The key distinction being the design and applications. Hex nuts are for general applications and are used with bolts and washers of the same finish. Wing nuts have two large, flat sides so it can be easily twisted by hand and it can be easily by tool or wrench. This makes them well suited for applications that need to be modified often or quickly disassembled,such as the cases on lights, furniture, and consumer goods. And though the nut measures less than half the height. A Jam nut is also included as a means of securing the Hex nut from self loosening. The wingnut is another type of nut with a smooth, flat and somewhat elongated top.

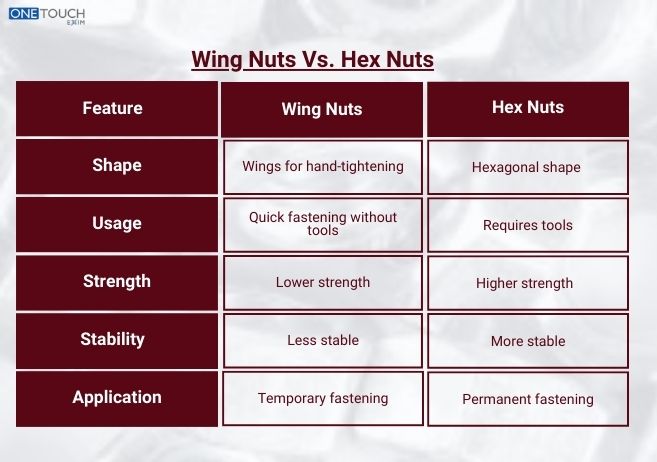

Difference Between Wing Nuts and Hex Nuts

The design and use are the main differences. Hex nuts hold in place against other objects when fastened and must be penetrated with a tool such as a wrench to be used and for this reason are sometimes called a “blind nut”. The protruding “wings” on wing nuts enable more manual installation and removal of every fastener without ever needing the use of wrenches, pliers or other tools. Used in applications where vibration or weight are a main concern, but provides less clamping force than a standard star knob. Who retains more strength, the hex nuts or wing nuts.

1. Overview

Hex Nuts : For the ultimate in permanent security. Their six sided construction permits high torque use with a wrench and they are vibrate resistant. They are critical in construction and engineering applications that need reliability and durability above all.

Wing Nuts : Finger tighten or use a wrench for more security and reach with adjustable tension without tools. Their two lateral “wings” allows for quick and easy installation and removal on any assembly that requires frequent access or disassembly (light, fixtures, furniture) where secure attachment is crucial but overall convenience can’t be sacrificed.

2. Functionality

Hex Nuts : Features high-torque design that prevents rounding out of nuts and bolts. They are the most common types of thumb screw as they are interchangeable, easy to install and reposition, durable and corrosion resistant.

Wing Nuts : For tool free hand tightening and quick adjustment. Their “wings” are designed to provide the grip needed for most applications and can be repositioned on the fastener and reused when not needed, or tools are convenient, at the expense of some shear strengthen; they should be used where high holding strength is not required.

3. Shape

Hex Nuts : They get their name to reference their six sided shape. This uniform crisp-edged firmly in the average tools. The symmetry lets torque be applied from any angle, evenly tightening down for secure installation. The internal bore is circular with threads to accommodate a bolt, providing geometric utility and mechanical effectiveness in high strength environments.

Wing Nuts : It looks fairly different from most other nut types on account of their two big, flat “wings” or plates that are often tapered coming out of a central threaded collar. These wings have enough surface area so that they can be gripped and turned by hand. It is a decagonal or round kurled cylinder the sides of which are cut away to form eight to twelve wings, which are longer than the body. This form gives up tool ability for a hand friendly design that primarily focuses on rapid, no tools change over than high mechanical force.

4. Installation

Hex Nuts : These nuts are intended for use with similar threaded machine bolts in applications that require more height and a larger bearing surface than would be achieved with a standard finished hex nut, so you can apply more torque without slipping. Correct fitting usually requires another tool in addition. This technique leads to a strong reliable fastening for structural, automotive or heavy duty applications where accuracy and safety are mandatory.

Wing Nuts : These nuts are made for easy, hand tool-free installation. The user grabs the two extended “wings” and turns them to tighten or loosen the nut by hand. It can be adjusted or dismantled without any tools when an application demands tool-less adjustments. But hand tightening reduces torque and clamping forces, so wingnuts aren’t suitable for instance of high stress, vibration or safety concerns. They care more about being nice than the long run.

5. Uses

Hex Nuts : Suitable for high-strength, permanent applications. They are used in construction, automotive assembly, machine parts and infrastructure where vibrations loosening is a concern. Their accuracy and dependability is ideal for its use in bolted structural connections engines, heavy equipment where accurate torque is needed and longevity is required.

Wing Nuts : These nuts are intended for frequent, tool-free adjustments. Also known as alligator-snap latches, these are widely used in consumer products such as light fixtures and furniture to secure doors and access panels. They are preferred when the mechanical design of the connection does not allow for much torque to be used or in designs that are hand-tightened.

6. Safety

Hex Nuts : These are very strong and when used with Hex Nuts provide maximum tensile strength, neither will strip or round of under high stress. Frequent visual check for full confidence of in-service use.

Wing Nuts : It should be noted that wing nuts are not capable of being used in high stress or mission-critical applications because they do not have a large torque and vibrational resistance. They might come loose too easily, which could be dangerous if the safety of something depends on being securely fastened. Limited to low-load, non hazardous uses.

Conclusion

A wing nut is designed to be tightened and loosened by hand, while a hex nut requires a wrench. Hex nuts are the most widely used type of nut and will work in most applications. Wing nuts are threaded nuts with wings on opposite sides of the body intended for manual turning. Strength and performance favor hex nuts, speed and accessibility favor wing nuts.