It is really important to choose the right welding cable for safety, performance and efficiency. The first is current : anything that passes from the cable current amounts should have a thicker diameter to counteract overheating and voltage drop, both of which may damage equipment and adversely affect the stability of an arc. Cable length is also important with longer runs requiring larger gauges to maintain voltage. Always reference a welding amperage-distance chart. To give another example a 200-amp welder will need 1/0 AWG wire if it has a length under 50 feet, since the larger 2/0 AWG would restrict the power flow.

What is Welding Cable?

A welding cable is a specifically designed type of power lead. Unlike regular electrical wire, it offers super high strand count copper wire that is extremely flexible for easy weaving and bending so it can withstand wear and tear from pulling and dragging across construction sites. Its insulation consists of high quality EPDM which resists damages caused by temperature, oil and abrasion and on top of that its super strong and does not suffer from sparks or sharp edges. This special design guarantees a secure and proper transfer of the welding high current’s intensities.

Different Types Of Welding Cable Insulations

The insulation of a welding cable is most often classified by its material and each type provides different attributes.

EPR (Ethylene Propylene Rubber) :-

This is the most popular because of its strong resistance to heat and oil, excellent flexibility and good durability from weathering. It does not harden in extreme cold.

Neoprene :-

Neoprene is very abrasion, cut through and flame resistant and used in the harsher industrial applications but is generally less flexible than EPR.

SBR (Styrene-Butadiene Rubber) :-

This offers similar overall durability at a more affordable price point, but fares less-well in extreme cold where it can stiffen and crack.

What Cable Size Should You Choose?

Choosing welding cable size (AWG) is based on amperage and duty cycle of the welder with cable length being the key. For longer runs the wire should be larger to prevent voltage drop due to resistance and overheating. Be sure to refer to your welder’s manual for ampacity and duty cycle recommendations. General rule of thumb is #4 AWG cable is good for 100-amp output, for runs of 50 feet or less. For 200 – amp output #2/0 AWG is generally typical.

Never, ever use undersize cable; It is a fire hazard, Always go thicker and heavier gauge for safety and better operations.

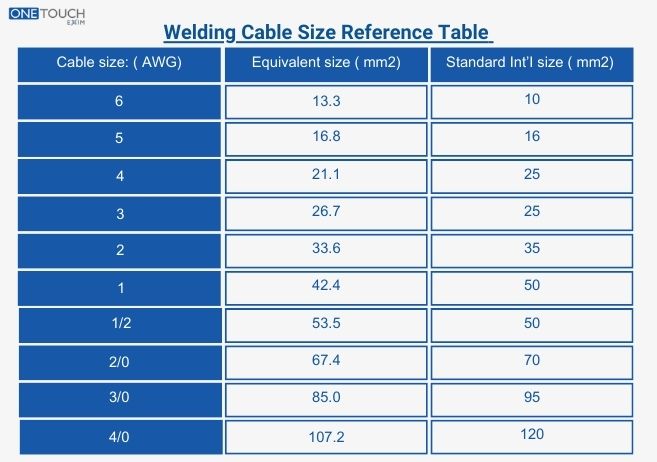

Welding Cable Reference Table

Welding Cable size charts is an indispensable tool for choosing the right wire AWG size. It compares amperage output, duty cycle and total cable length (both leads added together) to establish a minimum safe gauge.

If the wire gauge is too small for the amount of current and length of wire, dangerous voltage drop or equipment damage may result. Per the table, with the same amperage, the longer circuit will need a thicker wire in order to keep to the same performance. As always, make sure to reference the manufacturer’s recommended table values as the recommendations can be slightly different depending on the particular insulation and construction standard.

The Concept Of Welding Cable “Ampacity”

Welding Cable ampacity is the maximum current that a cable can handle without its temperature rising above its safe operating temperature. Unlike typical wire, it’s characterized by a duty cycle – the percentage of a 10-minute cycle it can operate under load.

Its duty cycle is 60% which means it can operate for 6 minutes then needs to cool for 4 minutes.

Effective ampacity drops under higher ambient temperature or under bundled cables. Ampacity is exceeded by overheating, deterioration of insulation, causing a fire hazard and damaging equipment. You should always select the cable size (AWG) that is large enough so that the output amperage of the welder does not exceed the rated amperage of the cable at your particular duty cycle.

Extension Cables

A Welding Extension cord should be a welding cable not a run of the mill extension cord. The ampacity and duty cycle must be equaled or surpassed over your welder equipment’s original leads.

The determining factor is voltage drop. For longer extension you have to over achieve the cable gauge (AWG) to compensate and keep the arc performance. For example if you double length, you might have to go up two wire sizes.

Always use fully insulated, Heavy duty connectors rated for the amperage. If you use a too-small, lightweight extension cord the odds you will have it melt, overheat become a fire hazard and produce a lousy, unstable welding arc.

Conclusion

A Welding Cable size chart, along with a wire size chart and the right table guides, are essential for the safe operation. These references are the critical components linking the amperage and cycle of your welder along with the overall length of your circuit to determine the lowest safe gauge. In all cases, these charts should be the final arbiter when it comes to choosing the appropriate size. The one thing to remember is long runs require a higher diameter cable to offset voltage drop. By making sure you have the right size, you can avoid the risk of dangerous overheating, keeping your equipment safe while ensuring you can create the best arc possible.for their specific projects. Additionally, the right care and maintenance of the cables are critical for their sturdiness and safety.