In our blog of MIG welding guide welder gets the help while welding in a welding pool. In this process, the metal inert gas (MIG) welding runs high voltage through a consumable metal wire electrode to heat and fuse metals under a shielding inert gas. Because it is an efficient, quick, and straightforward method for consistently producing metal parts, it is significant to several sectors. MIG welding with wire feeds metal wire through a gun to melt and create a permanent joint. The welding wire manufacturer serves as the feed material for the weld as well as the electrode. This procedure is carried out while the molten metal is shielded from oxygen and other impurities by an inert atmosphere. MIG welding works well with thin metals and is simple to learn. It also doesn’t require any post-processing.

What Is A MIG Welding?

One of the several welding methods that use electricity to form joins is MIG welding. Since its invention in 1948, MIG weld has remained largely unchanged despite numerous equipment updates. There are different types of welding wire. Welding MIG, also known as flux-core arc welding, spray arc welding, gas metal arc welding, and short-circuit welding, is a type of gas metal arc welding (GMAW).

Who Is the MIG Welding Inventor?

In 1948, H.E. Kennedy created MIG welding in the United States. Since MIG welding creates an arc using a filler rod as an electrode, it is an improvement over previous welding methods. This was not like the earlier methods where the electrode would eventually wear out and need to be replaced.

How Does MIG Welding Differ From Laser Welding?

In MIG welding, metal parts are heated and fused by an electrical arc created by a high-voltage circuit and a continuously fed metal wire. An inert gas protects the arc in MIG welding. Instead, a laser is used in the laser welding process to heat and melt the metal to form a junction. Although MIG welding may put thicker metal together more quickly and precisely than laser welding, MIG welding produces a stronger weld.

What Is the Importance of MIG Welding in Manufacturing?

MIG welding is useful because it can combine heavy metal components quickly, produces a robust joint, and is efficient. MIG welding is likewise easy. Since MIG welding is simple, there is typically no scarcity of operators in the industry, regardless of expertise level.

What Is the Primary Purpose of MIG Welding?

Metal components are joined together via MIG welding. It is used to unite cast iron, aluminum, stainless steel, and steel. Sheet metal, pressure vessels, steel structures, pipelines, and automobile parts are all welded with MIG welding.

How does a wire feed welder work?

Setting up for MIG welding correctly is crucial. The general steps are listed below:

- Connect the ground wire to the welding table or workpiece.

- Set up the welding machine so that it can weld the metal.

- Wear the correct personal protective equipment (PPE).

- Securely fasten the parts that need to be welded together.

- Make tack welds on both joints’ ends.

- Use a pushing or pulling motion to fuse along the junction.

What Are Some MIG Welding Techniques?

The most crucial aspect of producing a solid weld is keeping your pistol in a suitable position and your hand steady. When welding, the gun’s tip should be no more than 3 4” from the metal to ensure that the weld pool is adequately covered with gas. For further stability, the gun should ideally be held in one hand and resting on the index finger of the other open hand. The welding gun should not tilt in the direction of one of the two metals when they are butted together. The gun should be angled 45 degrees towards the metal faces when the two metals are perpendicular. Finally, to get a feel for the proper movement, it helps to practice running the weld before actually welding.

What Are the Potential Influencers on MIG Welding Quality?

The most important variable that will affect the quality is the weld technique. Although the setup is important, it should be fine with the final weld as long as the wire feed rate, gas flow, and current are all nearly correct. Some of the most important variables are:

- Distance from the gun to the weld.

- The angle between the gun and the weld.

- Speed of the gun movement.

- Weld current.

- Wire feed rate.

- Gas flow rate.

- The removal of contaminants from the workpiece before welding.

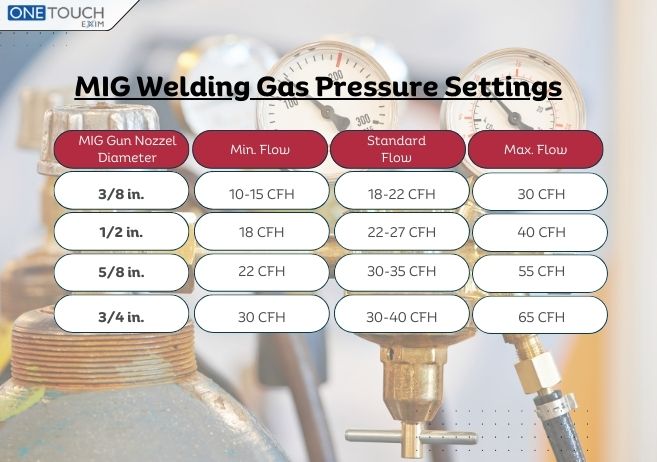

MIG Welding Gas Pressure Settings:

The table below summarizes the information to help you set the shielding gas flow rate depending on the welded material:

Shielding Gas | Material & required Shielding gas flow rate range | ||

| Mild Steel | Stainless Steel | Aluminum | |

| 100% CO2, 10% Argon, or 75/25 Ar/Co2 | 10-30 CFH | 20-25 CFH | – |

| Tri-Mix (10% Ar + 85-90% He + 2-5% Co2) | – | 25-40 CFH | – |

| 100% Argon | – | – | 25-30 CFH |

| Argon + 25%, 50%, or 75% Helium | – | – | 30-50 CFH |

Conclusion

MIG welds do make a spatter, and if you use a gasless wire with a flux core, some post-weld work needs to be done. Flux core wire supplier made wire for welding purposes. If you have used a flux wire, you’ll need to use a chipping hammer to take off the slag that formed its protective layer over the top of the weld. The majority of MIG welding requires a gas shield carbon dioxide and argon/CO2 mixes are the most common. To modify the gas flow, the gas bottle has a regulator or flowmeter. Although there are a lot of moving parts in this situation, using a gas flow of roughly 20 cubic feet per hour is a fair general guideline for light-duty welding. Once you’ve gotten some practice with the gun, you may try maximizing the gas consumption.