Stainless steel welding electrodes might not seem to be the most interesting topic in the world but let me tell you that they are a game changer. Electrodes are consumable components to create an electric arc between the electrode and the workpiece in welding. The heat created by the arc melts in the base metal which produces a welding connection along with the electrode. Stainless steel welding is performed using electrodes constructed of a specific type of stainless steel alloy. These electrodes contain a layer shielding the weld pool from outside gases and blocking oxide development, which can cause flaws in the weld. Stainless steel electrodes are long-lasting and require minimum maintenance. They are less expensive than carbon steel electrodes. Therefore, if you want to cut costs and enhance productivity, this is the best choice for you. However, they do not possess similar properties like carbon steels.

In this article we will talk about the uses and major advantages of SS Welding

Types of Welding Electrodes for Stainless Steel

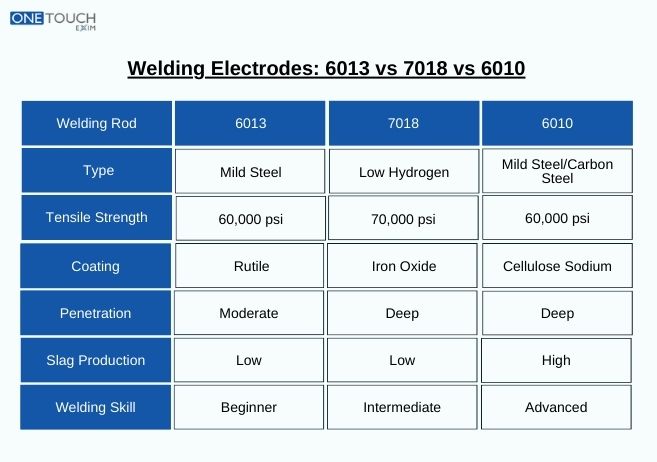

Different types of welding electrodes for stainless steel are classified according to their structure and coating.

The most common types are:

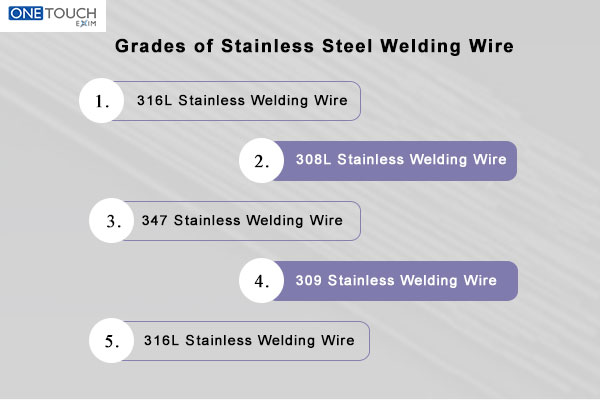

- E308L: it is a low-carbon electrode with high chromium and nickel content. It is suitable for welding stainless steels such as 304 and 304L.

- E309L: This electrode’s purpose is to recombine unlike metals like stainless steel with carbon or low-alloy steel. It carries higher carbon levels when compared to E308L, making it ideal for thicker welds.

- E316L: This electrode has a higher molybdenum content than E308L making it suitable for welding corrosion-resistant austenitic stainless steels such as 316 and 316L.

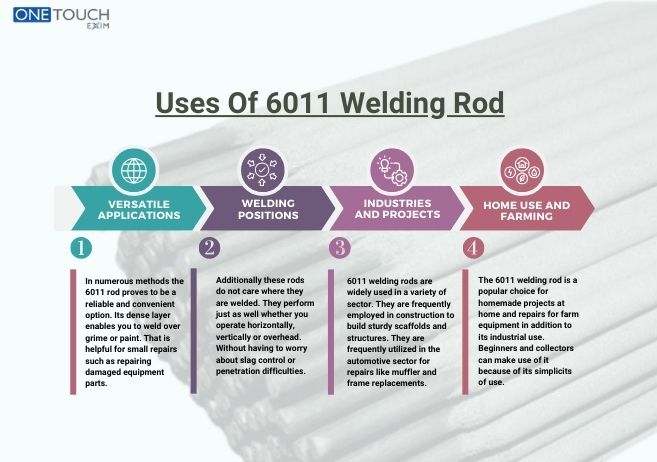

Uses of SS Welding Electrode

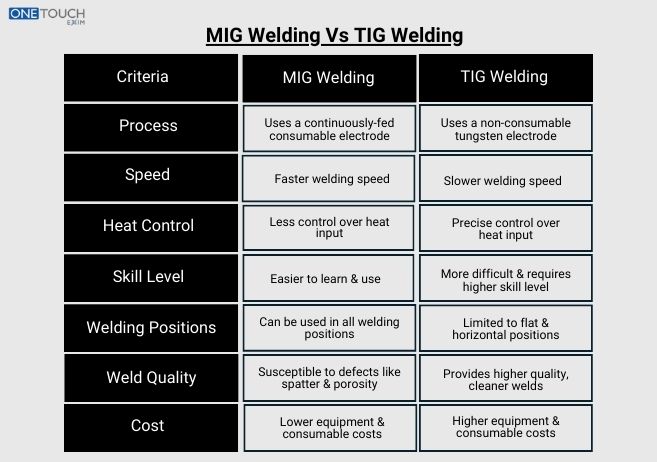

Other electrodes on the other hand can work with both. Determining the thickness of your base metal can help determine which electrode is suitable for the process. For example, thicker materials require electrodes with higher ductility and less hydrogen. Thin welding materials on the other hand require soft arc electrodes with smaller diameters. This ensures shallow penetration and helps prevent thin material from burning. Essentially you must understand your welding process before selecting the electrode. Your welding condition will affect the welding electrode you use.

In this case you should use the right type of filler metal. Stainless Steel welding rods are a good option for clad welding because they produce a better surface finish and microstructure than ordinary electrodes. Additionally they are more resistant to corrosion. That is why people can trust them more.

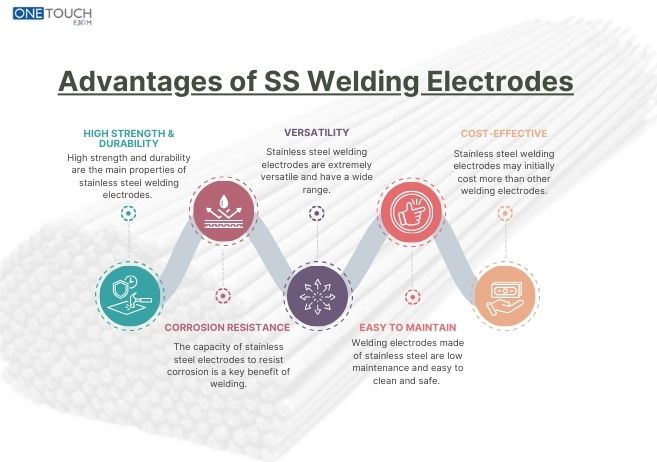

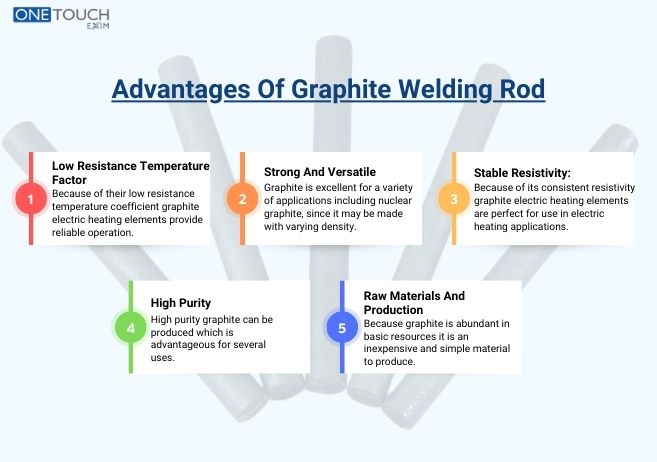

Advantages of SS Welding Electrodes

This magic wand is a small part of metal when held by an expert welder it can turn any simple steel sheet into a hardwearing and sophisticated structure that will withstand extreme conditions. However whether you are welding ship bridges for skyscrapers or pipelines with the best welding electrodes the bottom line is always about creating stable constructions that are strong enough. If you’re all set to explore more about the amazing world of stainless steel electrode welding then here are five advantages of using them:

High Strength And Durability:

High strength and durability are the main properties of stainless steel welding electrodes. This makes them perfect for building things that will be used in really bad weather.

Corrosion Resistance:

The capacity of stainless steel electrodes to resist corrosion is a key benefit of welding. It is ideal for shipyards and outdoor equipment because they are capable of being exposed to moist air that is high in vaporized water and other chemicals that cause rust.

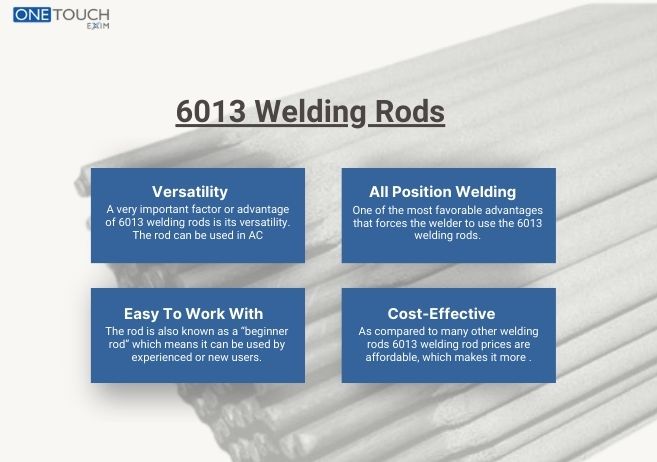

Versatility:

Stainless steel welding electrodes are extremely versatile and have a wide range of uses in the construction of airplanes and medical industries.

Easy To Maintain:

Welding electrodes made of stainless steel are low maintenance and easy to clean and safe. Because of this they are ideal for use in clean environments and industries like the food and beverage or medical fields.

Cost-Effective:

Stainless steel welding electrodes may initially cost more than other welding electrodes, but over time, they are cheaper to use because of their exceptional strength, durability, and resistance to corrosion. Compared to other materials, they last longer and require less care, which reduces the cost of replacement and repairs.

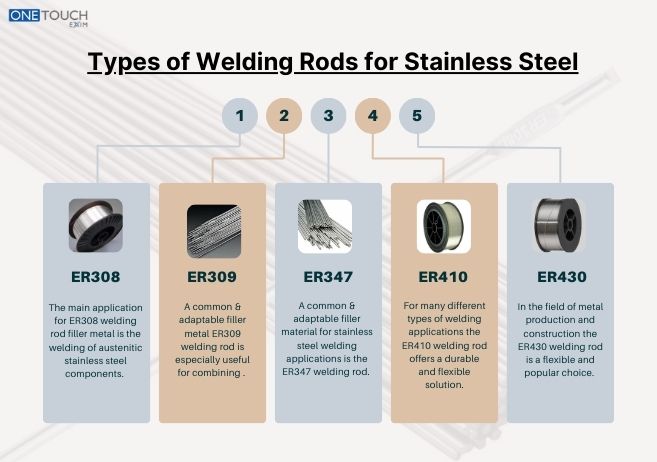

Welding Rod Used For Stainless Steel?

Commonly used stainless steel electrodes are usually designated as electrodes with a classification of E308 or ER308. These electrodes are fabricated in a unique way by technicians to weld stainless steel as they offer good resistance to corrosion and ease of welding. Their design is structured in such a way that it corresponds with the base metal structure in order to create strong and lasting joints. All these also have different sub types that include welding austenitic steel electrodes and welding ferritic steel electrodes which are both for special purposes only. So what needs to be done when choosing them?

Conclusion

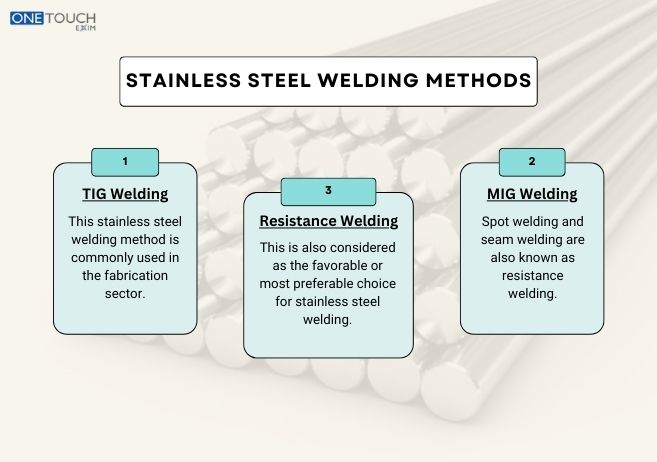

When Selecting electrodes for stainless steel welding choosing the correct electrode is important to achieve the best welding performance and quality. Factors such as base metal structural joint design and fit-up, and welding location are to be considered while selecting electrode type and size. In order to achieve the best welding results, it is important to thoroughly prepare the working metal and to avoid common defects.