Metal plays a significant role in different products by providing strength, conductivity, electromagnetic shielding, efficiency, durability, corrosion resistance etc. However, choosing an optimal material for your product is a crucial decision.

Steel and aluminum are the two most widely used and produced metals that offer unique qualities that allow them to be used in a variety of applications. Both are somehow similar in terms of certain conditions, but they have distinct characteristics which separates them from each other.

In today’s blog, we will uncover detailed differences between steel and aluminum, the two popular metals with factors like strength, cost, weight etc. This will help you to determine an appropriate component for your product or as per your requirement. Let’s begin!

Comparison Between Steel and Aluminum

Steel and Aluminum are two of the most widely used metals in various industries, including construction, transportation, and manufacturing. While both metals have their own unique properties and advantages, there are some key differences that set them apart.

1. Overview

Steel

Steel is also known as alloy steel. Iron and carbon are combined together to produce steel. Its unique mixture of strength, affordability and durability makes it one of the most widely utilized materials in the world with a wide variety of applications.

Steel is a high tensile-strength alloy. The carbon content in steel determines the hardness, ductility, and ability to transmit heat. It has also tendency to react with elements like water, acid etc.

Other materials present in steel are mentioned below:

- Silicon

- Iron

- Carbon

- Phosphorous

- Sulfur

- Manganese

- Vanadium

It is used in various industries like infrastructure, automotive, construction, manufacturing, electrical appliances etc.

Based on chemical composition, physical properties and applications, this metal is classified under different grades by numbers and letters. Among many steels, the ‘304 stainless steel’ category is a versatile and widely used alloy. It has high ease of weldability, fabrication etc.

Aluminum

Aluminum is the most widely used industrial metal with unique chemical and physical properties. It is the third most abundant metal found in the Earth’s crust. It forms an oxide layer that protects its surface when it comes into contact with air.

Its lightweight, robust texture, electrically and thermally conductive, and heat resistant properties make it a vital raw material for the advancement of manufacturing. Aluminum has lower density as compared to other metals.

Components which are present in aluminum are as follows:

- Manganese

- Zinc

- Copper

- Silicon

- Lithium

- Magnesium

- Tin and nickle

In addition, this metal also comes under various grades like 6061, 5052, 7075, 1100 and so on. The most commonly and best used alloy is the aluminum 3003. This comes with moderate strength and better resistance to corrosion. It can be used in various applications like building sectors, outdoor projects and many more.

Aluminum is used in a wide range of applications. For instance, finishing and architectural applications, mechanical equipment, transportation, appliances, sports equipment and many more.

2. Strength

Steel

If there is a heavy process involved in making your product, then steel is the best choice in terms of strength. Steel is stronger and heavier than aluminum. The estimated tensile strength of steel is typically around 500 MPA (Megapascal).

The essential factor while considering the strength of steel is malleability. However, steel does not have sufficient amount of this feature. In order to increase its malleability, it goes through a process called annealing, in which the hardness of the metal is reduced by heating and cooling to increase its productivity.

After this process, steel may acquire the desired form of shapes, sizes and can also be bent.

Aluminum

Aluminum is more ductile and malleable that allows it to withstand stretching without cracking or fracturing. This property helps in forming and shaping of material.

Even though, the tensile strength of aluminum is less than steel, its distinct properties makes it stronger in terms of strength. Aluminum is also suitable to tolerate cold weather conditions.

3. Corrosion and Rust Resistance

Steel

Steel has a high amount of chromium that generates an oxide coating which protects it from corrosion. It generates its chromium shield as it rusts, making it appropriate for products involving severe chemical or salt. However, not every steel has this degree of resistance to corrosion.

Aluminum

Aluminum has a natural oxide coating that occurs on the surface to make it naturally resistant to corrosion. This oxide layer stops more oxidation or corrosion. Since rust is primarily caused by iron oxide that accumulates on steel, aluminum does not rust.

4. Uses

Steel

Steel is used in numerous applications by many industries. Some of the uses are mentioned below:

1. Bridges and buildings: Due to its resistance to corrosion and durability, it is suitable for constructing bridges which can hold to harsh environmental conditions. This metal is also utilized in constructing architectural components like roofing, cladding etc.

2. Transportation: Steel’s tensile strength allows it to be used in transportation in automation industry like engine components and body panels. Also, in aircraft industry including landing gear, wings and frames, and many more.

3. Medical Equipment: This metal is also used in surgical tools like scissors, forceps and surgical implants including bone plates and joint replacements.

4. Kitchen Utensils: It is used in making utensils as steel is durable and resistant to corrosion.

5. Other applications: Steel is also used in oil and gas industry producing pipelines etc. Some other applications include railings, food processing, cranes, composers, generators and so on.

Aluminum

Aluminum is also used in a wide range of applications. They are as follows:

1. Construction: It is used in constructing walls, windows, staircases, shelves, railings etc., because of its corrosion resistance and lightness.

2. Electrical: Aluminum is widely used where the distribution of power line is long because it possess great electrical conductivity. It also reduces the loss of energy during transmission.

3. Automotive: It is used in many automotive applications including wheels, brakes, suspension components etc.

4. Aerospace: This metal is also used in aircraft wings, fuselage and so on.

5. Cost

Steel is more budget-friendly than aluminum. Depending upon the global demand and iron ore availability the prices of steel may fluctuate in comparison to aluminum. Aluminum is considered to be more expensive than steel because of its raw material costs. However, at the end cost becomes a significant factor depending upon the product you have chosen.

Aluminum or Steel, Which Metal is Best for your Product?

Here the question arises, which metal is best for your product? So, while choosing the right metal for the product which you want to form, it is important for you to note that the decision must depend on your project’s requirement, your assets or budget and the forming process. In certain situations, before buying some people find it difficult what to choose between these metals. Therefore, it is essential to consider the factors of the metals which you will be using in the process of making your product, otherwise the wrong metal may not give you the desired result.

Aluminum and steel both have their advantages and strengths, and are considered to be suitable for a wide range of products. Steel is denser and has a higher strength, but it has poor corrosion resistance. This metal is utilized when you want your product to be used in dry and clean environments. Whereas, aluminum is generally less denser than steel. However, it exhibits perfect corrosion resistance. This metal is a best choice if your product may be exposed to corrosive substances or harsh environments.

Steel might be a preferable option if the strength, durability and resistance to large loads are requirement for your product. But aluminum might be a better choice if you need a lightweight, formable material that resists corrosion. The choice ultimately comes down to the special qualities and intended use of your product.

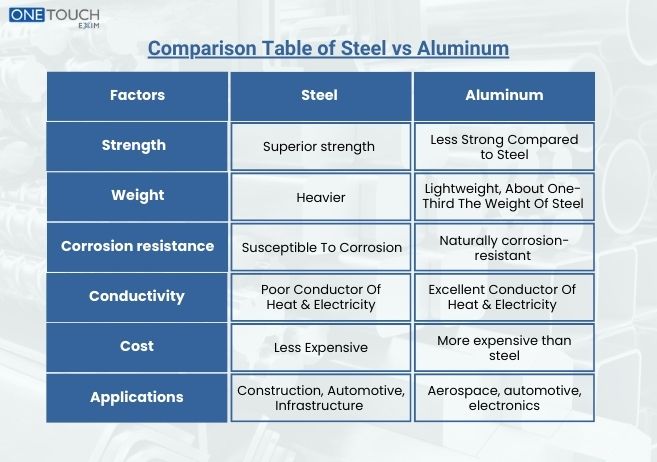

Comparison Table of Steel vs Aluminum

Here’s a comparison table of Steel vs Aluminum for various factors:

| Factors | Steel | Aluminum |

| Strength | Superior strength | Less strong compared to steel |

| Weight | Heavier | Lightweight, about one-third the weight of steel |

| Corrosion resistance | Susceptible to corrosion | Naturally corrosion-resistant |

| Conductivity | Poor conductor of heat and electricity | Excellent conductor of heat and electricity |

| Cost | Less expensive | More expensive than steel |

| Applications | Construction, automotive, infrastructure | Aerospace, automotive, electronics |

Conclusion

Steel and Aluminum are the two materials that are widely used in manufacturing because of their corresponding qualities. Understanding these metal’s differences will help you to decide which one to use for your product.

Aluminum is lighter and more conductive making it a better choice for electrical applications than steel. On the other hand, due to the strength and ability to withstand corrosion and heat, steel is used in processing equipment and engines.

Sure! Here’s a comparison table of Steel vs Aluminum for various factors:

| Factors | Steel | Aluminum |

| Strength | Superior strength | Less strong compared to steel |

| Weight | Heavier | Lightweight, about one-third the weight of steel |

| Corrosion resistance | Susceptible to corrosion | Naturally corrosion-resistant |

| Conductivity | Poor conductor of heat and electricity | Excellent conductor of heat and electricity |

| Cost | Less expensive | More expensive than steel |

| Applications | Construction, automotive, infrastructure | Aerospace, automotive, electronics |