Steel is one of the most useful and important materials in construction and other industries. There are different grades and types of steel. The two most used types of steel are mild steel and carbon steel. Both mild steel and carbon steel have their own specialties, properties and uses. One of these steels have high strength while the other has high ductility. In this article, we will learn how mild steel and carbon steel are different from each other.

COMPARISON BETWEEN MILD STEEL AND CARBON STEEL

1. Definition

What is Mild Steel?

Mild steel is a type of carbon steel. It is also called low-carbon steel because it contains less amount of carbon that is approximately 0.05% to 0.25%. It belongs to the category of carbon steel. It has a low content of carbon which makes it easy to form this steel into various shapes and sizes without any breakage. It is ductile, weldable and comes in low price as compared to other alloys.

It is a combination of two elements, iron and ferritin. Other elements may also be present in mild steel but in a very low quantity. These elements are manganese, silicon, copper etc. Mild steel is classified under the AISI (American Iron and Steel Institute) system.

Here is a list of different types of mild steel along with the carbon content present in them:

- S275 – 0.18%

- S355 – 0.02%

- AISI 1008 – less than 0.01%

- AISI 1010 – 0.08% to 0.13%

- AISI 1015 – 0.13% to 0.18%

- AISI 1018 – 0.15 to 0.20%

- AISI 1020 – 0.17 to 0.23%

It is affordable and has exceptional properties which makes it an ideal choice for many people.

What is Carbon Steel?

The main alloying element of carbon steel is carbon. Other elements are also used in carbon steel but they have low content in comparison to carbon.

The other elements that may be present in carbon steel are manganese, sulfur, silicon and phosphorus. These elements define the properties of carbon steel.

Carbon steel is classified in three different categories depending on the carbon content present in them. All of these categories have different properties and their own specialty.

- Low-carbon steel – It is also called mild steel and contains a very low amount of carbon content. It is ductile and can be shaped in different sizes and shapes without any damage.

- Medium-carbon steel – It is harder but brittle as compared to low-carbon steel. The carbon content present in medium-carbon steel is somewhere between 0.3% and 0.6%.

- High-carbon steel – As its name implies, high-carbon steel contains a higher amount of carbon content as compared to other carbon steels. It contains 0.6% to 1.5% of carbon. The high content of carbon makes it hard and limited to forming into different shapes.

2. Process of Making

Both mild steel and carbon steel have the same procedure of making. The first step is extraction – where iron ore and coal are extracted from the earth. Then they both are melted together in high temperature which forms into pig iron. Pig iron is then ladled and tapped.

After all this, pig iron is refined through the process of BOF (basic oxygen furnace) to remove all the impurities. Later, a finishing touch is given where the steel is coated to prevent the chances of corrosion.

The key differences are of carbon content, alloying element and heat treatment:

- Mild steel has low carbon content, whereas carbon steel has high content of carbon.

- Carbon steel may contain extra alloying elements to enhance its properties like manganese, silicon and chromium.

- Mild carbon steel requires less heat treatment to get desired shape and size, whereas carbon steel requires more heat and effort.

3. Properties

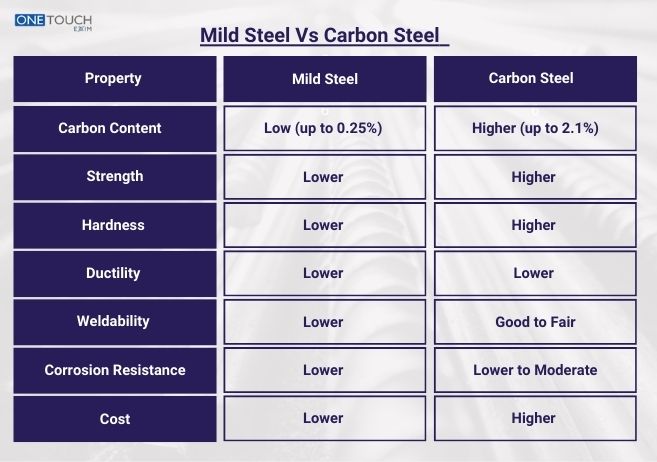

Both, mild steel and carbon steel have different physical properties due to the presence of carbon content in them.

Mild Steel

- Mild steel is ductile and thus can be shaped in desirable size.

- It is weldable and machinable, due to its low carbon content.

- Mild steel contains high amounts of ferritin and iron which also makes it magnetic.

- Density of mild steel is between 7.75 g/cmᵌ and 8.08 g/cmᵌ.

- It has microstructure which makes it soft and easy to weld.

- It is affordable in comparison to other types of steel.

- It has poor corrosion resistance.

Carbon Steel

- Carbon steel is hard and tough as compared to mild steel.

- Ductility of carbon steel is moderate.

- It has a high content of carbon because of which it has high strength but poor weldability.

- It can easily get a rusty coat if kept in a place which has moisture or humidity.

- Density of carbon steel is somewhere between 7.9 g/cmᵌ and 8.23 g/cmᵌ.

- It can be costly as compared to mild steel.

- It has low corrosion resistance, the same as mild carbon steel.

3. Uses

Here are the different uses of mild steel and carbon steel:

Mild Steel

Due to its exceptional properties like ductility, weldability and others, that too in an affordable price makes mild steel a popular choice in many industries. There are many uses of mild steel, for example:

1. It plays an important role in building blocks and thus is used in making frameworks and structures.

2. It is used in making non-stick cookware. Mild steel retaliates the heat which provides safety when using such utensils for cooking. They are also very easy to take care of and require less effort to clean them.

3. It is used in aerospace industry for its high strength-to-weight ratio. It is used in making engine blocks, stringers, cylinder heads, nuts and many other things.

4. Used in general engineering for making columns, bolts, pneumatic and hydraulic parts, casting dies and for many other things.

5. Mild steel is also used for making medical equipments like MRI and X-ray machines. Not only these but it is also used for making beds and stretchers etc., for hospitals.

6. It is widely used in making doors, gears, steering knuckles, side rails and other things in automotive industry.

7. It is used in construction and infrastructure due to its ductile property.

8. It is not only used in making heavy machinery and tools, but also used in making home decor items.

9. Also used in making pipelines because of its durable strength.

Carbon Steel

Carbon is tough and thus used in various industries. Here is the list of uses of carbon steel (both medium-carbon steel and high-carbon steel).

1. It is used in making railway tracks and wheels of the train.

2. In construction, carbon steel is used in making structural buildings and bridges.

3. It is used in making cutting tools like knives, blades etc., because of its high tensile strength.

4. It is also used in making appliances that we use in our daily life, for example, washing machine, fridge and many others.

5. It is used in making heavy tools and heavy machinery because of its toughness.

6. It is used in automotive factories for making gear, shaft and other necessary parts.

7. It is also used for making wires that are high in strength.

8. It has the ability to maintain sharp edges, and thus used for making milling cutters.

Conclusion

Both mild steel and carbon steel have their own properties which makes them suitable for various purposes. Mild steel is ductile and can be shaped easily as desired. On the other hand, carbon steel is tough and can be used for building strong blocks of foundation etc. You can choose any of them as per your requirements.