Super solid stainless steel includes alloys like Incoloy. Incoloy 800 vs Inconel 800 alloys contain silicon, molybdenum, copper, nitrogen, and nitrogen additives in addition to the base metals nickel, chromium, and iron. These alloys are well known for their excellent corrosion resistance in a variety of harsh environments and for being extremely durable at high temperatures.

Incoloy alloy 800 is a nickel, iron, and chromium alloy. The alloy’s stability and austenitic structure can be preserved even after long exposure to high temperatures. In addition, the alloy exhibits outstanding strength and a robust resistance against oxidation, reduction, and moisture. The following forms of this alloy are frequently available: wire, strip, plate, round, flats, forging stock, tube, and plate.

Inconel-800 is a member of a large class of nickel-based superalloys that are used in a variety of specialized aerospace applications, especially on turbines and aero components. This material is used in this field because of its many good qualities, such as its strong physical and chemical resistance to high temperatures and its ability to survive corrosion. However, this alloy falls into the high susceptibility category and its machineability shouldn’t be considered because of a few intrinsic properties like extremely high toughness, a low heat transfer factor, and limited work hardening.

Difference b/w Incoloy 800 vs Inconel 800

- Within the same superalloy family are the alloys known as Inconel and Incoloy, which are frequently called high-performance alloys. Both superalloys have excellent resistance to oxidation in addition to having a high level of resistance to different types of corrosion.

- Nickel and chromium make up the majority of the chemical composition of the alloy Inconel 800. This alloy’s chemistry usually contains more than 50% nickel. On the other hand, the main constituents of the alloy Incoloy 800 are iron, nickel, and chromium.

- Inconel 800 forms a thick stable oxide layer at high temperatures. It is well known that this thick layer shields the Inconel 800 component’s exterior from additional damage. A reasonable choice is Incoloy 800 alloy, which is regarded as the perfect material for applications involving high temperatures. Applications for this alloy are generally less demanding even though it is used at a higher temperature.

- The nickel-iron-chromium alloy found in Inconel 800 exhibits good strength as well as outstanding resistance to corrosion and oxidation in environments with high temperatures. Because of its resistance to stress cracking, Incoloy 800 has also been employed in certain steam generation plants and is corrosion-resistant in a variety of aqueous environments.

- Because it can endure sour gas and high chloride environments, Incoloy 800 is a popular choice in the oil and gas industries. Thanks to its exceptional strength and stiffness. Inconel 800 is a perfect alloy for demanding applications such as those in the chemical processing, aerospace, and marine engineering sectors.

Features of the Incoloy 800

There are some features of the Incoloy 800 given below:

- The exceptional strength of creep rupture.

- It has high-temperature power.

- It has an exceptional ability to resist corrosion in an acidic atmosphere.

- Extremely strong in sulfur-containing environments.

- Tolerance to carburization and oxidation at high temperatures in the atmosphere.

The chemical composition of Incoloy 800 vs Inconel 800 is given in the following table:-

| Element | Content% in Inconel 800 | Content% in Incoloy 800 |

|---|---|---|

| Iron | ≥39.5 | ≥39.5 |

| Nickel | 30-35 | 30-35 |

| Chromium | 19-23 | 19-23 |

| Manganese | ≤1.5 | ≤1.5 |

| Other | Rest | Rest |

Similar in basic composition to Incoloy 800, Incoloy 800 H is an iron, nickel, and chromium alloy.

The mechanical properties of Incoloy 800 are written below:-

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 600 mpa | 87 ksi |

| Yield strength | 275mpa | 39.9 ksi |

| Elongation at Break | 45% | 45% |

The mechanical properties of Inconel 800 are written below:-

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 550 mpa | 87 ksi |

| Yield strength | 205 mpa | 39.9 ksi |

| Elongation at Break | 30% | 45% |

The physical properties of Inconel 800 and Incoloy 800 are written below.

| Properties | Metric (Inconel800) | Metric (Incoloy 800) |

|---|---|---|

| Density | 0.287 lb/in³ | 0.287 lb/in3 |

| Melting Point | Around 2400-2550°F | 1425 °C |

| Specific heat capacity | 0.107 J/gK to 0.110 J/gK. | 460 J/kg·°C |

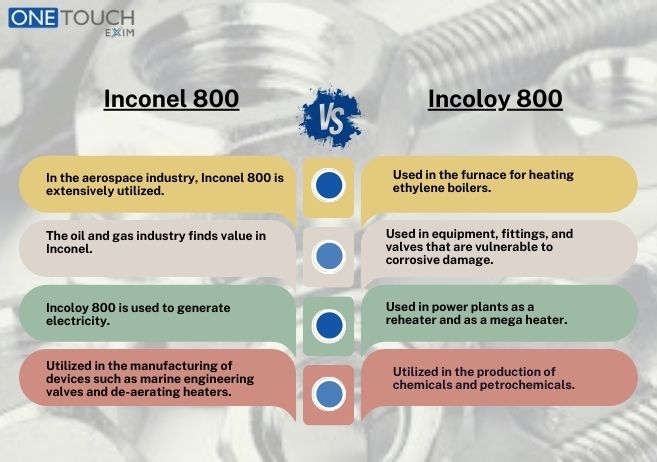

Uses of Inconel 800 and Incoloy 800 alloy

| Uses of Inconel 800 alloy | Uses of Incoloy 800 alloy |

|---|---|

| In the aerospace industry, Inconel 800 is extensively utilized, especially in jet engines. | Used in the furnace for heating ethylene boilers. |

| The oil and gas industry finds value in Inconel due to its resistance to corrosion at high temperatures. | Used in equipment, fittings, and valves that are vulnerable to corrosive damage. |

| Incoloy 800 is used to generate electricity. | Used in power plants as a reheater and as a mega heater. |

| Utilized in the manufacturing of devices such as marine engineering valves and de-aerating heaters. | Utilized in the production of chemicals and petrochemicals. |

Price structure of Inconel 800 and Incoloy 800

- Inconel 800

High-performance nickel-iron-chromium alloy Inconel 800 can have different prices depending on the supplier, form (sheet, plate, round bars, etc.), and quantity.

- The cost of 800 Rectangular Inconel sheets is ₹1,009 per kilogram.

- An Inconel 800-thickness sheet (2–10 mm)The cost is 10,000 ₹ per kg.

- The cost of an Inconel 800 HT sheet is ₹1,750 per kg.

Note: Prices may vary according to the market value.

- Incoloy800

In India, a kilogram of Incoloy 800 costs roughly ₹1200. It’s important to remember, though, that costs can differ significantly depending on several factors, such as supplier, location, and market circumstances.

- Incoloy 800 costs roughly ₹1400 per kilogram in Japan.

- The price per kilogram could range from roughly ₹1500 in the UK and Europe.

- The price per kilogram could be roughly ₹1600 in the USA.

Use of Inconel 800 alloy in Aerospace/Automotive

There are some uses of Inconel 800 alloy in Aerospace/Automotive given below:

- Eight Inconel earrings in total supported the weight of the ready-to-fly Shuttle system, with four being used to secure the solid rocket boosters to the launch platform.

- Inconel X/750 alloy was used by North American Aviation to build the skin of their North American X-15 rocket-powered aircraft.

- The turbine wheel in the turbocharger of Ford Motor Company’s EcoBlue diesel engines, which were first introduced in 2016, is made of Inconel.

- Since then, BMW has employed Inconel to withstand higher temperatures and lower backpressure in the exhaust system of its high-performance luxury vehicle, the BMW M5 E34 with the S38 engine.

Conclusion

Incoloy 800 and Inconel 800 are both superalloys known for their excellent corrosion resistance and durability at high temperatures. Inconel 800 is commonly used in aerospace applications, while Incoloy 800 is popular in the oil and gas industries. Both alloys have different chemical compositions and mechanical properties, but they share similar uses in power plants, chemical production, and marine engineering.