Stainless steel and aluminium electrodes differ greatly for stick welding.

Rods -243-7 Welding Consumables Stainless Steel rods are widely used and easy to weld. These electrodes are designed for welding various grades of stainless steel; they provide good strength and corrosion resistance. Stable arcs and easy slag removal.

Aluminium – Aluminium Rods are damn hard. They have a narrow process window reflecting aluminium’s oxide layer, high thermal conductivity and low melting point. Arc may wander, slag is difficult to remove and welds may have metal in them. These tend to be used only for a temporary emergency repair to non-structural aluminium parts tubes or even for structure.

You can’t stick weld aluminium, TIG or MIG are way better ways.

What is an Aluminum Stick Welding Rod?

Aluminium stick welding rods are special rods or electrodes used for welding aluminium using the conventional stick welder. They’re intended to eat through the tough oxide that aluminium forms, which melts at a much higher temperature than the raw material.

Yet they are widely known to be difficult to use effectively. The process is quite skill-intensive in order to control the arc and manipulate the molten electrode as it melts off. The result are usually contaminated by poor fusion, porosity and a dirty tenacious slag. As a result they are usually a last resort for non-critical fixes where a MIG or TIG welder – the correct tools for aluminium – isn’t an option.

What is a Stainless Steel Welding Rod?

Stainless Steel Welding rods are used during Shielded Metal Arc Welding (SMAW or “Stick” welding) of stainless steels. The core wire in the electrode is an alloy of the SS material (e.g. 308 or 304 Stainless), which adds the required corrosion and strength factors to the filler metal.

The flux provides stability to the arc, protects the molten weld from oxygen in the atmosphere, and helps form the slag covering. These rods have excellent arc control and are ideal for use in the field, repair, and where the utmost in mobility is required. They tend to be much easier to use than aluminium sticks but you need some skill to avoid flaws.

The Role of Welding in Modern Manufacturing

Welding is a bedrock of manufacturing and is one of the only ways to permanently bond materials together to form a complex, structural whole. It is essential material in the automobile, aerospace, construction and energy industries.

It delivers unmatched strength and stability in the joint, light weight and low maintenance. As for the former, progress in concepts such as automation, robotics, laser welding, friction stir welding processes have significantly resulted in improvements in precision, efficiency and repeatability.

Welding allows for creativity which makes everything from prototype to mass produced consumer goods possible. It’s an enabling technology that drives creation of micro-electronics through to skyscrapers and ships.

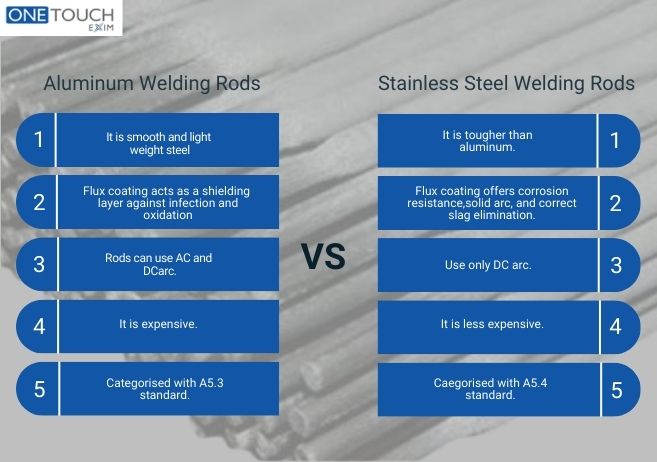

Differentiate the Aluminum vs Stainless Steel Stick Welding Rods

Aluminium Stick Welding rods (i.e. 4043) stick out like a sore thumb. Meant for emergency welding, they labour under the oxide-rich layer of aluminium, resulting in arcs that are unstable while also suffering from porosity and a sticky and tenacious slag. They are higher expert, not ready for prime time.

Stainless Steel Stick welding electrodes are frequently used and easy to use. They meet exacting industry standards, including AWS A5.2 and AWS A5.8 and offer excellent puddle control, clean arc transfer with minimal spatter, great arc direction and easy slag removal. They are a convenient, portable answer for all around welding on building projects, home repairs, maintenance and fabrication welding.

The Challenges of Welding Aluminum and Steel

Welding of Aluminium is difficult because it is covered with a tenacious exide film that melts at approx 2000 degree celsius which is much higher than the melting point of the base metal, the high thermal conductivity, the low melting point and high coefficient of thermal expansion which leads to the development of large and persistent high temperatures weld distortion and burn through. It is susceptible to hydrogen assisted porosity.

Problems in welding steel relate to adjusting the alloy content of the carbon to avoid creation of brittle microstructure and cracking in the case of high carbon or alloy grades. The role of preheating and a close control on the heat input is usually crucial. It is simply much too touchy to do properly against stainless to prevent carbide and corrosion. Both require skills, but the underlying challenges differ.

Choosing the Right Welding Process for Aluminum and Steel

Selecting the proper welding process for aluminum and steel is based on basic material characteristics as well as application requirements. Aluminum needs TIG (GTAW) or MIG (GMAW) welding, because they allow a higher control of what is happening, no contamination and properly managing its very high thermal conductivity. Of the various methods—Stick (SMAW), MIG, or TIG—MIG is fast but TIG is precise and makes cleaner welds. When aluminum and steel require joining, specialized methods, such as the use of bimetallic transition inserts or explosion welding, are employed since direct fusion is impossible. Choosing the proper method ensures strength, solidity and quality with minimal burn-through or other defects in the weld.

Conclusion

In summary, aluminum and stainless steel stick welding rods can be selected according to project needs. Aluminum rods are well-suited for lighter-weight, corrosion-resistant applications, but require skill and precision to stack. Stainless steel is used for corrosion- and heat-resistant applications, such as welding and heating appliance components. Each has its unique benefits, and understanding the ideal application of both helps welders produce dependable, high-quality results with efficiency and performance that deliver solid weld integrity for use in a variety of environments.