Steel is one of the most important elements in construction, infrastructure and in many other industries. It is the fundamental block for building. If you are confused which alloy is better between galvanized steel and mild steel, then you are on the right page. Both galvanized steel and mild steel are a type of carbon steel, but may vary in different factors. In this blog, we will take a quick look at how galvanized steel and mild steel are different from each other. This will help you decide which steel is best for your work.

Comparison Between Galvanized Steel And Mild Steel

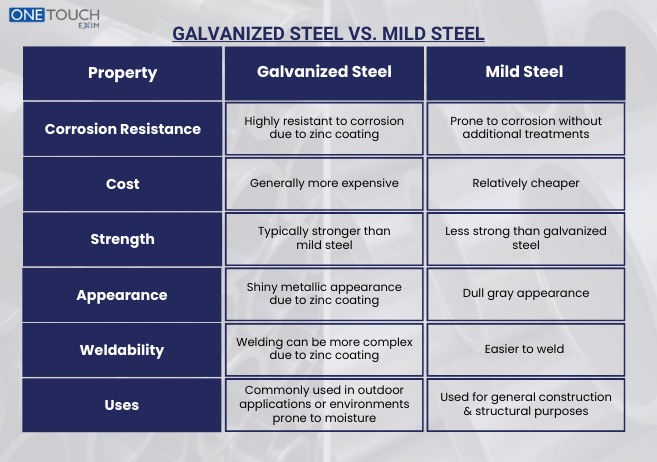

Here is a table outlining the differences between Galvanized Steel and Mild Steel:

| Property | Galvanized Steel | Mild Steel |

| Corrosion Resistance | Highly resistant to corrosion due to zinc coating | Prone to corrosion without additional treatments |

| Cost | Generally more expensive | Relatively cheaper |

| Strength | Typically stronger than mild steel | Less strong than galvanized steel |

| Appearance | Shiny metallic appearance due to zinc coating | Dull gray appearance |

| Weldability | Welding can be more complex due to zinc coating | Easier to weld |

| Uses | Commonly used in outdoor applications or environments prone to moisture | Used for general construction and structural purposes |

1. Definition

Galvanized Steel

Galvanized steel is a type of alloy that is widely used in construction. It is corrosion-resistant and can be used in places with moisture without catching rust and corrosion. It is a highly used alloy because it can withstand harsh environmental conditions and is very durable.

The main elements of galvanized steel are iron and zinc. However, it may contain other elements in low content like manganese, silicon and others.

Mild Steel

Another name for mild steel is low-carbon steel. It is a type of carbon steel with very low content of carbon that is around 0.05 % to 0.25 %. It is more malleable than other categories of carbon steel.

Different grades of mild steel are named by the AISI (American Iron and Steel Institute). The different grades of mild steel are: AISI 1008, AISI 1010, AISI 1015, AISI 1018, AISI 1020; and the other two are S275 and S355.

The main contents of mild steel are iron-ore and carbon. It may also contain other elements but in a very less amount like sulfur, manganese, silicon, phosphorus and others.

2. Properties

Galvanized Steel

Properties of galvanized steel are:

- Galvanized steel is less malleable when compared to mild steel.

- Density of galvanized steel is between 7.8 g/cmᵌ and 8.03 g/cmᵌ .

- Galvanized steel is corrosion-resistant and can be used in the atmosphere with moisture.

- The zinc layer increases the longevity of galvanized steel.

- It gives a shiny metallic finish and can be used for making decorative items as well.

- It is recyclable which also makes it an environment-friendly choice.

- Galvanized steel is weldable.

Mild Steel

Mild steel has many exceptional properties like:

- It is highly malleable and can be shaped as desired.

- Density of mild steel is approximately 7.75-8.08 g/cmᵌ.

- Mild steel is magnetic in nature.

- It is prone to corrosion, making it unsuitable for places with moisture.

- It is one of the most affordable alloys.

- It is highly weldable and is great for fabrication and other purposes.

3. Strength and Durability

Galvanized Steel

The tensile strength of galvanized steel is between 399 MPa and 550 MPa (58,000-79,800 psi). Due to the layer of zinc, galvanized steel is more durable than mild steel. It can be used in the atmosphere with moisture without getting rusted or corrosive.

Mild Steel

The tensile strength of mild steel is between 400 MPa and 550 MPa (58,015-79,770 psi). Mild steel is less durable in comparison to galvanized steel. This type of steel is prone to rust and can get rusty and corrosive easily when exposed to both moisture and oxygen.

4. Castability

Galvanized Steel

Galvanized steel contains high content of carbon and has a high melting point in comparison to mild steel. These properties make the castability of galvanized steel very low.

Mild Steel

Unlike galvanized steel, mild steel has a very low content of carbon and it is also very ductile. These properties make mild steel castable.

5. Corrosion-resistance

Galvanized Steel

Galvanized steel can become corrosion-resistant with the coating of zinc. The zinc coating acts as a protective layer on the galvanized steel’s surface to prevent it from rusting. It is suitable for application in places with moisture, saline water and humidity.

Mild Steel

Mild steel is not suitable for conditions like humidity, moisture etc., because it has a poor corrosion resistant property. It is prone to rusting and can easily get rusty when exposed to both oxygen and moisture. Mild steel requires a protective layer to protect it from rusting.

6. Uses

Galvanized Steel

Galvanized steel has a protection layer of zinc which makes it an anti-corrosion alloy. It is used in various industries, especially in places that are exposed to moisture where mild steel can’t be used:

- Galvanized steel is used in construction especially in roofing.

- It is used for building columns and bridges because it is durable.

- It is used for making automobile parts that need corrosion resistance like underbody parts, body panels, exhaustion parts like mufflers and exhaust pipes etc.

- It is used for making fences.

- Electric poles are also made of galvanized steel.

- It is used for making storage tanks and pipelines because it has non-corrosive properties which makes it durable for a longer period of time.

- It is used for making outdoor furniture (for example, benches in public parks) and decorative items.

- It is also used for making several items for home etc.

Mild Steel

Mild steel has exceptional properties and it is also very affordable. This is why it is used in various fields like:

- It is used to make building blocks in construction.

- It is used in the aerospace industry because it has a high strength-to-weight ratio.

- It is also used in making parts of automobiles like gears, shafts, doors and others.

- It is also used in making important medical equipment like X-ray and MRI machines, stretchers, tables and beds.

- It is used for making home decoration items because it is malleable and can be easily shaped without any damage.

- Mild steel is not only used outdoors, it is used in making non-stick cookware as well.

- It is used by engineers for making pneumatic and hydraulic parts, bolts and many other things as well.

- Mild steel is also used for making heavy machines like agricultural equipment, shipbuilding etc.

7. Cost

Galvanized Steel

Galvanized steel is coated with zinc to prevent it from corrosion. This makes it more pricey in comparison to mild steel. It can be five times more expensive than mild steel.

Mild Steel

Mild steel is one of the most inexpensive alloys. It is a budget-friendly choice, but it may be prone to rust. It cannot be used in areas that have oxygen and moisture.

Galvanized Steel or Mild Steel: Which One is Better?

So, the decision of which alloy is better depends on the work that needs to be done. If you want it for the place that is exposed to moisture and oxygen like underparts of your car, or table and chair for your garden etc., you should choose galvanized steel. Galvanized steel is corrosion-resistant which makes it more durable compared to mild steel when kept in moisture.

On the other hand, if you want steel for indoors or areas that are not exposed to moisture you can choose mild steel. It is affordable than galvanized steel and has all other qualities like ductility, castability etc., except being corrosion-resistant.

To sum it up, if you want to choose steel for outdoors or areas near water go for galvanized steel. And, if you want steel for indoor construction choose mild steel, it is budget-friendly and durable.

Conclusion

Both, mild steel and galvanized steel have their own unique properties. While one is corrosion-resistant, the other is not. Also, one is more ductile than the other one. You can read the properties of both the alloys in the above blog and decide which alloy is more suitable for you as per your requirements.