When it comes to welding, the choice of aluminum vs stainless steel stick welding rods plays an essential role in determining the success or failure of the project. Among the various kinds of rods available the most popular are the aluminum stick welding rod and the stainless steel welding rod. These rods are designed for special purposes, and in this article, we explore more about the stated welding rods that help you opt for the suitable one.

What is an Aluminum Stick Welding Rods?

An aluminum stick welding rod is a filler rod made from aluminum alloy that is particularly designed for aluminum welding. It consists of a flux coating and a core aluminum wire. Welding experts use aluminum stick welding rods with unique expertise to obtain the expected results in their work. In the welding process following rods are used to define the hints and specs for aluminum alloy and pure aluminum electrodes i.e. Shielded Metal Arc Welding (SMAW), and American Welding Society (AWS).

What is a Stainless Steel Welding Rod?

Stainless steel stick welding rods provide filler steel for welding chrome steel and different well-matched metals in SMAW (shielded metallic arc welding) obligations. These welding rods have a coating that releases protective fuel because it’s heated, which facilitates keeping contaminants out of the weld pool.

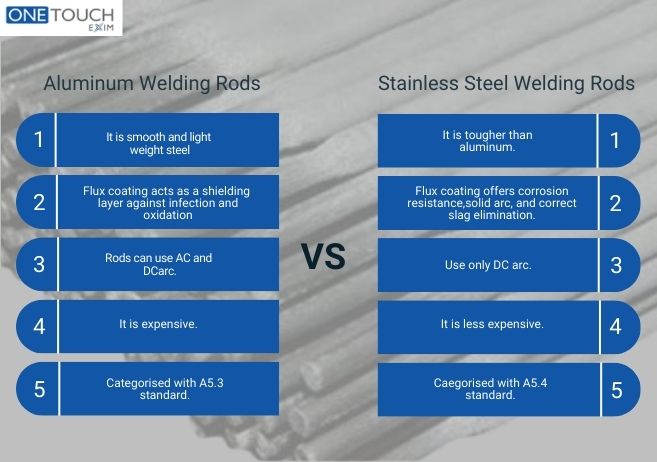

Differentiate the Aluminum vs Stainless Steel Stick Welding Rods

Both rods are used for welding purposes but there are some differences between them according to their usage, characteristics, cost, etc. Understanding the differences will help you make the right choice are:

1. On the Basis of Characteristics

The primary cause of the aluminum stick welding rod is to weld aluminum. Aluminum is a smooth and lightweight steel with high thermal conductivity. The aluminum stick welding rod is mainly designed to work with these properties of aluminum.

On the other hand, stainless steel welding rods are used to weld stainless steel, which has different properties than aluminum. Stainless metal has lower thermal conductivity and is tougher than aluminum. The characteristics of stainless steel make it suitable for working with stainless steel materials.

2. On the Basis of Coating

Both aluminum stick welding rods and stainless steel welding rods use a coating called flux coating. Flux coating acts as a cleansing agent, flowing agent, and purifying agent at some point in the welding process. However, the motive of the flux coating differs for every type of rod.

For aluminum stick welding rods, the flux coating acts as a shielding layer against infection and oxidation. In the case of stainless steel welding rods, the flux coating offers corrosion resistance, solid arc, and correct slag elimination.

3. On the Basis of Polarity

Aluminum stick welding rods can use both DC and AC opposite polarity mechanisms, which produce a gentle arc with low penetration impact.

On the other hand, stainless steel welding rods use only DC opposite polarity, which produces medium to deep penetration.

4. On the Basis of Cost

The cost of aluminum stick welding rods is typically higher than that of stainless steel welding rods because of their rarity and restrained availability.

Stainless steel, however, is simply available in large portions for welding purposes, making stainless-steel welding rods less expensive and extensively accessible.

5. On the Basis of Classification

The classification system defined by the AWS is critical in determining the mechanical residences and welding parameters for special types of welds. Aluminum stick welding rods are categorized in line with the A5.3 standard.

Stainless steel welding rods are classified according to the A5.4 specification.

6. On the Basis of Welding Process

Aluminum stick welding rods are normally used for SMAW and are best for horizontal and flat welding positions. The specialized flux coating utilized in aluminum stick welding rods helps with arc stabilization and stops porosity in the weld.

Stainless metal welding rods can be used for various welding processes, consisting of Gas Tungsten Arc Welding (GTAW), Shielded Metal Arc Welding (SMAW), and Gas Metal Arc Welding (GMAW). They are appropriate for maximum welding positions.

7. On the Basis of Deposition Rate

The deposition rate of aluminum stick welding rods is slower than stainless steel welding rods. The layer of aluminum oxide formed at some point of atmospheric exposure hinders fusion between the base metal and the weld metal, resulting in a slower deposition price.

Stainless steel welding rods have a higher deposition price because of their good thermal conductivity. The heat emitted from the arc is quickly transferred, making an allowance for a better deposition rate. Additionally, the diameter of stainless steel welding rods is greater than that of aluminum stick welding rods, allowing more filler to be deposited in a shorter time.

8. On the Basis of Welding Position

Stainless metal welding rods provide greater flexibility in phrases of welding positions. They can be used for nearly all types of welding positions and are more immune to cracks and lines. This versatility makes stainless steel welding rods suitable for complex projects.

Aluminum stick welding rods are commonly used for horizontal and flat positions. Aluminum, being soft and ductile, may not be best for complicated tasks that require greater robust welds.

9. On the Basis of Mechanical Properties

Aluminum stick welding rods, alternatively, provide excellent ductility and are frequently used in applications where weight is a critical factor. Aluminum welds are lightweight and have superb thermal conductivity, making them suitable for applications in industries including aerospace and automotive.

Stainless steel welding rods usually provide better yield strength and tensile strength compared to aluminum stick welding rods. Stainless steel welds are acknowledged for their durability, corrosion resistance, and high power. The mechanical properties of stainless steel make it appropriate for applications that require robust and long-lasting welds.

Conclusion

In conclusion, aluminum stick welding rods and stainless steel welding rods have different characteristics and are designed for particular functions. The choice among the two depends on the material being welded, the welding process, and the preferred properties of the final weld.

If you are operating with aluminum and require welds with desirable thermal conductivity and low weight, aluminum stick welding rods are the best choice. On the other hand, if you are operating with stainless steel that requires corrosion resistance, high electricity, and durability, stainless steel welding rods are the better choice.

It’s essential to keep in mind factors inclusive of cost, availability, welding position, and mechanical properties while choosing between these two forms of welding rods. Consulting with welding professionals or referring to the specifications provided by AWS can further assist in making the right choice for your particular welding project.