Welding is considered the most important factor in applications like the manufacturing and construction industries. The welding is the process of joining two or more metals together permanently. Welding symbols are used to communicate important information about the weld joint to welders to ensure precision and consistency. They enable engineers to communicate their design requirements effectively, allowing welders to understand the specific weld characteristics needed.

Here in this blog, we will talk deeply about the basics of welding symbols and their meanings. We are providing you with a comprehensive guide for both beginners and experienced welders.

What Are Welding Symbols?

Welding symbols are the graphical representations that are used to communicate the specifications of a weld joint in the form of technical drawings. These symbol represents the information such as the type of weld, the process of welding that is to be used, the dimension of the welding, and any other details that are required to produce a high-quality welds. Welding symbols also aid in quality control and inspection processes, as they provide a clear reference for evaluating the completed welds against the specified standards. While using the standardized welding symbols the engineers, designers, and welders can ensure precision and clarity in the process of welding.

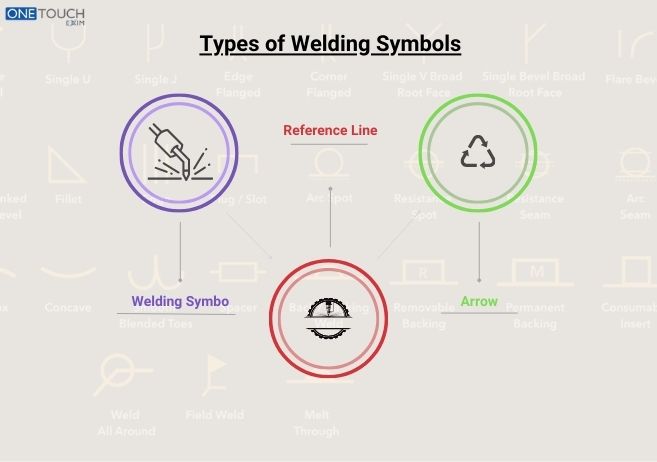

Types of Welding Symbols

There are various types of welding symbols, each of these types representing the different aspects of the weld joint. Some of the most common welding symbols include:

Welding Symbol:

The welding symbol is typically a triangle that symbolizes the location of the weld on the drawing. The arrow points to the joint to be welded. The design intent and quality expectations can be made clear for a weld through the use of welding symbols.

Reference Line:

The horizontal line attached to the welding symbol is known as the reference line. It indicates the side of the joint that needs to be welded. It helps to ensure accuracy and consistency in the welding drawing.

Arrow:

The arrow on the welding symbol points to the area to be welded and indicates the direction of the weld. The arrow in addition helps in identifying the orientation of the weld so that it can be correctly done as per the design specifications.

Tail:

In the welding symbols, the tail is the most important and key component that provides important information about the weld. The tail of the welding symbol contains additional information such as the welding process, size, and other relevant details.

Meanings of Welding Symbols

Understanding the meanings of welding symbols is crucial for interpreting technical drawings accurately. Here are some common welding symbols and their meanings:

Fillet Weld:

The fillet welds are used to join two materials at the right angles which are represented by a triangle on the one side of the joint. It is commonly used in construction, manufacturing, and other industries where strong and durable welds are required.

Groove Weld:

The details about the weld size, depth, and other specifications are indicated by specific symbols with details in Groove Welds. It provides a strong and durable bond between the metal pieces, ensuring structural integrity and preventing any potential failures.

Plug and Slot Welds:

Plug and slot welds are used to join overlapping materials and are denoted by designated symbols on the drawing. This type of weld is commonly used in automotive manufacturing, shipbuilding, and structural steel fabrication.

Backing Strip:

It is indicated by a symbol with details about the type and dimensions of the strip when a backing strip is required for welding. The backing strip helps to control the shape and penetration of the weld resulting in a clean and consistent finish.

Interpreting Welding Symbols

To interpret welding symbols correctly welders need to understand the basics of reading technical drawings and interpreting the information provided. Here are some key steps to follow when interpreting welding symbols:

Identify the Welding Symbol:

Firstly start by locating the symbols of welding on the drawing and understand the components which include the arrow, reference line, and tail. Each symbol represents a different type of weld joint and provides information about the size, shape, and location of the weld.

Determine the Type of Weld:

The most important factor is to identify the type of weld specified in the symbol whether it is a fillet weld, groove weld, plug weld, or any other type. Understanding the specific welding technique being employed will help in determining the type of weld.

Read Additional Information:

The welding process, size, and any other relevant details contained in the tail of the welding symbol are very important. Take your knowledge of this important feature of welding to the next level and ensure that engineers, designers, and welders communicate accurately.

Refer to Welding Standards:

Consult welding standards and codes to ensure compliance with industry regulations and best practices. It is important to consider the guidelines and regulations that have been established to ensure the safety, quality, and efficiency of welding processes.

Conclusion

Welding symbols play a vital role in ensuring precision and consistency in the welding process. By understanding the basics of welding symbols and their meanings, welders can interpret technical drawings accurately and produce high-quality weld joints. Whether you are a beginner or an experienced welder, mastering the art of interpreting welding symbols is essential for success in the field of welding. Incorporating these symbols into your workflow will enhance efficiency, clarity, and overall quality in your welding projects.