Working with hard metal such as Stainless Steel is not easy due to its sterling & hardness property. As we know SS metal contains the components of Chromium & iron that give them great hardness & durability. Stainless Steel pipe Cutting is usually a difficult & slow task especially when you use an ordinary SS pipe-cutting tool. They also may be a cause of accidents. Also, it’s not possible to use the industrial machine to cut Stainless Steel pipe every time. To make this difficult task easy, here in this blog we have shared information about the steel pipe-cutting tools & processes you need to follow. So let’s start,

List Of Required Tools You Need To Cut Stainless Steel Pipes

Below is the list of required tools to cut SS pipes, check now

- Pencil, chalk, and marker for making a mark cut on the steel.

- Meter stick and ruler for measuring the pipe.

- An angle grinder, steel pipe cutter, chop saw, circular saw, band saw, jig saw, and a hacksaw for cutting plasma.

- Belt grinder and file for deburring the pipe.

- Safety gear for eye protection, ear protection, and gloves for hand.

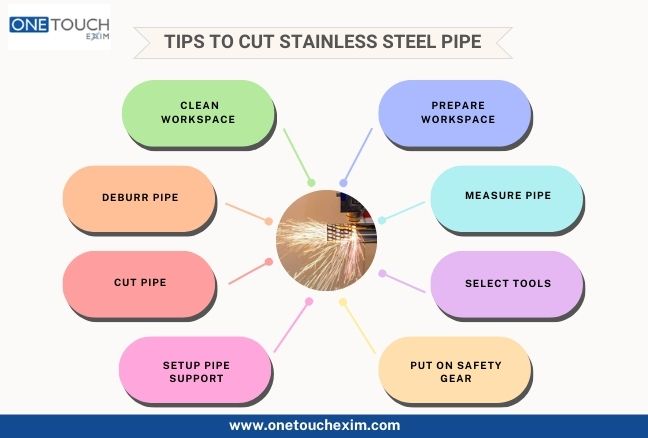

How To Cut Stainless Steel Pipe- Steps You Need To Follow

Check the steps, process & preparation tips you need to follow during the cutting of Stainless Steel pipes.

Prepare workspace

The very first thing, you need to find a space to cut Stainless Steel pipes. The space should be empty including there were no harmful materials & no fire or health hazards around. The work must be performed very safely & with protection. Also used the Stainless Steel cold cutting method which is only spark.

Measure the SS pipe before cutting

The accurate measurement of SS pipes before cutting is very important, it helps to cut pipes in perfect length & dimension. For correct measurement, mark the should be visible clearly. Marking in the pipe before cutting will help to cut SS pipes in size.

Selection of tools to cut SS pipes

We have multiple tools to cut the stainless pipe. So we have to select the best tool for our job. There are many different types of tools that are used in stainless steel.

Angle Grinder: Cutting stainless steel pipe with an angle grinder can be used for many jobs like polishing, cutting metal, etc. Spend your money on a diamond disc because it is capable to cut stainless steel metal.

SS pipe cutter: The ss pipe cutter is specially designed for cutting stainless steel pipe. It is difficult to find the tube cutter which has the right size for your pipe. They are easy to use and produce clean and precise cuts.

Chop saw: Chop saw is a type of saw which is quick and clean cut. It is a good choice for stainless cutting pipe and it produces fewer sparks than other saws.

Circular saw: The circular saw is less expensive. It produces more sparks as compared to a chop saw and it is difficult to use.

A band saw: Band saw is a cheaper saw and it works on the continuous loop of the blade to cut the metal.

Jigsaw: A jigsaw is a less expensive saw as compared to a band saw. Jigsaw causes more spark than the band saw and. it is easy to use.

Hacksaw: Hacksaw is easy to use and it generally specifies the design of the cutting metal and it produces a clean cut.

Plasma cutter: Plasma cutter is fast in use. It is used for the plasma torch to cut through metal and they provide expensive plasma.

Put on the safety gear

Before using the tools to cut Stainless Steel pipes, safety is a highly considerable point. A few safety rules you need to follow- Eye protection, Ear protection & Hand gloves. Otherwise, its loud sound or spark may harm your Ears & Eyes.

The setting of pipe on pipe support

Whenever we cut the pipe, we have to support the pipe from the both start and end side and set it properly. Check the support wheel of the pipe contact. It works on a flat surface and properly arranges the pipe while cutting stainless steel.

Attaching the pipe saw to pipe

Set the pipe into the gripper by rotating the pipe diameter and the position of the pipe saw on the top of the pipe. So the pipe edge lower blade is on the cutting mark. By the adjustment of the gripper, the firm grip can be easily fit and cut. Now the pipe is ready to cut.

Deburr the pipe

After cutting the pipe we need to remove the edge sharp. Which is also called deburring. It is performed by two methods :

A belt grinder is the best way to cut stainless steel pipe sharp edges. And it can easily deburr the pipe. But it can be more expensive.

A file is used to remove the deburr straightforwardly until you are not satisfied. It is a cheaper alternative and more time-consuming.

Clean the pipe and workspace

Now the pipe is cut and deburred. It’s time to clean the pipe and the workspace. Fir remove all the metal residue and debris from the workspace. It’s better to clean with a vacuum cleaner but you can also use a broom. Then use a cloth to wipe down the pipe and remove residue.

In Conclusion

Cutting Stainless Steel pipes is not an easy task without proper knowledge that how to cut Stainless Steel pipes. In the above blog, we have shared complete information about cutting steel pipes including information about SS cutting tools & tips. I hope the above information will be useful for the user & make their work easy.