Drilling into Stainless Steel takes selecting the precise drill bit. The metal’s toughness and durability of hardness is more when strained demands attention. Standard high-speed steel bits will swiftly become blunt. Opt instead for cobalt steel containing five to eight percent cobalt, providing outstanding heat resistance and hardness for extended use. When drilling stainless, titanium nitride or titanium or titanium nitride coated bits offer an exceedingly durable, heat-resistant surface minimizing friction wear. Proceed at low speed under steady pressure with suitable chip-removing liquid to overheat and avoid work hardening throughout the cut. With the proper bit and care taken, stainless steel can be penetrated.

Key Factors for Drilling Stainless Steel

Successful drilling stainless steel requires managing its tendency to work-harden and its high strength. The primary factors, bit selection, speed, pressure, and cooling necessitate careful consideration.

Drill Bit :-

Drill is related to certain qualities to withstand the demands of stainless steel. Standard high speed steel bits are simply inadequate for the task. Optimal performance stems from a bit constructed of cobalt steel, fortified with 5-8% cobalt for enhanced heat resistance and durability. Taking drilling to another level are bits coated with titanium aluminum nitride. This extremely hard, slick surface reduces friction and heat build up, enabling clean penetration of the tough material. The bit must terminate in a sharp point to initiate cutting instead of skating across the surface.

Speed and Feed Rate :-

Low RPM is essential. This is because at such revolutions per minute this generates a lot of heat which further hardens the steel, which is why such bits quickly go dull. Feed with a constant, vigorous pressure to keep it cutting; insufficient pressure only will harden the surface enough to prevent any further cutting.

Cooling and Lubrication :-

We can bend a lot of things. Application you must use a dedicated lubricant when machining for cooling and lubricating the workpiece and cutting bit. Features and benefits ;- No work-hardening ;- Longer bit life ;-clean, burr-free holes. Use plenty of spirit on every step of the process. I also like to give the hard surface a little love-tap with a center punch just to create a starter indent, which should keep the bit from wandering.

Different kinds of drilled metals

To succeed at drilling metal you need to get three things right: The speed or RPM of the drill bit, the pressure you exert on the drill bit and the lubricant you use to cool the bit while you drill (see how to drill metal for drill speeds).

Soft Metals (Aluminum, Brass, Copper) :-

These materials are similar to plywood but pose some unique issues. Aluminum is soft and gummy, causing standard bits to dull teeth and clog up with material resulting in poor hole quality and slower penetration. (HSS) bits do quite nicely if they have a polished flute and a sharp high rank angle (such as bits intended for wood) – this all helps to frown on chip welding. Brass and copper are notorious for making bits “grab” or dig in, typically as the bit penetrates the work. It also requires a less aggressive rake angle in the bit (and probably even some grinding off a flat on the cutting edge) and a good rigid clamping of the workpiece, of course, in order to avoid this.

Hardened and Alloy Steels (Stainless, Tools) :-

This category is the hardest on your equipment. Stainless Steel work-hardens very quickly due to friction heat, causing standard bits to wear and break off. COBALT (HSS-Co) – coated are a must. Are hard at high temperatures. For digging in hardened material, opposite end to end, with long; slow spiral, high feed pressure as well as ample and slow side cutting oil will penetrate work hardening materials without effort and with reduced curl. Tool Steel is frequently pre-hardened and demands even stronger bits such as solid carbide or high end cobalt.

Cast Iron :-

Gray Cast Iron is soft, yet abrasive, because of its graphite flakes. It makes fine abrasive dust, not chips. HSS bits will do but carbide tipped bits offer better wear. Coolant is not commonly used as it makes the dust into a grinding paste, so it is best to drill dry and brush the dust clear.

General Steel (Mild Steel) :-

It is the softest and most forgiving metal to drill. Regular HSS bits should work just fine. This trick is to go at a nice steady but slowish pace with even pressure and to take all of the chips in one cut.

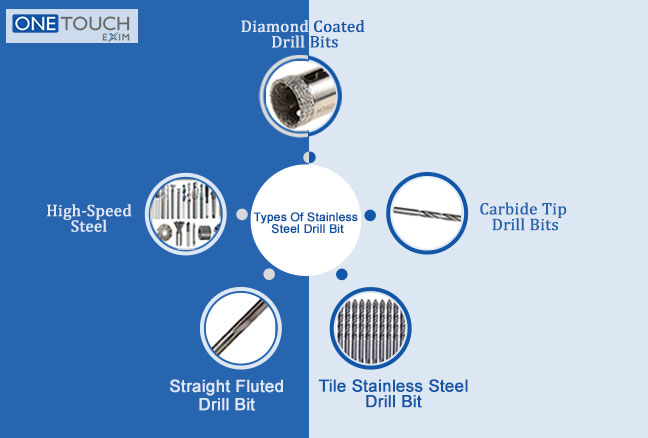

Choosing the Right Drill Bit

The proper choice of drill bit is essential to obtain performance and the cleanest end product. The most important is the material you are drilling.

Wood :-

Use brad-point or spade bits to make clean tight holes. Masonry bits made of steel (and tipped with carbide or diamond) this is the right bit if you are ripping through concrete, stone or brick and need to use the hammer setting of a drill.

Metal :-

The selection goes by hardness. All purpose holes standard High-Speed Steel (HSS) bits work well with soft metals, such as aluminium or mild steel. For tougher metals including stainless steel, spring for a cobalt (HSS-Co) or TiAIN bit, which are more resistant to heat and abrasion and therefore can be run at faster speeds than uncoated HSS.

Be sure you properly match the shank of the bit to the chuck and use a sharp one, always. Regardless of bit type, a poor bit will take more effort to use and will generate more heat and poor results.

Conclusion

Drilling a metal hinge depends on choosing the right bit for the particular properties the material holds. Regular HSS bits will do the job for soft metals and mild steel, but hardened alloys like Stainless Steel take heat-resistant cobalt or TiAIN-coated bits. Well, it’s a sharp bit, for proper drilling speed & keeping the pressure straight. One necessary, non-negotiable step that must be taken is one of ensuring the use of proper cutting fluid for cleanest finishes and maximum tool life. right drill bit for steel is crucial for achieving accurate results which has been discussed in 10 tips for drilling stainless steel.