Metal forming is a fabrication process. In general, metal-forming is the most widely used manufacturing process. Metal forming is performed in the primary processes of extraction, and casting. And before the finishing processes of metal cutting, grinding, polishing, and painting. It’s a process that creates structural parts and components out of metal sheets or tubing.

Metal forming is a manufacturing process involving the manipulation of metal sheets, bars, or billets to achieve desired shapes and dimensions. Metal forming the temperature increases, the yield strength decreases while the ductility increases. This processes usually produce no scrap and generates the final part geometry in a very short time. Metal-forming plays a vital role in manufacturing and shaping raw metallic materials. Metal forming processes the right balance between the strength of the material and its formability.

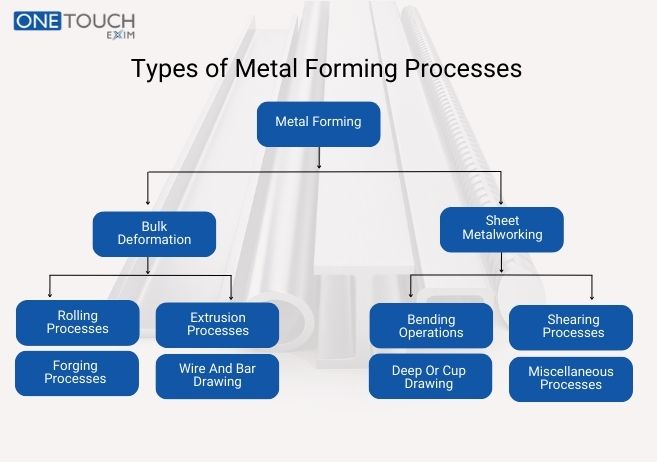

Types of Metal Forming Processes

In manufacturing industries, there are a range of metal-forming processes that are utilized for mass production. Metal forming processes are three types-

1. Bulk Forming Processes

Bulk-forming processes involve shaping raw materials with a low surface area-to-volume ratio. This category encompasses processes like rolling, forging, extrusion, and drawing. Different forces, such as compressive, tensile, shear, or a combination of these, are applied during bulk deformation.

2. Sheet Metal Processes

Sheet metal forming works with sheets, plates, and strips and primarily utilizes tensile or shear stresses. Its operations, including bending, drawing, shearing, blanking, and punching, are often carried out utilizing hydraulic or pneumatic presses. In these sheet metal procedures, die and punch sets are utilized.

3. Powder Metal Forming

One emerging class of procedures with unique features is powder metal forming. By producing parts almost to their final dimensions, this technique (near-net-shape forming) reduces material waste. It is possible to produce desired mechanical properties by adjusting the mix of materials by powder formation. When it comes to powder formation, sintered metals are more formable than traditional wrought materials. The difficulty, though, is in reducing or completely eradicating porosity because it can worsen strength, ductility, and corrosion resistance as well as raise the possibility of premature component failure.

Metal forming processes are classified according to the type of deformation force applied to the material during forming.

These types are as follows: Casting, Stamping

Advantages of the Metal Forming Process

Additionally, the metal-forming process has multiple advantages which are as follows:

- This process is simple and Versatile

- It has an extensive Product Range

- Enhanced Strength and Durability

- Broad Applicability

- Efficiency

- Speed and Cost Savings

- Diverse Material Properties

- Complex Geometric Shapes

- Rapid, Strong Shaping

- Improved Strength

- Reduced Scrap Costs

- Cost-Effective Process

Applications of Metal Forming Process

Applications of metal form processes across industries include the following:

1. Automotive Manufacturing

A crucial part of the car manufacturing industry is metal forming. Many cars incorporate sheet metal parts that are carefully formed using various metal forming techniques. This procedure is essential for creating complex parts with complex curves and contours, such as body panels for automobiles.

2. Aerospace Engineering

Aerospace engineering uses metal forming extensively in the manufacturing of fuselages, wings, and engine sections, among other airplane components. Although composite materials are also used in the production of airplanes, metal is chosen over composite for the construction of fuselages and engine components due to its superior strength.

3. Construction

Construction applications need the use of metal forming techniques, especially when fabricating pipelines. Depending on the desired shape, either hydraulic or electric resistance techniques are used to create metal pipeline tubes. The potential of a newly developed method called air-forming to create seamless pipelines has gained popularity and improved pipeline integrity.

4. Press Working

Under the general heading of press working, metal forming includes a variety of metalworking techniques such as squeezing, stamping, and bending. These methods, which are widely used in many industries, make it possible to fabricate and assemble a wide range of parts and goods. In metal forming, there are two main methods: hot and cold forming. In contrast to cold forming, which uses force to deform the metal without heating it, hot forming requires heating the metal to a pliable state before shaping. Bending and press working are two of the most popular applications.

Conclusion

Flexible tools are used for a variety of metal forming operations, including bending, drawing, embossing, blanking, piercing, and bulging. The book includes detailed descriptions of these procedures as well as their outcomes. Parts with more consistent wall thickness and less spring back and wrinkling can be produced because elastic tools apply pressure to the workpiece with a more uniform exertion.

Friction-assisted deep drawing procedures allow for the production of deeper cups since the favorable friction postpones the beginning of wrinkling and fracture. Moreover, a blankholding force can be created by the friction that forms between the metallic components and the rubber pad.