A kind of steel that contains chromium and is immune to rust and tarnish. Stainless steel is formed of iron and carbon in two steps, just like all other types of steel. Chromium (Cr) and other alloying components, such as nickel (Ni), are added to stainless steel flux core wire to make it invulnerable to corrosion. In terms of commercial uses, stainless steel is an alloy that furnishes exceptional deterioration resistance, durability, and aesthetic captivation. Stainless steel’s diverse composition of components is primarily responsible for its attributes.

Because flux-core penetrates deeper than sticks do, can a welder weld flux-core welding wire be stronger than sticks for the same size weld? Mig is the master of thin material. Flux-core welding wire price also varies and comes in dozens of varieties, both gas- and self-shielded. To have an apples-to-apples comparison, you must also compare the same mechanical properties. In out-of-position applications or when welding on thicker metals, take into consideration the use of gas-shielded flux-cored wires. On gas-shielded flux-cored wires, the flux layer solidifies more quickly than the molten weld material. It consequently forms a ledge to support the molten pool when welding vertically up or overhead.

What Wire Do You Need For Flux-Core Weld Stainless Steel?

Obtaining the appropriate welding wire is the first step in using a flux core to weld stainless steel. Flux core welding wire manufacturers manufactured the wire for the welding purpose. Unfortunately, standard steel applications shouldn’t be performed with the welding wire. Rather, a unique alloy is required for the filler material in stainless steel. The precise alloy completely relies on the kind of stainless steel that we are using.

Finding The Correct Wire

Determine and check the inventory of stainless steel welding wire you’re welding before searching for the appropriate wire. You should be able to identify new stainless steel by its three-digit number. Low 300s to 400s are typical ranges, though they can go higher. Contact your source for more information if you’re still unsure about the sort of stainless steel you have. Finding a will flux core weld stainless steel compatible welding wire is possible once you know the matching number. The fact that the metal’s number and the materials should match makes this procedure fortunately fairly simple.

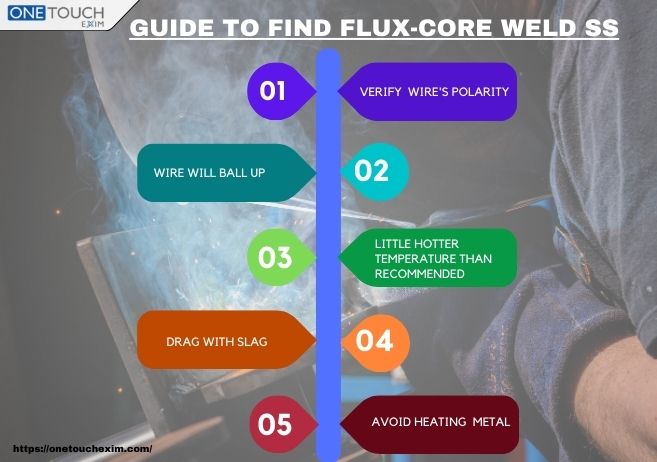

There Are Guides To Find The Flux-Core Weld Stainless Steel

Examine the few guide to find stainless steel welding flux. It addresses several typical issues and solutions. If you run into issues, you might even wish to refer back to them:

1. Verify the wire’s polarity

There are some ways to determine the polarity of the wires:

- Check the polarity if you start trying to run a bead and find that it pops a lot and is hard to maintain an arc.

- MIG and flux core welders can weld stainless steel with flux core wire run on DC electro-negative (DCEN) or DC electro-positive (DCEP) power.

- Whether the wire is positively or negatively charged depends on the setup.

- Though most stainless flux-core wire requires DCEN, some, like Blue Demon, actually require DCEP, much like MIG.

2. The Tip Of The Wire Will Ball Up; This Is Fine

The wire may have a little ball on the tip when welding stainless steel with flux-core, which is an oddity. It’s not unusual to have a ball form on the end of a piece of ordinary flux core, but it can weld stainless with flux core, which means you’re moving too slowly. You will even see the ball bouncing at the end of the wire when we can you mig weld stainless steel with flux core wire running a bead.

3. Operate At A Little Hotter Temperature Than Recommended

Compared to mild steel, stainless steel has distinct characteristics. The filler substance is also variable, in addition. You might use a flux core to weld stainless steel and discover that your welder’s settings chart is a little inaccurate.

It makes perfect sense because stainless steel needs a higher amperage setting. To fine-tune your welder’s settings, simply increase the amperage a little and perform a few test passes on a piece of scrap steel.

4. You Drag With Slag

The pros and cons of pulling or pushing a weld are frequently disputed. These principles hold for procedures such as MIG and TIG, but you have to pull when it comes to flux core. The likelihood of flux inclusions is reduced by dragging your weld. When flux fragments become stuck in the weld or beneath the slag, a weld fault happens. As a result, the weld has porosity, which can use flux core wire to weld stainless steel degrading the weld’s appearance and jeopardizing its structural integrity.

With this method, you can you flux core stainless steel to push your weld, but you have to make sure the wire stays on the leading edge of the puddle at all times to avoid the previously described weld flaws. Because the push technique necessitates a greater skill level, it is usually advised to drag with slag.

5. Avoid Heating The Metal

Heat causes discoloration in stainless steel. You must be cautious not to overheat your welder when using stainless steel, even though you weld stainless steel with flux core mig will need to increase the current. It’s common to have some discoloration that seems rainbow-colored. However, excessive heat causes the stainless steel to oxidize, making it rust-prone. Keep the material’s temperature below 800 degrees.

Conclusion

There is some disagreement concerning whether or not you can welding stainless to mild steel with flux core. Some individuals say it is achievable, while others contend it is incomprehensible. Eventually, it relies on the type of welding equipment you are using and the grade of your welds.

Yes, fluctuation core wire can you flux weld stainless steel be utilized to weld stainless steel. Stainless steel is continuously welded utilizing flux core welding, specifically in circumstances where operating a shielding gas would be demanding or impracticable. When heated can you weld stainless steel with flux core wire, a flux compound found in flux core wire produces a protecting gas that supports the weld clean and vigorous by containing the contamination. Just be sure you use the right flux center wire that is made specifically for soldering stainless steel.