When welding 304 to itself, use a 304/304L filler metal that offers a match for your base metal – a 304/304L chemistry pick-up from view more. This suggestion is due to metallurgical compatibility, which will provide one with a strong, corrosion resistant weld.

Why ER308/L? Corrosion resistance of stainless steel is due to a protective layer of chromium oxide. If chromium does combine with carbon during welding this will lead to chrome carbide precipitation and strip the matrix of chromium resulting in “sensitization” or weld decay (corrosion in the HAZ).

- ER308L (the “L” stands for low carbon, <0.03%) is recommended and the most popular. It’s extreme low carbon content significantly minimizes the possibility of chromium carbide precipitation, which can degrade corrosion resistance of the weld. This is particularly important for welds that are being sent into a corrosive environment or will not be receiving post weld heat treatment.

- Normal ER308 (carb $ -0.08) is also fine, for parts to be annealed after welding, or where extreme corrosion resistance is not required. It can have slightly higher strength at high temperatures but it is more sensitizeable.

Key Considerations :

- Gas : For MIG, short-circuit transfer, an 90% He/7.5% Ar/2.5% CO2 shielded gas is recommended. For spray transfer (MIG), TIG welding; use 100% Argon.

- Special Conditions : To achieve better arc performance and the appearance of the bead of MIG Welding, you can get ER308LSi. The additional silicon improves weld puddle wetting resulting in a flatter bead, better tie in at the toes and less chance of slag inclusion and defects.

- High-Temperature Service : If the final piece is going to be in high temperatures (above 800 degree) then ER308H (high carbon) will be designated, to help increase the strength, but this will be a more distinct application.

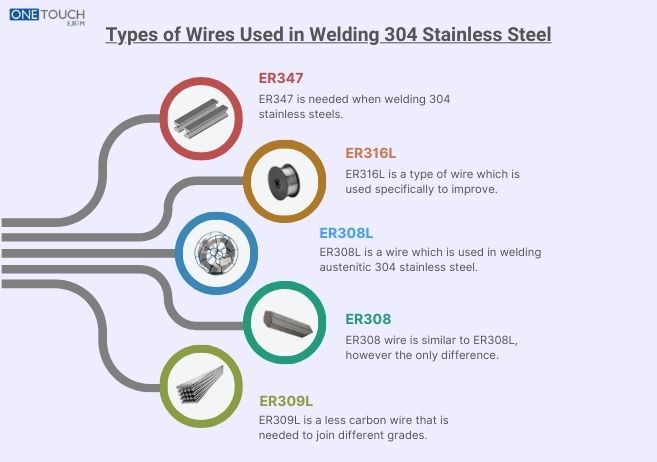

Types of Wires Used in Welding 304 Stainless Steel

ER308/ER308L is the standard and preferred element of 304H welding wire, with a good matching environment, even the better has a deserving recommendation. Now we also have several product list for the 304H low carbon stainless-wire; including : 304H-.04/308H, 308H, 308-16, 308L 21-10N 304 etc.

- ER308L – This is the workhorse wire. The “L” stands for low carbon where 0.03% C,a necessity to avoid sensitisation corrosion, is required in the heat affected zone. It retains corrosion resistance and is best for use in most applications particularly in severe corrosive environments for those not post-weld heat treated.

- ER308LSi – A slightly higher silicon wire of ER308L. The Silicon element enhances the weld puddle fluidity and wettability for MIG welding. The operation produces a less covered and more even and flat end wall and thereby a better tie-in around the edges and less defects. For TIG welding it is not generally recommended. “The increased wetting is great for my stick welding, but generally not for TIG.

- ER308 – The Standard version (non-L) does not meet the (L) grade_> 50K minimum yield requirement. This is applicable for 304 stainless as long as the part will be fully annealed after welding or that the service is not very corrosive. It is slightly stronger at high temperatures.

- ER309/ER309L – This wire is higher in chromium and nickel. You would not choose it for 304 to 304 welding, but it is necessary in two cases:

1 – Unsimilar welding : 304 stainless to mild or carbon steel.

2 – Classing : A coating of stainless steel that is rolled onto carbon steel.

- ER316/ER316L – It is typically used to weld 316 stainless steel and for welding mild steel because its an all purpose rod and It’s not as strong and more prone to cracking in higher strength or hardenable stainless. It is a good choice if the 304 needs a lot of corrosion resistance, such as if it will be in chlorine or some kind of extremely corrosive chemical. “Well, no it is not an average way to.

Should you go with ER308L Wire?

Yes, in most cases ER308L is ideal for welding 304 and 304L stainless steel. It is the recommendation (metallurgical science and practical experience) that have led to data for the production of strong and crack-free as well as corrosion-resistant welds.

Here’s why ER308L is the way to go :

There are two main reasons : First, its low content of carbon (also labelled with an “L” for <0.03%). When stainless steel is heated by welding, chromium may react with carbon to form chromium carbide along grain boundaries. This process, known as sensitization, removes chromium, the element that makes stainless steel resistant to corrosion. The condition is known as “well decay” in which the heat affected zone corrodes and rust develops. ER308L’s very low concentration of carbon reduces the possibility of carbide precipitation at the grain boundaries, caused by chromium carbide forming at the grain boundaries in the presence of less than 0.03% of carbon, which will otherwise form chromium carbide. This is particularly important for applications and exposure to corrosive chemicals, food processing or marine applications, or anywhere the weld will not be post-weld heat treated.

When to consider an Alternative :

ER308L is the default winner, but there are occasions that demand another wire :

- For MIG Welding (GMAW) : ER308LSi. The extra silicon promotes better weld puddle wet-out for a more flat, uniform bead shape with improved tie-in at the toes and fewer problems with rolling and slag inclusions. It is intended for MIG processes.

- Dissimilar Metals : If you are joining 304 to mild steel ER309L is the most commonly used. This higher percentage of chromium and nickel mixes well with carbon steel and does not create a hard, brittle combination.

- For high-temperatures service : If operating temperatures will remain above 800 degree F, ER308H may be called for to provide better high temperature strength, but this is definitely a special-case exception.

Conclusion

Best all round wire for welding 304 SS. Its low carbon level may help prevent carbide precipitation during welding, optimizing the alloy for corrosion resistance in a welded condition. For MIG welding, the type ER308LSi is preferred for its better surface finish and wetting characteristics. Make sure to use the right shielding gas to match the filler metal and obtain a strong, long lasting weld.