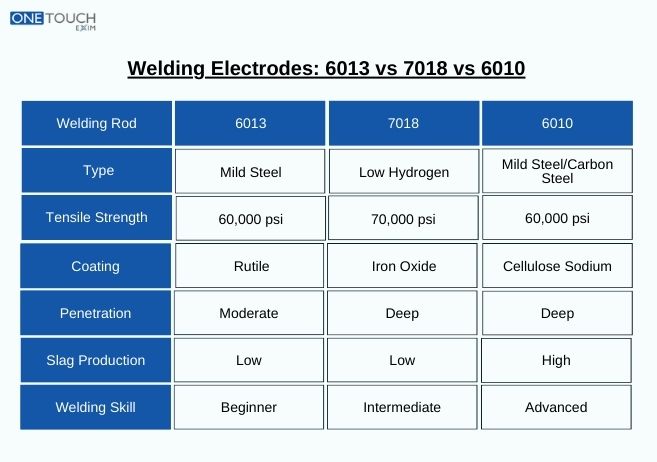

It’s a process of joining two metals with the use of heat and electric currents. Welding finds much application in aerospace, manufacturing, automobiles, to name a few. 6013 welding rods are the most common rods used for news users or even experienced users. This would be the best rod for light to medium penetration on metal sheets or thin metal pieces. 6013 welding rods are also known as “beginner rods,” “easy rods,” and “sheet metal rods.” The mild steel, rutile-based rods are good for a wide range of applications, including making truck frame bodies, metal furniture, storage tanks, and farm implements. 6013 welding rod uses extend to projects that need a smooth weld with minimal spatter, and they do reliably perform on thin to medium metal surfaces.

What Does E6013 Mean?

- E stands for the electrode.

- 60 determines the tensile strength, which means 60,000 pounds per inch.

- 1 shows the position of the electrode that can be used in all four directions: flat, horizontal, vertical, and overhead.

- 3 designates the flux composition, power supply, and slag. The 6013 welding rod can be used in AC or DC directly or for reverse polarity.

- E6013 welding rod uses include general welding on mild steel, auto repairs, and light fabrication, offering smooth, clean welds in all positions.

What Are 6013 Welding Rods Used For?

The special flux coating of the 6013 electrode contains ferromanganese, cellulose, rutile, potassium silicate as the binder, and added siliceous materials. This formulation allows operation in alternating current at lower amperages and with lower open-circuit voltages due to its active potassium element. The coating is also characterized by a very high percentage of titanium. The burning of the flux coating creates carbon dioxide, making the arc stable and quiet; the surface of the weld bead is smooth, with a consistent ripple profile. Any slag created can easily be taken out, and the 6013 welding rods can be used where there is poor joint fit-up. They are also great for multi-pass welds in which it is necessary to build up the weld by layering one pass at a time.

Applications & Properties Of 6013 Welding Rods

A person or a welder can Buy 6013 welding rods as it is used in various types of activities are as follows:

- General purpose fabrication

- Machine parts

- Metal Building and structures

- Shipbuilding and repair

- Thin sheet metal welding

- Shaft buildup

- Welding of vehicles

- Repairing excessively machined or damaged mild steel

Rutile-based Flux Coating

The flux coating on the 6013 welding rod is based on rutile. This kind of flux coating facilitates the production of a steady, smooth arc during welding and facilitates the removal of slag after the weld is finished. The rod’s user-friendliness is greatly enhanced by its rutile-based coating.

Shallow Weld Penetration

The shallow weld penetration of the 6013 rod is another crucial characteristic. This makes it ideal for joining sheet metal and thin materials together. For sensitive workpieces, the shallow penetration helps avoid burn-through. Because of this feature, the 6013 rod is a superb option for welding tasks requiring control and precision.

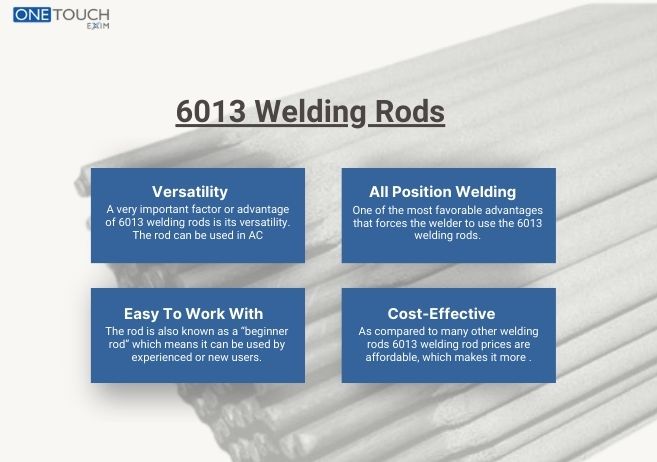

Benefits Of 6013 Welding Rods:

6013 welding rods become part of every industry. 6013 welding rods are the most important component used in every sector. Here are some benefits of 6013 welding rods are as follows:

Versatility :

A very important factor or advantage of 6013 welding rods is its versatility. 6013 rod use in AC or DC directly or for reverse polarity, making it compatible with welding machines.

All position welding :

One of the most favorable advantages that forces the welder to use the 6013 welding rods. It can be used in all four directions. It can easily be used in horizontally, vertically, overhead, or in a flat position.

Easy to work with:

The rod is also known as a “beginner rod” which means it can be used by experienced or new users. Due to its penetration, it has become more popular or common among the welders. The feature of self-peeling slag which means the slag can be easily removed after penetration is also the biggest common factor that makes it easier to use.

Cost-Effective:

As compared to many other welding rods 6013 welding rod prices are affordable, which makes it more popular among welders to use it. The cost-effective factor is a major advantage because a welder can buy a rod if it is affordable.

Amperage Or Diameter | 6013 Welding Rod Sizes

The diameter of an electrode must be selected or chosen by its amperage or current. 6013 welding rod comes in different diameters 2.5mm, 3.2mm, 4mm, and 5mm, each requiring different amperages (70, 100, 150, and 190, respectively). The diameter and amperage of the electrode must be chosen or selected depending on its base metal. It is important to adjust the size of amperage based on the electrode and base metal.

6011 vs 6013 Welding Rods

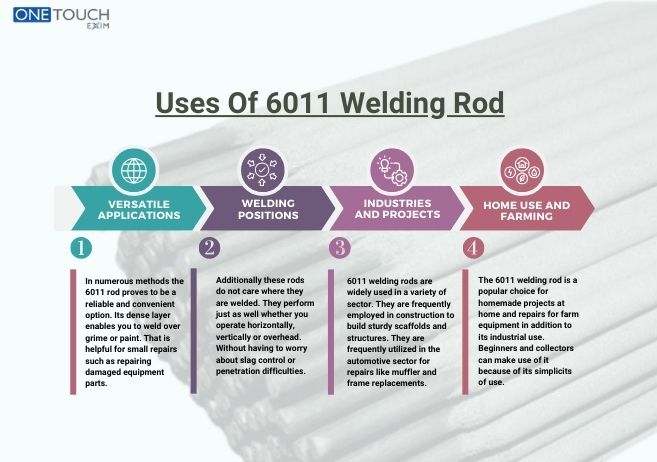

The selection of the right welding rod can vary the difference in the outcome of your welding project. Both 6011 welding rods sizes and 6013 Welding rods contain a difference between them.

6013 welding rod is known for its characteristic of creating a smooth inside root due to which it lets the welder move easily and quickly, it is also known as welder friendly..6011 welding rods work on AC and direct current electrode positive (DCEP), 6013 welding rods also work on direct current electrode positive (DCEP) and AC, it is the basic difference between 6011 and 6013 welding rods. 6011 welding rods are made up of a special alloy which resistant to heat and corrosion. It has a tiny nickel electrode and is made up of thin gauge wire.

Comparison Between 6013 And 7014 Welding Rods

The both 6013 and 7014 welding rods are similarities between them but there are some differences that are suitable for different applications. Both 6013 and 7014 are the properties of welding in all four directions flat, horizontal, vertical, and upward. The capability of doing welding in all directions makes it versatile for welders who need to work in all orientations. The 7014 welding rod is more useful or performs the work neatly and is more effective than the 6013 welding rod.

According to the appearance of the weld bead, the 6013 welding rod tends to produce a narrower and more controlled bead. It can be more beneficial if the welder wants a tidy, neat, and precise narrow weld on thin and visible joints whereas the 7014 welding rod on the other hand produces a broader bead, this wider bead can help to produce a broad gap and cover a larger area of welding.

Conclusion

6013 welding rod is the best choice for welders who want deep penetration and a stable arc. It is a great choice for experienced and new welders. It is a versatile electrode that has so many advantages of it. 6013 welding rod has a user-friendly design that helps the welder to do the work easily. The features of the 6013 welding rod make it a valuable asset in the welding world. A person or a welder can buy 6013 welding rods from trusted suppliers.