Stick welding is the mainstay of many welding rod suppilers. Filler metals like AWS (American Welding Society) E7018 stick electrodes are a popular option since materials utilized for structural applications have remained conducive to the process throughout time. These stick electrodes have the low hydrogen levels required to avoid problems like cracking, as well as the chemical characteristics required for the applications. Additionally, they give the right mechanical qualities for these tasks; for example, filler metals with a tensile strength of 70,000 psi are needed for the majority of steel used in structural applications (A514). Stick electrodes E7018 satisfy such requirements and e7018 welding rod uses, include work in welding on low-alloy steels, pressure vessels, heavy machinery, and other structural parts where strong, crack-resistant joints are needed. Its versatility and reliability keep it a staple for professional welders.

7018 welding rod is a dependable and robust option for your future large-scale project. 7018 welding rod uses, amperage requirements, applications, optimal methods, and also 7018 welding rod specifications for utilizing all will be covered in this article. This welding rod’s strength and adaptability make it popular in sectors like construction and auto manufacturing.

What is 7018 Welding Rod?

Most high-electricity steels are welded using a 7018 welding rod, more commonly called a SMAW electrode. SMAW electrodes are covered electrodes because they have a flux coating on the outdoors of the electrode. This flux coating creates a slag that protects the weld from impurities in the air, helps to stabilize the arc, and increases the fluidity of the weld pool.

7018 welding rods are available in numerous sizes, ranging from 1/16 inch to 5/32 inch. The maximum 7018 welding rod amperage used depends on the diameter of the electrode. As a preferred guiding principle, one amp needs to be used for each 0.001 inch of electrode diameter.

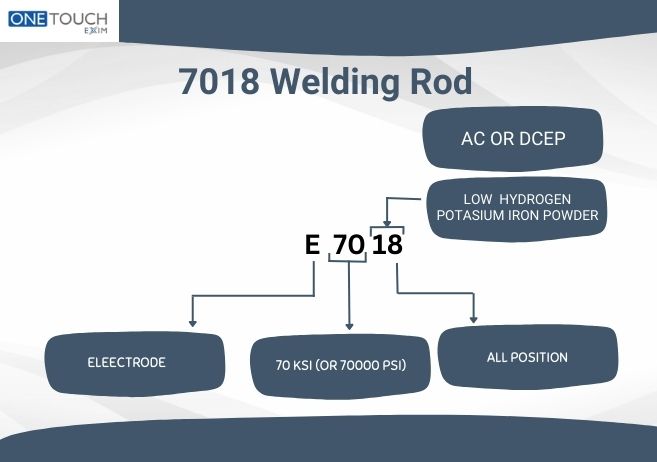

The code “E7018” of the stick welding electrode signifies its characteristics according to the American Welding Society standard:

“E” indicates that it is an electrode for shielded metal arc welding or stick welding process.

“70” denotes the minimum ultimate tensile strength of 70,000 psi. The minimum yield strength is 58,000 psi, and the elongation percentage is 22%.

“1” signifies that this electrode is suitable for welding in all positions, including horizontal, vertical, overhead, and flat positions.

“8” refers to the coating type, which is “Low-hydrogen potassium and iron powder.”It may be used with both DCEP (DC electrode tremendous) or DCRP (DC reverse polarity) and AC.

This occurs when the base metals are connected with the negative terminal of the power source and an electrode is connected to the positive terminal.

Features of 7018 Welding Rod

Welding can occur between materials made of the same kind of metal or between materials of different compositions. A wide variety of its features and tools exist to create stronger joints in buildings, bridges, and other wide-scale everyday applications:

All-position welding capability:

Suitable for flat, horizontal, vertical, and overhead welding, hence flexible for various programs, including shipbuilding, plumbing, and structural metal manufacturing.

Low hydrogen coating:

7018 welding rods have a low hydrogen coating and are less open to weld cracking. That is important in applications where there will be heavy tension or impact on the weld.

Easy to control, smooth, stable arc:

The 7018 welding rods make an arc that is far more stable and smooth. They are thus the best option for beginning and experienced welders also like.

Reduced spatter:

7018 welding rods create a little amount of splash, making clean-up easier and the rods less filthy after welding.The 7018 welding rods only splash a little, hence making the clean-up easier, and keeping the rods much cleaner after welding.

Outstanding bead look:

This provides welds with an easy and uniform look, making it appropriate for applications like architectural welding where aesthetics are crucial.

7018 Welding Rod: Its Properties

The 7018 welding rod is more flexible and gives a good look to productivity. It has many properties of 7018 welding rods which are:

High Tensile Strength:

The 7018 welding rod produces welds with excessive tensile strength, which refers to the ability of a material to resist pulling or stretching forces without breaking.

Good Ductility:

Ductility is the ability of a material to damage under stress. The 7018 welding rod has good ductility, so the welds are able to bend or twist without cracking or breaking.

Crack Resistance:

The 7018 welding rod is designed with a low hydrogen coating. The low hydrogen content of the 7018 rods minimizes the ability for such cracking, making sure of the integrity of the welds.

Toughness:

The 7018 welding rod presents exceptional toughness, which refers to the capability of a material to soak up power without fracturing. The high toughness of the 7018 rods ensures that the welds can withstand such conditions without failure.

Corrosion Resistance:

The welded steel produced with the aid of the 7018 rods exhibits good resistance to various forms of corrosion inclusive of atmospheric corrosion, moisture, and positive chemical compounds.

Properties make the 7018 welding rod famous for desire in big ranges of packages that include structural metallic materialation, pipeline construction, heavy equipment production, and diverse metal working tasks.

Calculating Amperage for 7018 Welding Electrode

Calculating the optimum amperage for the 7018 welding rod is important in achieving an awesome weld bead and steering clear of weld flaws. The amperage setting relies on the diameter of the electrode and the thickness of the material being welded. Here’s a manual on how to compute the amperage for the 7018 welding rod:

Determine the electrode diameter:

The diameter of the 7018 welding rod can range from 1/16 inch to 5/32 inch. Check the packaging or label of the electrode to decide its diameter.

Consult the producer’s suggestions:

Each producer provides a recommended ampere range for different electrode diameters. This variety is commonly printed on the packaging or available within the producer’s documentation.

Consider the material thickness:

The thickness of the material being welded also plays a position in determining the amperage. Thicker materials generally require higher amperage to make certain proper penetration.

Use a general guideline:

As a general guideline, for a 1/8-inch diameter electrode, an amperage setting of 125-170 amps is commonly used. For a 5/32-inch diameter electrode, an amperage setting of 185-250 amps is often used. However, it’s crucial to consult the manufacturer’s recommendations for particular amperage settings.

Adjust based on welding situations:

Factors such as joint configuration, welding role (flat, horizontal, vertical, or overhead), and preferred weld penetration can also require moderate changes to the amperage placement. Experienced welders fine-tune the amperage based on their specific requirements and welding conditions.

Practice and examine:

Practice welding with sample substances, using different amperage settings to determine the best aggregate of electrode diameter and amperage for the desired results. Observe the weld bead, quality, penetration, and overall weld integrity. Adjust as needed.

Remember, amperage setting is the key to a successful weld. Referring to the producer guidelines, taking into consideration the thickness of the material, and adjusting to the welding situation will determine the ideal amperage for the 7018 welding rod. Proper calculation and adjustment of amperage will help in getting an awesome weld bead with minimum spatter and weld flaws.

Uses for 7018 Welding Rod

The 7018 welding rod finds extensive use in various applications, including:

1. Shipbuilding: Resistant to corrosion and able to produce robust welds, making it suitable for the shipbuilding enterprise.

2. Bridge building: Widely utilized in welding bridge structural beams and components.

3. Structural welding: Ideal for welding structures requiring strength, durability, and crack resistance.

4. Automotive manufacturing: Used for welding car components including frames, chassis, and suspension sections.

5. Railroad maintenance: Utilized in welding railroad rails and infrastructure components.

6. Manufacturing of heavy machinery: Welding collectively heavy machinery components, which includes cranes, excavators, and bulldozers.

7. Boiler and pressure vessel welding: Provides robust and crack-resistant welds for boilers and pressure vessels.

8. Pipe welding: Widely used for welding pipelines, especially those with high temperatures and pressures.

Best Techniques for Using 7018 Welding Electrode

To achieve optimal results with the 7018 welding rod, follow these techniques:

1.Prepare the joint surface: Ensure the joint surface is clean and free from oil, grime, and rust.

2. Choose the best electrode diameter: Match the electrode diameter with the thickness of the material being welded.

3. Set the right amperage: Respect the ideal amperage variety based on the electrode diameter and material thickness.

4. Create a proper arc: Tap the electrode tip on the work surface, then swiftly remove it to create an arc.

5.Maintain consistent arc length: The electrode diameter and top-quality arc duration have to be almost the same, with a slight forward perspective.

6. Maintain a constant speed: Control the travel speed to save you excessive adherence or overly narrow weld beads.

7. Orient the electrode effectively: Angle the electrode slightly forward in the direction of travel.

8. Adjust the electrode: Manipulate the electrode to regulate the weld bead’s shape and penetration.

9. Remove slag: Use a chipping hammer and wire brush to remove slag after welding.

Additional Tips for Welding with 7018 Rod

1. Use a stringer bead method: A single, continuous weld bead is called a stringer bead. For butt and groove joints, stringer beads are usually utilized in the welding process.

2. The electrode is woven: One method for producing a wider weld bead is to weave the electrode. Usually, lap joints and fillet joints are welded using weaving.

3. Use a backing plate: A metal component called a backer plate is positioned behind the junction to support the pool of weld and stop burn-through. Usually, butt and fillet joints in thin materials are welded using backer plates.

4. Make use of a run-on and off tab: Short metal bits called run-on and run-off tabs are welded to the start and finish of the junction. To avoid the arc from beginning and ending on the base metal, which could result in weld flaws, run-on and run-off tabs are used.

Conclusion

The 7018 welding rod is a workhorse that one can put to use in a great number of structural welding jobs. With the proper technique, placing the amperage where you want can get you strong and sure welds. Be it in mild steel, stainless, or a variety of metals, the low hydrogen content material of the 7018 welding rod ensures quality work. Just remember to take all safety precautions with due attention to detail.