The aluminum flat stock bar comes with several outstanding properties like durability and can stand firm against weight. So, this bar is often used to cut other metals to their desired length, drill, or weld into place for a substructure or frame. Some general utilization of this bar is support braces, ladder hangers, gate latches, ductwork, overhead doors, bracing, and more. It is available in an array of sizes and thicknesses and can be modified to achieve the determined needs of any application. It is also inexpensive in proportionate to other metal bars, making it a cost-effective option for various tasks.

Aluminum Bar, A commonly uses metal components in various fields. This bar exaggerates its strength, sturdiness & capability to develop several uses in various industrial, commercial & residential applications. Their high uses in various applications make them a popular choice for manufacturing & production processes. If you are also considering the aluminum bar & want to know how to bend the aluminum flat bar, this information will be helpful for you.

The manufacturing industry makes use of this metal bar for fabrication and structural applications because of its lightweight character, excellent strength-to-weight ratio, and corrosion resistance. The most common grades of metal flat bars are 6061, 5052, and 1060, each with distinct properties that make them appropriate for various purposes.

Bending aluminum flat bars is a versatile skill for DIY enthusiasts and metalworkers alike. It allows you to create custom brackets, supports, and other structural elements for various projects.

Understanding of Aluminum

Before diving into bending, let’s understand the material. Aluminum is a soft and malleable metal, making it relatively easy to bend compared to steel or other metals. However, it’s crucial to choose the right type and temper for your project. Common aluminum alloys are:

6061: Strong and versatile, suitable for various applications.

5052: Excellent corrosion resistance, ideal for outdoor projects.

1100: Softest and most malleable, good for simple bends.

The temper refers to the aluminum’s workability and strength. O temper (soft) is easiest to bend, while H temper (work-hardened) is more resistant to bending but requires more force.

Aluminum Flat Bar Bending Techniques

Now, let’s explore various techniques for bending aluminum flat bars:

Manual Bending

- For Gentle Curves: Use your hands or a vise to gradually bend the bar. Mark the bend line beforehand for accuracy.

- For Sharper Bends: Clamp the bar in a vise & use a hammer and block of wood to bend the aluminum flat bar progressively.

Bending Jig

- Simple Jig: Create a V-shaped notch in a block of Wood to guide the bend and prevent kinks.

- Advanced Jig: Construct a jig with adjustable stops & rollers for precise and consistent angles.

Bending Tools:

- Pipe Bender: Choose a bender with a V-groove die suitable for flat bar width.

- Brake Press: Offers precise control & wipes sharp bends for thicker bars.

Hear Assisted Bending:

- Torch: Use a propane torch to gently heat the bend area (avoid overheating). This softens the aluminum for easier bending without losing strength.

- Heat Gun: A safer alternative to a torch, but requires more time & control.

Aluminum Flat Bar Bending Safety Tips

- Wear gloves & eye protection when working with metal.

- Clamp the bar securely before bending to avoid accidents.

- Bend gradually and avoid applying excessive force to prevent cracks.

- Ventilate the area if using a torch to prevent inhaling fumes.

Tips for Achieving the Best Metal Bar Bend

- Multiple passes with the bending tool can make you get a sharper bend.

- For thicker or wider bars, using moderate heat before bending can prevent cracking.

- Start with a 90-degree bend before attempting extra complicated bends.

- Consider the usage of a bending Jig or brake for more correct outcomes.

- Avoid overbending the bar to prevent cracking.

- Consult a qualified & experienced technician if you are uncertain or worried about something.

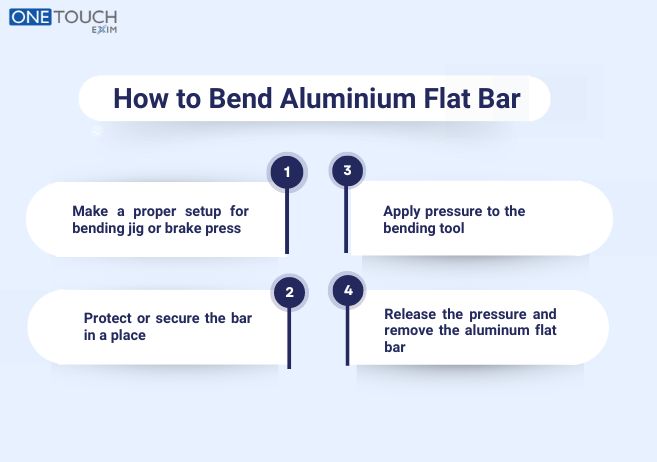

In Conclusion, The above-mentioned best buyer’s guide to flat bar bending techniques can be useful for professionals and beginners in their required operations. Bending an aluminum flat bar is a relatively simple process, but it takes practice to get it perfect. Whether you are a professional or a beginner, this manual equips you with the information to make informed selections and achieve a better effect in your bending operations.Here are a few steps to follow if you wish to bend an aluminium flat bar with precision. Pick your first soft, easily machinable grade such as 6061 or 3003. Harder alloys may require annealing; heat the bar with a torch to 350 degree celsius and let it cool down to room temperature to soften it and prevent cracking.

Place the bar securely in a heavy vise with soft jaws or under wood blocks to prevent marring. If you need a clean and sharp bend don’t be so lazy, grab your bending brake. A hammer and wood or metal, form block will suffice for light curves or basic bends. Bend against the grain for best results to prevent cracking.

Minimum bend radius is very important as it needs to be at least equal to the bar thickness to prevent cracking on the outside. For instance a ¼ inch thick bar has a minimum ¼ inch inside radii.

Work carefully and check the angle often with a protractor. There is going to be spring back so you might want to over-bend just a little bit to get to your final angle.

Understanding of Aluminum

Light, strong, silvery-white metal with a high strength-to-weight ratio and excellent resistance to corrosion. This resistance is due to a passive oxide layer that form immediately on its surface in airspace that protects the remaining metal. It is also ductile and malleable and is good conductor of heat and electricity.

Aluminium is a relatively youthful industrial metal – it is never found in its pure form, but rather as an alloy with likes of copper, magnesium, silicon, and zinc. The alloys of the subject invention have all been classified in series that were substantially intended to improve the mechanical properties of the aluminium, such as strength, hardness, and workability.

This attribute of the new material makes it powerful in any field. In the aerospace and auto industries, its lightness adds fuel economy. For building, it also offers long lasting, weather-resistant cladding and framing. It is non-toxic and resists most chemicals, which is why it is used to package food and alcohol.

With its high energy consumption during manufacture (secondary to the high energy input which was lavish by the standards of the day) and transportation expense that entails, primary aluminium production is one of the most environmentally damaging industrial activities. However, aluminium is 100% recyclable and experiences no loss of properties or quality, regardless of the application and the stimulus to recycle it is a three fold environmental and sustainable advantage; not only is the demand on primary intelligence and material reduced, the life of the original piece of aluminium is extended; less becomes waste, this is directly a more sustainable path forward.

Aluminum Flat Bar Bending Techniques

Choose a ductile material such as 6061 or 3003. For more severe tempers, annealing is necessary. Now heat the blend section uniformly to approx 350 degree and only when the soot mark disappears remove and allow to fully cool – this will facilitate the bending process.

Bending Methods :

- Vise Bending – Use when you want sharper, more crisp bends. Secure the pipe tightly in a vise with soft jaws to avoid marring. Using a mallet (or a secondary bar as an overhang point), apply firm continuous pressure beyond the bend line.

- Bending Brake – This is the perfect tool for accurate, sharp 90 degrees bends. It grips the material and raises it up above a bending leaf in order to create a clean, sharp line.

- Bending – For in curves or shapes formed. Use a solid form block of the desired radius as a mandrel. Using your hands or a mallet, bend the bar around it gradually.

Simple Factor : Remember to always bend across the grain! The inside and outside should be of minimum ⅛ inch radius to prevent the outside of the bar from cracking. Compensate for springback by bending slightly beyond your target angle.

Aluminum Flat Bar Bending Safety Tips

Ensure you wear safety glasses to protect your eyes from the metal fragments or a snapping workpiece. Gloves should be made of sturdy fabric, cut resistant and a good fit to protect hands from sharp edges, burrs etc, but not so loose that gloves may get caught in equipment. Wear steel toe cap boots to protect your feet.

Work & Tool Safety : Make sure your workspace is clean from any clutter, have good lighting and your tools are in order. Bolt your vise or bending brake securely to a substantial work table. Check that the tool is not damaged and do not use jewelry or loose clothing. When annealing make sure that you have proper ventilation, you use a fire extinguisher nearby. Watch out for hot metal after you have heated it – make sure to label it and let it cool all the way down before touching it.

Precaution : Plan to bend safely in order to control and eliminate any awkward position. Apply continuous and gradual pressure and don’t be too forceful. After the bar is cut, remove all sharp edges and burrs in a good and careful manner. Lastly, watch for crush points between the bar and your tools that could lead to severe hand injuries.

Tips for Achieving the Best Metal Bar Bend

When you need a clean, precise bend in a piece of metal, a bar folder is the way to go.

Material Preparation – Begin by choosing the right alloy : 3003 or 5052 aluminium and low carbon steel are very soft. With harder metals such as spring steel or some aluminium tempers, annealing must be done. Heat the particular bend area uniformly to critical temperature and slowly cool it down to soften so that it won’t break.

Tool to Select & How to use : Choose the right tool for the application; hydraulic benders work best for large bars and CNC machines, while a good old hammer and vise works well for sharp angles, and a mandrel is best for smooth curves. Beburr edges

Conclusion

You can’t bend an aluminium flat bar easily unless you anneal it. Avoid the impact, use a good vise and plenty of control pressure with a mallet or vise. Remember to bend standing perpendicular to the grain to avoid splits and allow for springback by over-bending slightly.