Stick welding electrodes, also called welding rods, are used in the Shielded Metal Arc Welding (SMAW) process. They include a metal core that dissolves and combines with the workpiece to create a weld. These electrodes have a coating of metal that releases shielding gas when heated, which helps to guard the weld pool from contaminants. One of the great advantages of stick welding electrodes is that they do not require an additional source of the metal core.

Stick welding, also called manual metal arc welding, offers several unique advantages. It is a flexible method that can be used to weld diverse metal alloys, together with Nickel, Aluminum, Copper, and Ferrous metals like Iron and Steel. Stick welding utilizes both direct current (DC) and alternating current (AC), with DC being the primary current type used in most applications. In this buying guide, we will explore the different types of stick-welding electrodes and provide valuable tips for selecting the right welding rod for your needs.

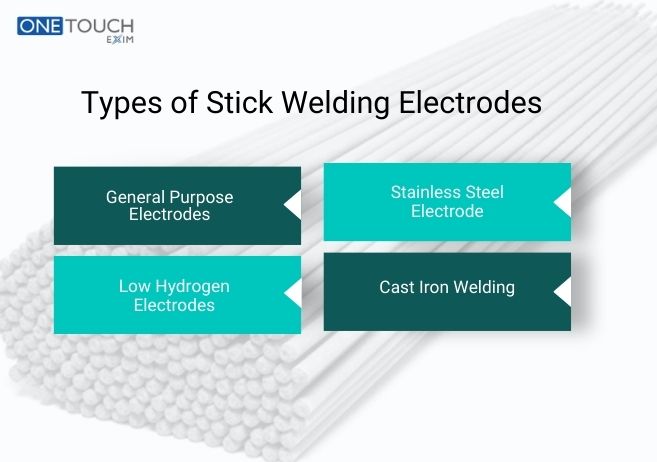

Types of Stick Welding Electrodes

Stick Welding Electrodes play a vital role in the welding process. They arrive in a diversity of scientific disciplines and sizes, and each one comes up with its particular purpose. There are several types of Stick welding electrodes, so it’s important to choose the right one for the particular task. Some general types of Stick-welding electrodes consist of the following:

General Purpose Electrodes – Commonly used for mild steel.

Example: (E6010, E6011 and E6013).

Low Hydrogen Electrodes – Primarily used for Carbon steel and low alloy steel welding.

Example: (E7018, E8018 and E10018).

Stainless Steel Electrode – Generally applied for stainless steel and high-quality metals.

Example: (E308L and E309I).

Cast Iron Welding – Fundamentally usable for cast iron and cast iron to carbon steel.

Example: (EniFe-CI and Eni).

Factors For Selecting The Right Stick Electrode

When deciding on a welding rod, several factors need to be considered, such as the type and thickness of the metal being welded, as well as the welding position. Here are some recommended welding rods that are considered to be the best in the market:

Forney 30405 E6013:

These versatile welding rods are appropriate for welding all sorts of moderate steel. They allow you to complete a project without changing rods.

Hobart 770460 6011:

These deep penetration welding rods are ideal for metals prone to rust and can handle contaminated jobs better than different electrodes.

Blue Demon 6013:

With a moderate price and a diameter of 3/32 inches, these welding rods provide adequate medium and shallow penetration.

US Forge Welding Electrode E6011:

These welding electrode rods are flexible and able to weld skinny metals while maintaining excellent track welding capacity.

Forney 30705 E7018:

These 3/32-inch welding rods can work on hardened and cold roll steel, providing a power capacity of 90 Amps.

Alumaloy Aim:

These rods are inexpensive and can be used to understand the working of s stick welding on ferrous metal and galvanized steel.

Buying Guide For Stick Welding Electrodes

Stick welding electrodes are used to create welds by means of melting and mixing with the workpiece. Here’s a brief buying guide for stick welding electrodes:

1. Types of Stick Welding Electrodes:

Stick welding electrodes come in various types, each suited for specific purposes. Common types include general-purpose electrodes, low hydrogen electrodes, stainless steel electrodes, and cast iron welding electrodes.

2. Consider the Metal and Welding Position:

When choosing a welding rod, consider the type and thickness of the metal you will be welding. Different electrodes have varying abilities for different metals. Additionally, recall the welding role (flat, horizontal, vertical, overhead) as a few electrodes are better suitable for certain positions.

3. Safety Precautions:

Always observe protection measures while the usage of stick welding electrodes. Use suitable protective gear, ensure an excellent electric connection, and be aware of ability dangers together with electric shock, arc rays, fumes, and sparks.

4. Current Type:

Stick welding rods can use alternating current (AC), Direct Current Electrode Positive (DCEP), or Direct Current Electrode Negative (DCEN). The current type you select depends on the welding requirements and the form of electrode you are using.

5. Size and Amperage:

Stick welding electrodes are available in different sizes, such as 3/32″, 1/8″, and 5/32″. The size you choose depends on the thickness of the material you’re welding. Additionally, recall the best amperage range for the electrode, which depends on its diameter and the thickness of the material.

6. Recommended Welding Rods:

Some famous welding rods in the market include Forney 30405 E6013, Hobart 770460 6011, Blue Demon 6013, US Forge Welding Electrode E6011, Forney 30705 E7018, and Alumaloy Aim. These rods are known for their versatility and performance in specific applications.

Following these recommendations will help you select the proper stick welding electrode for your welding needs and make certain successful welds.

Conclusion

Choosing the proper stick welding electrode is crucial for achieving high-quality welds. By thinking about elements along with electrode selection, protection measures, current type, size, and amperage, you can make an informed decision when purchasing stick welding electrodes. The comprehensive buying guide provided here, along with the recommended welding rods, will help you choose the most suitable electrode for your welding needs. Remember to consult with experts or talk to the manufacturer’s recommendations before making a final purchase decision.