Steel pipe is a vessel used to transmit the fluid or gas which contains the fluid. It is of a nominal size designation and its approx inside diameter maintains approx the same fluid capacity regardless of schedule (wall thickness). It is normally used in water lines, gas lines and plumbing applications.

Steel tube is a welded structural grade tubing that is available in either type A513 or A500 Grade B, depending on it’s size and wall thickness. It is sized to specified outside diameter and wall thickness. Tubes have tighter dimensional tolerance and can be cold-rolled but come with the option to have a variety of customized shapes (a square, oval, rectangular, or round). They are applied to applications such as precise strength machinery, frames and hand rails.

Steel Pipes

A Steel pipe both serves as a vessel and a channel for conveying gas or liquid under pressure. Its main purpose is to size the pipe uniformly, but it also minimizes flow resistance and it is priced more economically using NPS.

Available in different “schedules” (i.e. wall thickness) for pipe, it is made from carbon or stainless steel. It’s strong and most of the time it is soft enough to be welded into practically endless shapes for bigger industrial applications like bridges and buildings. Steel pipe is used in extensive applications such as water mains, oil and gas lines, piling and fire sprinkler systems; where the pipe must serve well mechanically in order to provide a source of reliable internal fluid capacity.

Benefits of Steel Pipe

Steel pipe provides great strength – even under severe working conditions – including very high pressure and heavy load and high impact situations. Its lifetime durability and resistance to failure due to deformation, plus its low cost maintenance ease of replaceability makes it an economical long term value for critical infrastructure. Material is also available in multiple specification material, structural pilling and multiple end finish options. The steel pipe has applications in the constructions, transportation, chemical, energy plant and other industrial subjects. And by recycling, steel pipes help improve the efficiency of construction and save natural resources. This toughness, flexibility and environmental soundness cements its role as an essential workhorse for contemporary industry and building.

Steel Tubes

A steel tube is a hollow cylinder or a tubular section with the surrounding of its outer diameter and walls being uniform and precise in terms of its dimension. Unlike pipe, its sizing does not refer to nominal diameter size but it is specified by the outside diameter and the wall thickness with physical dimensions. Tubing may be coldrolled and a smooth surface finish is also associated with uniform wall thickness.

They are typically characterized by being dimensionally stable and uniform in shape; this is important for applications that require high dimensional accuracy and mechanical strength. Round, square, or rectangular steel tube rounds out the selection for frames and roll cages but it is normally used directly to plumb a system as also favored when one’s design has specific dimensions requirements, tight radius bends or needs structural support in addition to fluid transfer capability.

Benefits of Steel Tubes

Steel tubes provide good strength and excellent dimensional properties. As it is strong and lightweight, with a great strength to weight ratio, this material can support heavy loads without excessive bulk, explains marketing manager Richard Jooste. Offered in different shapes – round, square, rectangular – the new material allows the sleek modern designs seen in architecture and machinery. Uniform dimensions and minimum finish allow ideal adjustments in fabrications and installation. Tubes are also extremely resistant to shock and torsion stresses making them ideal for safety and mechanical applications. This mix of accuracy, strength and design flexibility can make steel tubes a versatile material for automotive and in many other fields such as motorcycle frame making.

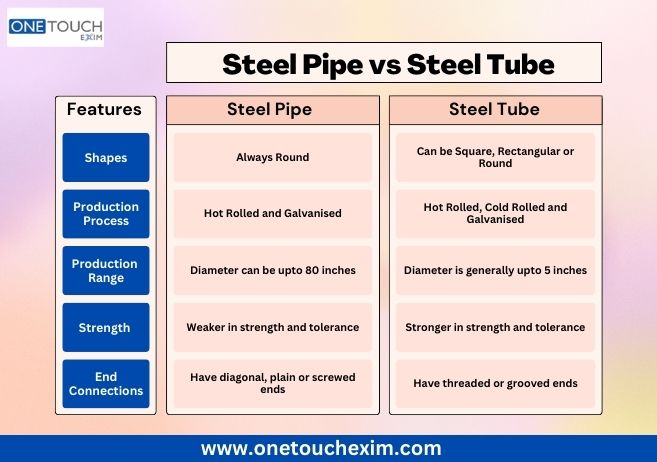

Difference Between Steel Pipe and Steel Tube

The main difference between steel pipe and steel tube is that Steel pipe is widely used for pipeline transportation such as oil. Its size stems from its nominal bore (NB), which is the approx internal diameter and schedule both of which are needed for pressure containment and fluid flow.

Steel Tube is a structural shape if it is used as a column or a stringer. It has a high strength to weight ratio, is resistant to many forms of corrosion and is a durable material. Its attributes are physical – valued for a strength-to-weight ratio and quality of construction, framing and machinery in brief; pipe is measured by its interior, tube is measured by its exterior.

Conclusion

Steel pipe size and pressure rating are its capacity for conveying fluid. A tube of steel is a structural component that has tight tolerance in terms of its external diameter, mechanical properties and the ease to fabricate. It’s the application that tells you: flow or fit and form.