AWS A5018 VS A5.20 are the requirements for carbon steel and low alloy steel electrodes and rods for gas shielded arc welding. A5.18 specifies electrodes used for GMAW and FCAW and details and their ER70S-X classification for mild steel and options for increased mechanical properties. A5.20 deals with electrodes for gas shielded arc welding of low alloy steels with corresponding classification e.g. ER80S-X and ER90S-X, which are suitable for higher strength and toughness levels. While A5.18 is recommended for general purpose welding of carbon steels, A5.20 applicable to low alloy steels for service in more challenging environments. These two specifications maintain consistent chemical composition, mechanical properties and actual usabilities with the former showing slightly higher real characteristics although A5.20 receives chromium, nickel alloys for strengthening and corrosion resistance.

Key Features of A5.18 Standard

The AWS A5.18 standards cover the carbon steel electrodes and rods and gas metal arc welding and gas shielded flux cored arc welding processes. It categorizes welding filler 2.70n metals, such as ER70S-X, which are based upon tensile strength and yield strength. The filler metal needs to meet mechanical properties of deposited weld metal as specified. The chemical composition limits to control weld metal integrity and to minimize flaws are specified in the standard. Electrodes may contain deoxidizers for better arc stability and less porosity. A 5.18 will work with C02 or argon CO2, shielded gases are an excellent choice for welding mild and low alloy steels in structural, automotive and general fabrication even circulation fans. The specification guarantees uniform performance, weldability and strength when yield and tensile are described according to the requirements.

Key Features of A5.20 Standard

The AWS A5.20 covers carbon steel electrodes for gas shielded, flux-cored arc welding to ensure high quality welds which meet demands of structural and general applications. Examples of such classification are E70T-X and E71T-X where numbers of 70 or 71 are the minimal tensile strength in 70 ksi or 71 ksi respectively. The standard includes self shielded and gas shielded wires for all position welding. Flux cored wires offers slag pick up, deoxidizers and arc stabilizing agent, which reduce porosity and provide weld ability. A5.20 electrodes are intended for single or multiple pass welding on mild and low alloy steels having superior mechanical properties and impact resistance. It provides sustained performance, ease of application and contains a variety of modifiers for ensuring the compliance with strength, ductility and peace of mind of crack resistance.

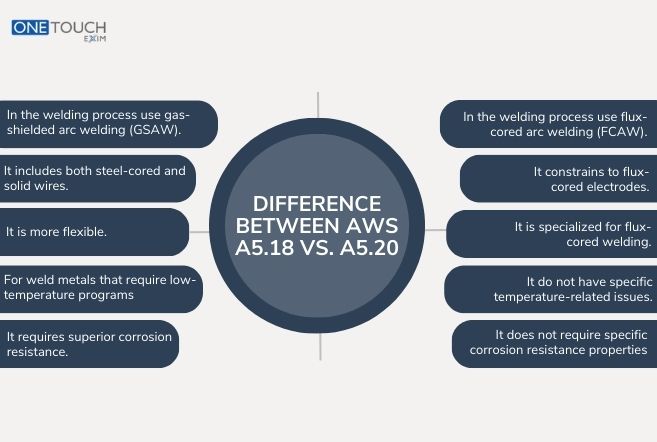

Differences Between Aws A5.18 vs. A5.20

The AWS A5.18 and A5.20 regulations vary in terms of their breadth applications. A5.18 relates to solid and composite carbon steel wires for GMAW and gas shielded FCAW and ER70S-X. In highlight, A5.20 requires flux cored electrodes which include gas shielded and self shielded types, such as E70T-X and E71T-X, which provide higher deposition rate and have slag systems from which it is easier to remove the slag to provide higher quality welds. While A5.18 is for clean , sharp welds, A5.20 is best for outdoor or wind conditions and heavy fabrications. A5.20 also is for all position welding but A5.18 is sometimes confined to selectively different procedures and settings. Both provide strength and ductility, but address different welding requirements.

Uses and Applications of A5.18

The AWS A5.18 code is frequently used in applications where high quality is required on carbon steel. Its ER70S-X series electrodes are great for gas metal arc welding and gas shielded flux cored welding, super pretty bead, less spatter, stable arc. Typical uses are structural steel fabrication, automotive manufacturing, ship building and pipeline construction and the need for a high strength oil usable steel, and good ductility are critical. These products work with CO2 and are suitable for use with argon/CO2 , mixtures for welding in all positions. A 5.18 electrode is also utilized in general construction, pressure vessel construction and machinery repair, because of its crack resistance. With their low sulfur and low phosphorus content, these materials are ideal for crucial welds that demand reliability and performance.

Uses and Applications of A5.20

The AWS A5.20 is intended for flux cored arc welding of carbon and low alloy steels, and is available in a wide range of wires. A versatile one wire that works for heavy and light duty welding, both indoors and outdoors. Being EXXT-X class they offer high deposition rates and deep penetration – well suited to heavy fabrication, structural steelwork, shipbuilding, and bridge construction. Self shielded types create their own shielding gases and can be used in outdoor settings where gas shielding is not possible. These rods are popular in applications such as pipe welding, offshore platforms, and general maintenance which require all position welding. A5.20 slag control, crack resistance and impact toughness and an overall improvement. 20 wires are ideal for high strength, high volume, welding application in rough environments and deliver a clean weld even on dirty or rusty material.

Conclusion

The AWS A5.18 and A5.20 standards, play different but linked functions to figure, out the welded joint. A5.18 is designed for GMAW and gas-shielded FCAW, and is ideal for welding carbon steel, with the arc stability providing low spatter. Great for automotive, structural and precision fabrication. In highlight, A5.20 is centered on flux cored electrodes and provides excellent deposition and all position capabilities, as well as extreme performance in severe conditions, serving to be a leading option to heavy construction, shipbuilding and field welding. While A5.20 offers flexibility with a self shielded option for outdoor application. Which one of them to go for depend on weld process, material specifications, and environmental factors but they both will give strong and reliable welds if used appropriately.