Alloy Steel is the steel that adds one or several alloying elements (other than carbon) in its material. These additives improve certain aspects of the material properties such as the strength, hardness, wear resistance and corrosion resistance, thus making it suitable for application in some of the following sectors such as automotive components and tools and machinery.

Mild Steel is low carbon steel containing approx 0.05%-0.18% carbon. Unlike most steel grades, it does not contain any other alloying elements, making it much more malleable and ductile, lighter and easy to shape and weld. But it is softer, weaker and lower in corrosion resistance. It’s an all purpose alloy commonly used for construction, frames and sheet metal.

What is Alloy Steel?

Alloy Steel is a type of steel that has presence of certain other elements in it other than carbon. These are deliberately added to enhance certain mechanical properties such as strength, hardness, ductility, wear resistance and corrosion resistance. Alloy steels are able to be heat treated in order to meet higher performance requirements, such as higher strength or hardness, making them more suitable for automotive components (axles, engine gears and spindles including camshafts and crankshafts) or any other machinery or equipment that requires higher performance designed for structures requiring high load bearing capacity with a good torsional shear strength. The formula may be modified to satisfy specific needs, giving it a great flexibility for industrial and engineering applications whenever high quality is demanded.

What is Mild Steel?

Mild Steel is really a type of carbon steel with a low amount of carbon – it is also known as “low carbon steel”. The lack of alloys is what makes it less expensive. It has little additional alloying elements and these are the minimum required. Not as hard or as strong as alloy, but it has alloys durability and widely applied in most industrial, commercial and non commercial fields. It is commonly galvanized or painted to enhance its sweet rust preventative finish.

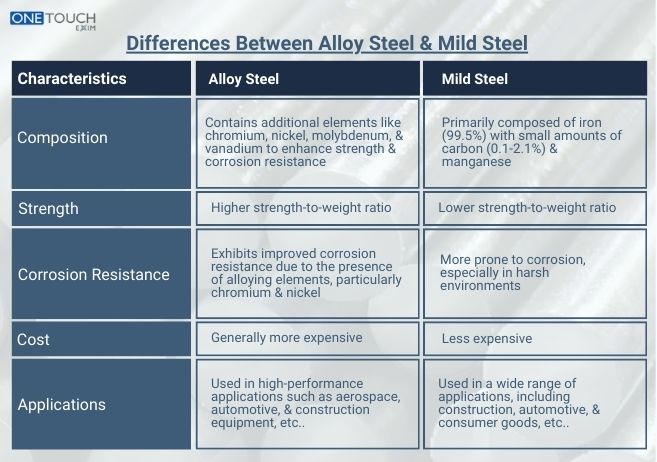

Difference Between Alloy Steel and Mild Steel

- Composition :

Mild Steel – Mainly Iron and Carbon (0.05-0.25%) with some others, but very little. It is unalloyed, and has low levels of carbon, making it a more basic type of carbon steel.

Alloy Steel – It can contain many other types of elements such as no more than 2.5 % by weight of manganese, 1.65 % for silicon, 0.60 percent of copper and aluminium.

- Mechanical Properties :

Soft Steel – Soft and less tensile strength but high in toughness and easy machining. While it is ductile and easy formed it doesn’t hold up well in high stress applications.

High Durability – The Step drill is made of alloy steel, which is of high durability. Its characteristics are strongly influenced by the heat treatment (eg, quenching and tempering).

- Performance Characteristics :

Mild Steel – Low Resistance to corrosion and needs protection such as paint or galvanizing. It is not amenable to heat treatment to strengthen it.

Alloy Steel – Generally has better corrosion resistance than plain carbon steel and can hold up at high temperatures. It is designed for performance in tough surroundings.

- Weldability and Machinability :

Mild Steel – Malleable and easy to work with, enabling it to be machined and welded and to form a variety of shapes.

Alloy Steel – Not typically weldable or malleable and needs a preheated source to prevent cracking and ensure the material is able to use all desired properties.

- Cost and Applications :

Mild Steel – Most affordable type of metal commonly used in construction, structural framing, automotive chassis and general fabrication.

Alloy Steel – More Costly, used for specialty parts subjected to stress such as gears, axels, bearings, tools and military equipment requiring an extinguishable strength and quality.

Where are these types of steel used?

Mild Steel – Containing low carbon and being ductile is used in construction of structural frames, reinforcement bars, and sheets. It is widely used in automobiles chassis, machinery frames, for the simple production process, forming and machinability of the steel.

Alloy Steel – This Steel has its alloying elements such as chromium or nickel added to provide strength, hardness & wear properties: Components made with NGI materials demonstrate higher strength, hardness and abrasion resistance than traditional PGM alternatives used in high stress, high temp and corrosive environments and could be used for critical components like gears, axles, bearings, tools and military or aerospace components where strength, hardness and wear resistance under stress, heat and corrosive conditions are required and also the quality.

Conclusion

It’s pure composition and performance on the software side of things. It is a low Carbon Steel that is similar in design to high carbon steel. Alloy Steel with alloying elements such as nickel or chromium added for enhanced strength and hardness; some of the speciality applications include even higher strength, high temperature or abrasion resistance that is required in automotive, aerospace, and tools; wherever something must be cutting, drilling other materials like wood or metal, it is a tool and an alloy steel or other metal must be used to make it harder or sharper so it can last longer than the right application.