Nuts play a significant role in holding objects together and are a crucial component in the fastener family. Nuts ensures long life of certain products that use metals as they are strong and durable. They help in preventing malfunction and damage of the components.

Nuts are of different sizes, materials and shapes. The reason why they are important is, they ensure durability and stability of bridges, infrastructure and also used in vehicles, machinery equipments, consumer goods and so on. Nuts also provide safe and reliable connection between objects.

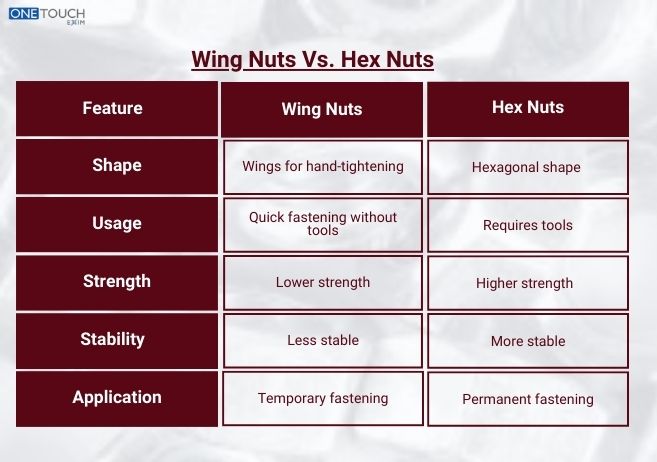

There are a wide range of nuts that are available which help fulfill different purposes. Out of these, wing nuts and hex nuts are commonly used, however they may differ in terms of elements, functionality, uses, shapes etc. In today’s blog, we will learn the primary differences between these nuts that will help you to decide which is the best for your purpose.

Difference Between Wing Nuts and Hex Nuts

Let’s dive deep into the detailed comparison between wing nuts and hex nuts.

1. Overview

Wings Nuts

Wing nuts, popularly known as ‘butterfly nuts’. They are a kind of nuts that have two huge metal “wings” on either side of their head. Wing nuts are made of metal. Some of the common materials used in them are steel, brass, metal alloys and several types of stainless steels. These materials offer strength and durability of the nuts. They do not require heat treatment.

They have a simple design that makes them suitable for a variety of applications. Wing nuts provide protection against corrosion and rust. Wing nuts are categorized into different types. Among them, type A, C and D are widely used.

Hex Nuts

Hex nuts are made onto a bolt shaft and have six sides. They have a common internal thread size and a consistent thread pitch. These can also be paired with other fasteners, however they are commonly used with hex-headed screws and bolts.

Hex nuts contain different materials such as plain steel, stainless steel, zinc, aluminum, carbon steel, hot-dipped galvanized steel, brass, nylon and others. These elements provide benefits including resistance to corrosion etc.

As they are available in a variety of shapes and sizes, these nuts are used in a wide range of commercial and industrial applications. Hex nuts also come in primary types including grade 2, grade 5, grade 8 and many more.

2. Functionality

Wings Nuts

When used in conjunction with a bolt, wing nuts are intended to hold two or more things together, just like other nuts. If you want to stop the connected objects from pulling apart, you can twist a wing nut onto the end of a bolt.

Washers are an essential component that provide hassle-free tightening to the wing nuts. These nuts provide thumb and finger a place to grab, making them more easier to tighten and loosen. Wing nuts offer a secure and reliable connection between the components.

Hex Nuts

Due to vibration or external forces, hex nuts ensure a snug fit that prevents loosening of nuts. Washers are also used in these nuts to ensure a secure fit and prevent from damage.

They also provide a reliable and secure connection between the components. Hex nuts can help prevent from over-tightening that may cause damage to surrounding materials.

Hex nuts promote a uniform bearing pressure by distributing loads across the screw or bolt and helps to reduce the stress concentrations.

3. Shape

Wing Nuts

Wing nuts are characterized by two metals, one on each side of the nut for grip and leverage. These metals are also known as ‘wings’ or tabs. They are hexagonal in shape which helps them to tighten or loosen the nuts easily.

Wing nuts have a round base with a flat bearing surface providing a comfortable grip for loosening and tightening. In addition, the configuration of the thread in wing nuts are fine, coarse, extra fine etc.

Hex Nuts

Hex nuts are hexagonal in shape as they have six sides of equal lengths with a circular internal threading. The unique shape of these nuts set them apart from other types of nuts. The circular thread is compatible with screws, bolts and others.

Hex nut’s symmetrical shape can be used in various means without compromising their functionality.

4. Installation

Wing Nuts

Wing nuts can be installed and removed easily by turning them without the use of extra equipment. However, there are certain crucial steps to consider for proper installation of wing nuts. They are as follows:

- Check if the surface is free from debris and is clean before the installation.

- Make sure that the wing nut is properly installed with its wing facing the required orientation on the bolt or stud.

- To avoid over-tightening, fasten the nut by hand and check the snug fit. Over-tightening may cause damage to the components.

- Use the wing nut installation tool for better torque and convenience. This tool centers the wing nut for a snug engagement which facilitates tightening and loosening.

- Consider the ergonomic factors like handle size and design, material etc., when selecting a wing nut during installation, to minimize the fatigue and discomfort.

Hex Nuts

Hex nuts ensure a secure and reliable joint. Here, we have listed the steps for installing hex nuts. They are as mentioned below:

- Make sure that the size and material of the hex nut matches that of the bolt or screw.

- Remove contaminants and clean the threaded area, and ensure that the area is not damaged by corrosion.

- Then, ensure proper alignment and fix the position of these nuts onto the threaded screw or bolt.

- With the use of pliers or wrench tighten the nut in a star pattern for uneven hold.

- Consult the manufacturer’s instructions for suggested torque levels to guarantee correct tightening.

5. Uses

Wing Nuts

Wing nuts are used in a wide range of applications including:

A) Drum Kits: These nuts are used in drum kits to adjust and secure the drum hardware. They serve safe means of tightening and loosening of cymbals.

B) Bicycle Wheels: Wing nuts are used to provide an accessible and convenient way to lock or unlock the wheels. They can be used in a variety of wheel types and sizes. These nuts are also considered a versatile option for wheel configurations.

C) Adjustable Stands: Wing nuts also allow for easy height adjustments in various stands like camera tripods, music stand etc.

D) Assembling Furniture: Wing nuts make it easier to loosen or tighten the furniture components without using any particular tools. They also facilitate easy reassembly and removal.

E) Aerospace: These nuts are used in aircraft equipments that need more strength and reliability. For instance, adjusting mechanism, securing components and others.

F) Industry: Wing nuts provide versatility in industrial materials like securing valves, pipes and so on. They also help in manufacturing steel, brass etc., with different types of threads.

Hex Nuts

Hex nuts are also used in a variety of purposes. These are as follows:

A) Aerospace: Hex nuts are used to withstand extreme temperature, corrosion and vibration in aircraft and spacecraft equipments to secure fastener and bolt from critical applications.

B) Industry: These nuts prevent vibration-induced loosening in machinery components such as in valves, pumps and conveyor system.

C) Piping and Plumbing: Hex nuts ensure a tight seal and prevent leaks from water piping to protect pipe fittings and valves.

D) Automotive: For automotive components like engine mounts, suspension systems and steering equipments, hex nuts help to absorbs shocks and vibrations that provide a secure connection in the metal components.

E) Furniture: These nuts help to prevent loose joints in cabinetry and furniture making like hinges, drawers and so on.

F) Electrical: Hex nuts help to prevent loose connection in electrical equipments such as in outlet covers, lamp bases, switch plates and others.

G) Construction: These nuts also provide a protective connection between bolts and wooden components. For instance, fencing, decking and wood framing.

6. Safety

It is important to follow some safety measures while installing wing and hex nuts to ensure safe use. Some of them are as follows:

- Inspect the wing nut and hex nut if any type of damage or corrosion is there. If you find any, then replace it immediately.

- Store these nuts in a clean and dry environment.

- Securely tighten these nuts and avoid over-tightening which can cause damage, or use calibrated torque wrench for proper tightening.

- To minimize the risk of failure, use high-quality wing nuts and hex nuts.

- To prevent loosening due to movement or vibration, use locknuts or locking compounds.

Closing Lines

Wing nuts are suitable for short-term fastening and adjustments where loosening and manual loosening are crucial. While, hex nuts are widely used for general-purpose applications.

Choosing the right nut for your product needs careful understanding of each nuts. Use appropriate installation methods and follow the torque techniques to secure the nut.