An electrode is a term that encompasses any consumable or non consumable conductor used to make a component of a welding circuit. A welding rod is a type of filler metal that is applied in a manual process to join two pieces of material through a molten weld pool. With stick (SMAW), What is referred to as the consumable “Welding Rod” is more accurately referred to as a stick electrode since the “rod” conducts current and melts to become filler metal. All electrodes are rods, but not all rods(eg. Gas welding rods) are electrodes, so likewise all welding rods are electrodes, but not all electrodes separate the core from the covering, no matter how you define it, it remains a rod.

What is a Welding Rod and Electrode?

Welding electrodes is a basic part of arc welding, guiding electric arc from welding machine to base metal. In the stick welding process (SMAW) the electrode is a metallic rod that has been covered with a flux. It serves as filler metal, while the liquified metal flows from both workpiece to fill the joint between them, and the flux coating of the electrode disintegrates creating a shielding gas while also adding ingredients to the weld to increase its mechanical properties. Thus, a “Welding rod” is usually neither an electrical conductor, nor a source of material to the joint, but serves only as a metallic electrode through which the current passes.

Characteristics of Welding Rod

Stick Electrodes or Welding rods have some key features. The material of the core wire (eg.mild,stainless) will determine the properties of the weld metal. The flux coating is critical : It stabilizes the arc, generates shielding gas from vaporization, creates a slag layer to protect the newly cooling weld and can include deoxidizers and alloying elements. Classification numbers (like E6013) refer to tensile strength, position and flux type. Other important characteristics are diameter (for amperage range) , deposition rate, and ease of use (arc stability , slag release). These properties determine whether the rod is ideal for use on particular metals, joint types or both and in all welding positions.

Characteristics of Electrode

Welding Electrode will be designated by type, classification and the type of coating. The number (eg. E7018) indicates tensile strength (70,000psi), position (1 for all) and type of flux. The Base metal and the core wire have matching alloys. The Flux coating is key : It helps stabilize the arc, provides generation of shielding gas for displacement of the atmosphere, creates the slag and alloys to the weld metal. The primary operational features are arc stability, penetration (deep vs soft), deposition efficiency and slag removal. These characteristics define the performance a particular electrode is capable of for specific applications, materials and welding positions.

Applications of Welding Rod

Welding is made more efficient with super welding rods such as stick electrodes that are widely recognized for their portability and flexibility and have been used in the construction and pipeline welding, ship building and heavy equipment repair. This also means that they can weld outdoors without wind affecting their welding or on dirty, rusty metals – something the gas -shielded process does not handle well. Typical uses are the erection of steel structures tying together cross country pipelines, maintenance and repair work (MRRO) in industrial environments. Types of rods are selected based on the properties desired in the weld, for example E6010/11 for deep penetration and 7018 for high strength structural welds or stainless, hardfacing rods for repairing specialized alloys.

Application of Electrodes

Depending on the type, the application of welding electrodes is enormous. Stick electrodes are the most likely choice for application in countless fabrication shops, construction sites, structural steel work and for repair and maintenance work. On the other end non consumable electrodes such as tungsten (GTAW/TIG) are mandatory for thin, exotic or critical nuclear/aerospace application or anywhere the highest weld quality and process control must be maintained. Wire electrodes (GMAW/MIG). There are driving considerations in automotive, transportation and fabrication shops, as they provide high-productivity and high-deposition rates on clean sheet metal and steel.

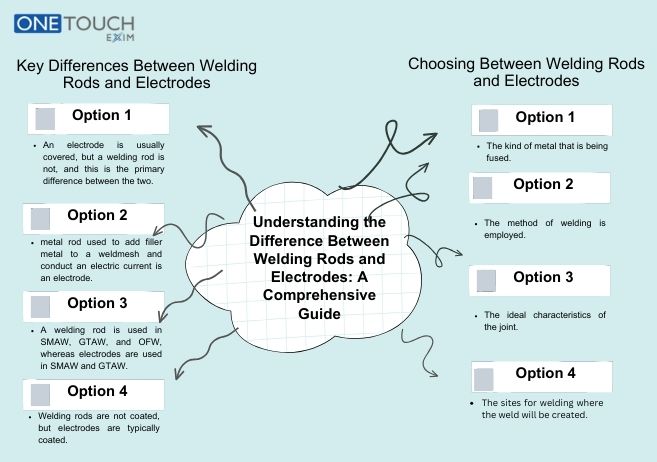

Choosing Between Welding Rods and Electrodes

A rod is one type of electrode in a process like a stick (SMAW). The true choice is a choice of welding process. Select Stick Electrodes for mild and low alloy steel welding that’s commonly found on the farm or ranch where iron and steel join together. Choose an MIG wire or flux-core wire for fast and clean welds. For auto body work or any type of thin metal, you have to use a MIG wire or flux core. Choose TIG tungsten electrode for superior precision on thin materials such as exotic metals, aluminium and stainless for space frame, aircraft, nuclear and artistic sculptural application in which weld quality and appearance are important.

Conclusion

A “welding rod” refers to a form of filler metal that is specific whereas the “electrode” is what actually conducts the current. The Stick (SMAW) electrode is consumed as filler. But not all of these electrodes are rods (i.e. not MIG wire or TUNGSTEN). So all Welding rods used in arc processes are electrodes, although the word “electrode” applies to all sorts of parts, not just rods and describes what they do rather then their shape.