| Alloy Basis | C – 4.0 to 5.5% Max, Cr-20 to 25%. |

| Hardness | 69 – 71 HRC |

| Hardness Resistance at High Temperature | Up to 250 to 300°C |

| Cutting | Plasma Cutting & Water Jet Cutting |

| Cold Forming Minimum Radius | Minimum Radius: 150 mm (For 6+4) Using Hydraulic Press to bend |

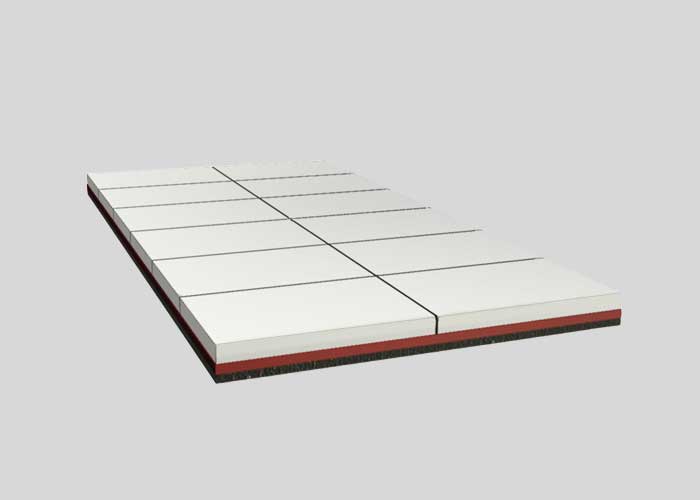

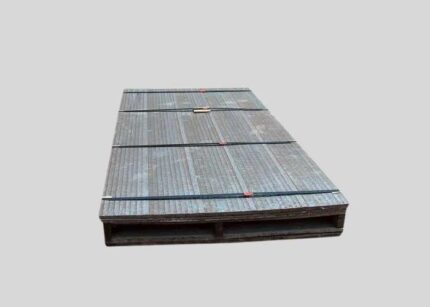

OTEP 70C

OTEP 70C wear plate is a high-strength steel plate intended for applications involving very high wear and abrasion. Heat-treated wear plate Brinell hardness, in the range of 477 to 534, is considered quite durable material for use under severe working conditions. This grade of wear plate has more resistance against impacts and thus provides longer service life, showing excellent performance in mining, construction, and heavy machinery. We are manufacturers of OTEP 70C Plates in India, offering a wide range of wear plates. Order now the Best Durable OTEP 70C Wear Plates from One Touch Exim.

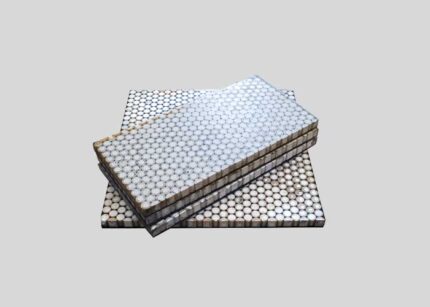

Category: Ceramic Wear Plates

Description