The American Society for Testing and Materials (ASTM) and the American Iron and Steel Institute (AISI) are two of the most powerful groups in creating industry-wide standards. Although the AISI vs ASTM are two groups with similar objectives, their methods differ significantly in some important ways. This blog post will examine those variations and how they affect metal fabricators. Keep checking back!

What Is AISI?

The American Iron and Steel Institute, or AISI, is a trade organization that speaks for the US steel sector. Companies that manufacture steel as well as those who incorporate it into their products are members of AISI. To increase the competitiveness of the American steel industry, AISI is committed to advancing the usage of steel and collaborating with its members. In addition to offering statistical information and industry analysis, AISI promotes research and development in the steel sector.

What Is ASTM?

The organization that produces manufacturing and testing standards for different industries is called ASTM International, or the American Society for Testing and Materials. Encouraging consistency and safety among manufacturers, these standards encompass a wide range of materials, systems, and products.

Difference Between AISI And ASTM

Two organizations involved in the standardization and categorization of materials, especially in the metal and alloy industries, are ASTM (American Society for Testing and Materials) and AISI (American Iron and Steel Institute). The following are the main distinctions between AISI and ASTM:

ASTM (American Society for Testing and Materials)

- Scope: An international standards body called ASTM creates and disseminates voluntary consensus technical standards for a variety of goods and services, including systems, materials, and products. Numerous industries are covered by these standards, including manufacturing, petroleum, and construction.

- Standard Creation: The development of ASTM standards is a consensus-based process that incorporates feedback from technical committees, experts, and industry stakeholders. To guarantee the performance, safety, and quality of materials and goods, the organization seeks to develop uniform technical standards.

- Application: A wide range of materials and products are designed, tested, and have their performance criteria provided by ASTM standards, which are extensively utilized both domestically and abroad. As benchmarks for material attributes and performance assessment, industries and regulatory agencies frequently use ASTM standards.

AISI (American Iron and Steel Institute)

- Scope: The steel industry in North America is represented by AISI, a trade association. Although it does not create standards in the same manner as ASTM, it is very important in determining the objectives of the steel industry, supporting cutting-edge technology, and defending the rights of manufacturers and producers of steel.

- Material Labels: The material designation code system developed by AISI is well-known, especially for steel and steel alloys. These codes—like the AISI/SAE steel grades—are frequently used to classify and distinguish various steel kinds according to their chemical makeup, mechanical characteristics, and intended uses.

- Industry Impact: To solve concerns about the steel industry, such as trade laws, sustainability, and technological developments, AISI collaborates closely with government organizations, legislators, and other industry stakeholders. The company also offers technical assistance and knowledge to support research and development projects about steel.

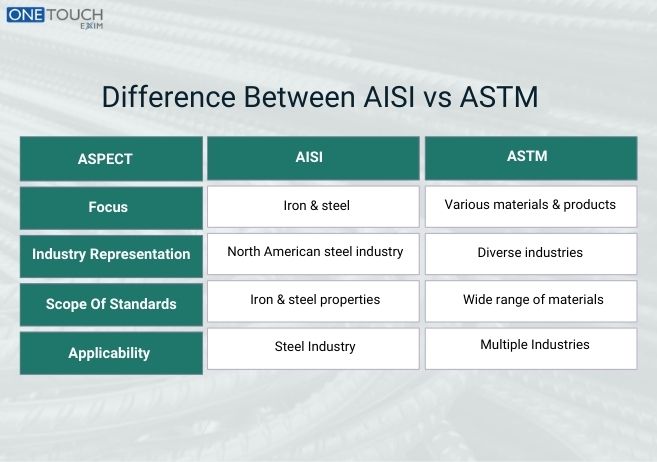

We understand this with the help of the following table:

| ASPECT | AISI | ASTM |

|---|---|---|

| Focus | Iron and steel | Various materials and products |

| Industry Representation | North American steel industry | Diverse industries |

| Scope Of Standards | Iron and steel properties | Wide range of materials |

| Applicability | Steel Industry | Multiple Industries |

Material Selection Of AISI

The chemical composition of carbon and alloy steels is identified by the SAE standard using a straightforward four-digit identifier. It is possible for AISI grades to be quoted as SAE grades, and AISI and SAE standards sometimes use the same steel identification number. Carbon steels and AISI alloy steels are often assigned four-digit numbers. The first two digits in the AISI specification represent the alloying element, the second represents alloy steel numbers, and the final two digits represent the amount of carbon.

| AISI Steel | Index | Specifications |

|---|---|---|

| Carbon Steel | 10XX | Plain carbon steel, Mn 1.00% max |

| Manganese Steel | 13XX | Mn 1.75% |

| Nickel Steel | 23XX | Ni 3.50% |

| Nickel Chromium Steel | 31XX | Ni 1.25%, Cr 0.65 – 0.80% |

| Molybdenum Steel | 40XX | Mo 0.20 – 025% |

| Chromium Molybdenum Steel | 41XX | Cr 0.50-0.95%, Mo 0.12-0.30% |

| Chromium Steel | 50XX | Cr 0.27-0.65% |

Standards Of ASTM

Members of ASTM International work to enhance a wide range of services, systems, methods, products, manufacturing techniques, and material selection for diverse industries by applying trustworthy engineering and scientific practices and using sound judgment.

ASTM is a global organization that develops standards for a wide range of industries and uses, including consumer goods, electronics, energy, medical devices, buildings, paints, textiles, and more.

Top categories are used by ASTM International to group its standards:

- Classifications: Creating systematic classifications based on the attributes of materials, products, services, or systems.

- Guide: Gathered data that offers suggestions for the best possible line of action.

- Practice: Defining methods for carrying out one or more actions without the need for a test result.

Classification of Steel Grades

ASTM and SAE standards specify a letter-numeric rating system for steel grades. To guarantee safer use for producers and consumers, it assesses the qualities of steel and classes any variations.

Several elements influence the steel grading standards set by SAE and ASTM, including:

- Physical Attributes: Material, chemical, mechanical, and metallurgical composition are examples of physical attributes.

- Applications and Production: Construction elements, industrial parts, mechanical components, etc.

- Minimum Ordinary Strength: 34 ksi yield strength.

- Minimum Higher Strength: 46 ksi yield strength.

ASTM Steel Grading

The steel grading system used by the American Society for Testing and Materials (ASTM) is based on a letter and number system. The number denotes the differences based on physical attributes, whereas the letter designates the overall steel type category.

The ASTM uses two common grades for ordinary steel: Grade A and Grade B. Both of these classify mild carbon steel and are slightly different from one another. Both Grade A and Grade B steels have comparable mechanical and chemical characteristics. Because they have different applications, the variations rely on the regulations governing your project or the requirements of society.

AISI Steel Grading

Another body that establishes standards for steel grades is SAE International. The four-digit numerical system used by SAE to classify alloy steel grades is the only distinction between their grading system and that of ASTM.

Because they co-designed its standards, it’s vital to remember that SAE steel grading is frequently referred to as AISI (American Iron and Steel Institute). Thus, when discussing steel grades, you can run into both classifications, such as “SAE 4140 or AISI 4140.”

The SAE steel grades are categorized as follows:

- First digit – Main alloying elements

- Second digit – Top grade elements (tg)

- Last two digits – Carbon amount by weight basis points (wt%)

Conclusion

Two organizations that create steel standards are the American Iron and Steel Institute (AISI) and ASTM International. The two organizations differ greatly from one another, which may confuse purchasers. To help you choose a standard wisely, we’ve listed the key distinctions between AISI and ASTM in this blog post.