Welded wire fences, utility fences, and general-purpose fencing are all the same made up of spot welding electrical at the intersection of horizontal and vertical wires in the form of a mesh pattern. Rolled Mesh and Rigid Mesh are two formats of Welded wire fencing. One of the most popular welded wire fences is rigid mesh and is the first choice for works like construction, civil, etc. We have seen the welding wire manufacturers manufacture many designs of fencing. Let us also discuss how to cut welded wire fence. There is a very vast process of building a welding wire fence but on the other hand, its cutting process is easy. The best method of cutting welded wire depends upon the thickness of the wire and the tool you are using. Different fence-cutting tools are available in the market based on the thickness of the wire. For thinner wire use a wire cutter or tin snips and for thicker wire use a hacksaw, or angel grinder with the cutting wheel.

How to Cut Welded Wire Fence?

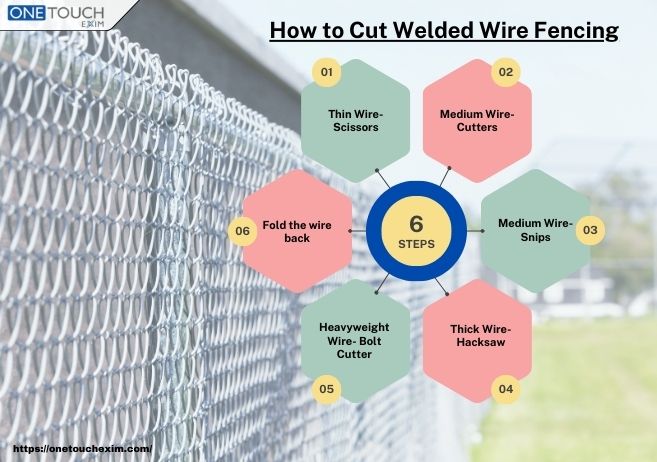

There are certain steps to follow while cutting welded wire based on the tool and thickness of the wire. Choosing the tool for wire cutting mainly depends upon the diameter of the wire that needs to be cut.

- Thin Wire Scissors– For thin wire up to 0.21 mm (35 gauge) use scissors. Cut every wire strand, particularly getting as close to the weld spot.

- Medium Wire Cutters– For medium wire up to 1.2 mm (18 gauge) use wire cutters. Cut every wire strand separately as close to the weld point. To avoid injuries while cutting pull away the detached part of the mesh.

- Medium Wire Snips– For medium wire up to 1.2 mm (18 gauge) use tin snips. If the wire looks tough to cut use tin snips instead of wire cutters because of their longer edge which helps in doing work quickly.

- Thick Wire Hacksaw– For medium wire up to 5 mm (6 gauge). Cutting stronger wire with a hacksaw is a longer process because each wire has to be cut individually.

- Heavyweight Wire Bolt Cutter– For medium wire up to 10 mm (0 gauge). This is the strongest wire mesh and can be shortened with the help of Bolt Cutter. This is a longer process because laying one of the arms of the bolt cutter on the ground placing the wire mesh between its sharp edges and pushing the other handle down with force.

- Fold the wire back– It is very important to fold the loose ends of the wire inwards so that they no longer poke out of the mesh to avoid injuries.

These are the certain steps to follow while cutting the welded wire fence based on their thickness different tools are suggested for cutting and one of the main things is to avoid injury by folding the wires inwards.

What is the purpose of Welded Wire Mesh?

The welded wire mesh is a cost-effective material and can be used for many purposes in daily life and different fields such as

- In domestic life, welded wire fencing can be used as safety covers for open and drain water areas, impact screens for windows, stairways, balustrading, shelving, fencing, cages, etc.

- Strength, endurance, and durability are the properties of weld wire that make it useful in the field of construction because wend wire reinforcement reduces the chances of improper bending and no space is needed for welding wire separately as it is easily available.

- Welded wire mesh is also used in agriculture to set physical barriers to keep animals away from farming land, and also used to construct poultry runs, aviaries, and livestock pens to secure animals’ environment.

- Wire mesh is also used in transportation and freight vehicles from warehouse areas to hospitals wire mesh cages and baskets placed on transport vehicles are popularly seen.

These are some of the places where welded wire is used on a large scale but if you see your surroundings you will after walking a few steps, there is use of welding wires. Some have been used in offices, some have been used in homes, etc

Safety Tips While Cutting Welding Wire Fence

Cutting wire mesh with the help of an angle grinder can be dangerous, so it’s necessary to take safety precautions. Here are some tips that are always in mind while cutting fences:

- Wear Protective Gear: Wear eye protection, ear protection, and a dust mask to protect yourself from debris, sparks, and dust. Wear gloves to protect your hands from the cutting disc.

- Keep the Work Place Clear: Clear the area around the wire mesh of any flammable materials, debris, or liquids. Keep bystanders away from the work area.

- Use Guard: The guard is designed to protect you from flying debris and sparks. Make sure it is adjusted correctly and use it at all times.

- Keep a Steady Hand: Keep a steady hand while using the angle grinder and avoid sudden movements or jerks. Use light pressure and let the cutting disc do the work.

- Allow the Disc to Cool: Cutting wire mesh generates heat, which can cause the cutting disc to wear out quickly. Allow the disc to cool periodically to extend its lifespan.

Conclusion

Electrically welding the intersection point of horizontal and vertical wire forms the welded wire fencing, Rigid wire mesh is commonly used in different in different industries, and these welded wires can be easily seen in homes for protecting gardens, securing windows, etc. We have also discussed the different tools for cutting welding wires such as scissors, cutters, tin snips, bolt cutters, etc these tools are used based on the thickness or diameter of the wire. Welding wire fencing is rigid and inflexible and damages under heavy pressure while woven wire fencing is ideal and good for livestock because of its ability to change without bending. Both types of fencing have their merits and demerits and can be used based on their needs.