welds, it requires proper preparation technique and inspection. Proper alignment and joint edge preparation can help to reduce defects – Here are some common tips to get good welds – use the right welding method and parameters. The ideal condition is weld as per standards recommended in table – I filled Type M, S ot T. Keep heat consistent to avoid cracking or warping. Highly trained welders are ideal following standard procedures with the correct shield gas or flux to prevent contamination. After welding, examine for any signs of defects such as cracks, porosity, incomplete fusion by visual inspection or X-rays or ultrasonic testing. This equipment calibration and AWS/ISO standard compliance are also important to maintain a high structural and piping weld quality.

Pros. with cons. Of Butt Welds

Butt welding produces superior quality welds and is often used for pipeline and structural application because it produces joints with great strength with minimal stress concentration as compared to other methods. The good news is, it is fast, material reducing, automation friendly, and guarantees uniform quality. This process is applicable to all types of metals and ensures high code accuracy with least machining. Butt Welding however needs excellent edge preparation and technical ability to prevent defects such as cracks or inadequate fusion. It can also lead to warping because of high temperature and is not a very good fit for dissimilar metal joining.

Conclusion

A flexible and productive welding technique, Butt welding is applied across industrial sectors ranging construction to automotive and pipeline due to high tensile-strength, gapless joints capable of material conservation. It comes with uniform stress distribution, smooth finishes and is automation compatible, but it requires precise preparation, skilled execution and inspection to avoid defects. The process of converting from unprocessed materials to visors requires correct edge alignment, heat regulation and quality checks. Butt Welding is still a reliable and cost effective way to create long lasting metal related products, when performed under standard guidelines, despite facing challenges such as heat distortion and dissimilar metal limitations.