Welding is a process of joining two materials with the help of weld, two things are more important in welding the first one is the rod and the second one is the base metal. Both play an important role in welding, the most important thing is to choose the welding. Today we will talk about the 7024 welding rod. 7024 welding rods is the finest rod for High deposition rate or flat or down-hand welding. This rod is made up of carbon steel and a thick iron powder coating, it is popular among welders because of its lightweight design and convex weld bead.

What Does E7024 Mean?

- E stands for the electrode.

- 70 determines the tensile strength which means 70,000 pounds per inch.

- 2 shows the position of the electrode that can be used in only two directions: flat and horizontal fillet welds.

- 4 designates the fast-fill, high-iron powder coating with a high deposition rate. The 7024 welding rod can be used in AC or DC directly or DCEN or DCEP.

What is the 7024 welding rod used for?

The 7024 welding rod consists of carbon steel and iron powder coating with a high deposition rate. This rod may not be as versatile as any other rod but it is useful for welding together the bigger pieces lying flat down on the floor because it has the properties of welding in horizontal and flat directions.

The 7024 welding rod price varies and is easily available in the shops, it is an affordable rod. The welder doesn’t need any other rod even using a 7024 welding rod. It is usually useful while working with steel. These properties made the electrode very strong, durable, and smooth for use. It can handle the weld in high-risk situations and pressure of structural welding.

Composition of 7024 welding rod

The welding rod is made up of many metals and many chemical compositions, like other rods 7024 welding rods are made up of containing many chemical compositions, that include carbon, Manganese, chromium, molybdenum, nickel, phosphorus, silicon, sulphur, and vanadium.

Amount of chemicals present:

- Manganese 1.25%

- Chromium 0.20%

- Molybdenum 0.30%

- Nickel 0.30%

- Phosphorus 0.35%

- Silicon 0.90%

- Sulphur 0.35%

- Vanadium 0.08%

7024 welding rod positions:

The rod is also known as a drag rod. As it is a lightweight rod, it can be used in only two directions flat or horizontal direction. The thickness of the rod decides or it may affect the amperage of the welding rod.

Applications of 7024 welding rod

The welding rod 7024 is used by welders in different kinds of areas and works. A welder can use the rod in welding the structures of vehicles, ships, boilers, welding in horizontal and flat surfaces, heavy sections of machinery components, heavy structural work like cranes and bridges, assembly of earthmoving equipment, welding heavy columns, locomotives, heavy machinery parts, building ships high pressure vessels, Repairing excessively machined or damaged mild steel, etc.

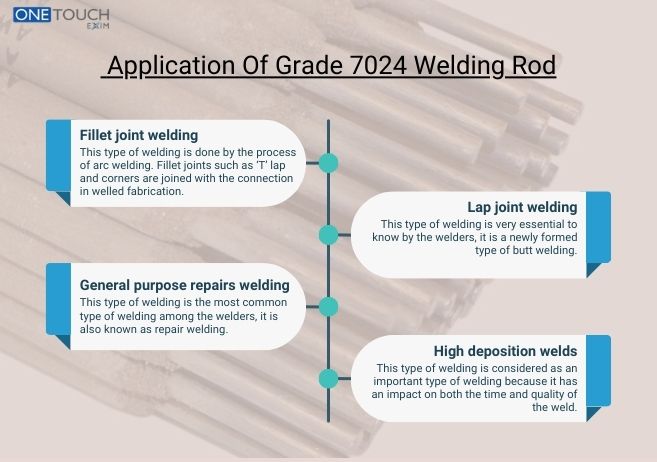

Types of welding | 7024 welding rods

Fillet joint welding:

This type of welding is done by the process of arc welding. Fillet joints such as ‘T’ lap and corners are joined with the connection in welled fabrication. It is the most common welding technique but also it is a difficult technique a new comer cannot perform this type of welding with visualization.

Lap joint welding:

This type of welding is very essential to know by the welders, it is a newly formed type of butt welding. Lap joint welding means welding the two different metals of different thicknesses on each other or overlapping two different metals.

General purpose repairs welding:

This type of welding is the most common type of welding among the welders, it is also known as repair welding. In this type of welding a welder should weld the crack side or join the crack side with other metal.

High deposition welds:

This type of welding is considered as an important type of welding because it has an impact on both the time and quality of the weld. The deposition rate should be measured by measuring how much material is deposited in a unit of time. It is usually expressed in either pounds per hour (lbs/h) or kilograms per hour (kg/h).

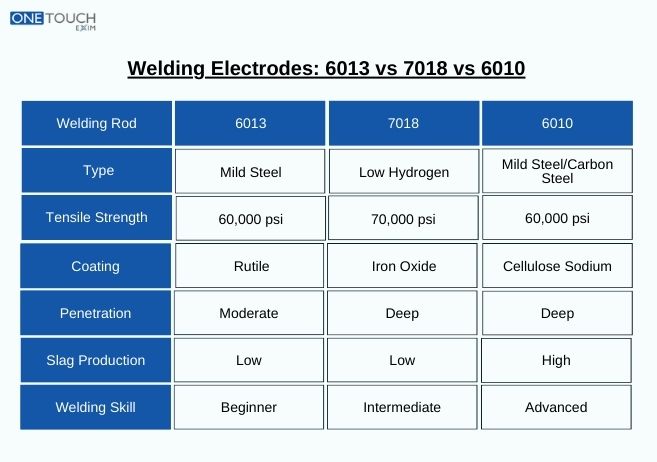

7024 Welding Rrod Amperage

It is most important to decide the amperage of the electrode according to the size or diameter of an electrode. with the help of an electrode, a welder should know or should decide the amperage and the base metal for welding. The amperage of 7024 welding rods according to their sizes are as follows:

| Diameter in MM | Volt | Amperage |

| 2.4 MM | 21-26 | 70-170 |

| 3.2 MM | 25-27 | 120-160 |

| 4.0 MM | 26-30 | 150-230 |

| 4.8 MM | 26-30 | 180-390 |

Uses of 7024 Welding rods:

The benefits of 7024 welding rods are as follows:

Polarity:

It can be used as straight or reverse polarity which means it can work on both AC and DC currents. The drag technique can be used in both AC and DC currents, which makes it compatible to work on both polarities.

Tensile Strength:

The number 70 in the code-named 7024 welding rod means the tensile strength of an electrode. It means it has a strength of 70000 psi ( pounds per inch ). These electrodes can handle or withstand high-pressure situations.

Penetration:

It has a tensile strength of 70000 psi but is used for low penetration, which means that it cannot burn far below the surface of the metal. While working with a 7024 rod welder should be more careful as it is used for the technique of shallow cuts.

Positionality:

One of the most common features of the 7024 rods is that makes it different from the other rods. The third digit ‘2’in the code 7024 stands for the positionality of the welding rod. It can work in the two directions flat or horizontal surfaces.

Conclusion

In the above text, we should learn about the 7024 Welding rod. The techniques which we can use with the rod. Areas where the rod should be used, benefits of the rods, on which amperage and volt should rod will work. If the welder is working on big steel projects, 7024 welding electrodes are good to have on hand for high deposition and fillet welding.