Do you demand steel tubing for your next assignment? Are you uneasy about how strong the individual type of steel tube is? Need to get a more reasonable opinion of which kind of tube to utilize? If we replied yes to these questions, you’re in luck because we’ve put together a guide planned to answer the query, “How strong is square tubing?”

As we read via this directory, you’ll understand which type of steel tubing is most powerful. You’ll also find out the advantages and uses of square tubing. We need to learn that we have the right steel tube for what we require to do. We also want to be certain it can keep up with the stresses of the building assignment or the use you’re putting it in for. We believe that is necessary, too, so read on to learn everything we need to learn.

Strongest Steel Tubing

Steel square tubing isn’t the most powerful type of tubing we can use. It is, however, more relevant than rounded or differently shaped tubing in specific uses.

Round steel tubing can resist far higher weight per foot than square or rectangular tubing. This advanced weight-bearing capability is because a circle is a more powerful shape than a square. Because there are no corners, there are fewer stress points to give form when extra load is involved.

Round steel tubing is also selected in multiple use cases. This is especially the case when the steel tubing is planned to move water or liquids. Round steel tubing performs better for moving liquids as there are more irregular points of resistance in its interior shape. Square steel tubing functions more suitable in terms of strength when the tube required is long. Over longer lengths of tubing, a square shape will bend less than a round one.

Square steel tubing is also selected if the tube must fit snugly into its surroundings. In such possibilities, square steel tubing can be more substantial than round because it can be connected to another tube or structure piece. For rough goals, we can reach square and round steel tubing to find out which is strongest. With an approximation in mind, round steel tubing is roughly ten moments stronger.

What Is Square Tubing?

Square steel tubing is tubing that is simulated using welding. This type of tubing is of structural quality. It comes in either kind A513 or A500 Grade B. The various kinds of steel tubes are defined by the dimensions and how dense the tube’s wall is. Still of the grade, steel tubing is utilized for a combination of objectives.

Typical benefits of square steel tubing include building and structural services. It is also utilized for a wide assortment of manufacturing and vision applications. We can find square steel tubes in vehicles, trailers, agricultural and transportation equipment, and much more. The square shape of this steel tubing is perfect for many additional reasons. It delivers power that directed or angled tubing does not. It is also better settled than directed or angled tubing.

Square steel tubing is also universal. Manufacturers like to utilize it because it is effortless to cut and weld into new applications.

How Strong Is Square Tubing?

To choose the reply to the question, of how strong is square tubing, it’s essential to evaluate how much weight it can carry. In steel tubing, the potency rating of the tube is calculated by weight per foot.

This common measurement is reasonable if we need to reach other manufacturers or outcomes. The typical measure also let us understand if the steel tubing we are thinking of will meet your structural requirements. Square steel tubing arrives in a mixture of different sizes. There are also two common thicknesses of the steel itself.

Let’s look at a pair of common sizes of square steel tubing to see how strong it is. A 2-inch x 2-inch bit of square steel tube with a wall consistency of 0.1875 inches can carry 4.32 lbs per foot of length. A 4-inch x 4-inch piece of square steel tube with a wall thickness of 0.25 inches can carry 5.41 lbs per foot of length.

As we might guess, the tubing’s larger measurements and thicker walls allow for more significant load-bearing capabilities. So, a 16-inch x 16-inch square tube with a wall of 0.5 inches can carry 103.3 lbs per foot. Square steel tubing is abundant and strong sufficiently for multiple building and manufacturing uses. It is also strong sufficiently for effective weight-bearing uses in vehicles and is greatly better.

Use Square Tubing When Needed

While square steel tubing isn’t as strong as round steel tubing, it is still solid. It also has properties, such as its shape, that make it preferable to round steel tubing in many situations.

“How strong is square tubing?” because we must understand if it will hold the weight your project needs. Work with professional architects or engineers to determine whether square steel tubing is the right material. They will also be capable of helping with operating out what size of square steel tubing we require. You’ll need to produce awareness of how much weight requires your square steel tubing to move across each foot of height. The more additional weight we must, the larger the size of the tube we will need.

Fortunately, we’re in the corporation of supplying square steel tubing, as well as lots more, and we’ve been doing it for a prolonged time. We know our tubes! We’ll work to ensure that we have the correct square steel tube where and when we must it.

Advantages of Stainless Steel Tubing

- There are several advantages to utilizing stainless steel structural tubing. The most significant is the erosion opposition effects. This is essential for many industrial applications in intolerant surroundings. Stainless steel has naturally improved heat and blaze resistance corresponding to different metals utilized in construction. It also supplies easy fraud and effortless cleaning and care. The aesthetics of stainless steel is also unpaired by various alloys or materials.

- Stainless Structurals’ tubing has distinct advantages over other tube suppliers. The foremost is the customization; in a standard welded tube, we are confined to one wall viscosity. With laser welding, we can mix and match wall thicknesses qualifying for better strength-to-weight ratios where we can decrease mass while increasing load capability. This method permits the production of non-common sizes and alloys with only a 1-length order minimum.

- The sharp corners of our tubing are also beneficial for architectural purposes, meeting or exceeding AESS guidelines. Modern architecture promotes straight edges and clean lines, which are evident in our square and rectangle tubing. Structural glass divisions also choose square hubs and straight edges for glass shows and supports.

- Body implants and most surgical and non-surgical medical equipment are made up of SS tubes. Especially, the hospital bed, which can be seen in every ward of a hospital, is one of the major uses of stainless steel in the medical sector.

- Other industries also benefit from the properties Stainless Steel Tubes have to offer, some- the manufacturing sector, aerospace, gas, defense, and nowadays also common households.

When Should We Use Square Tubing?

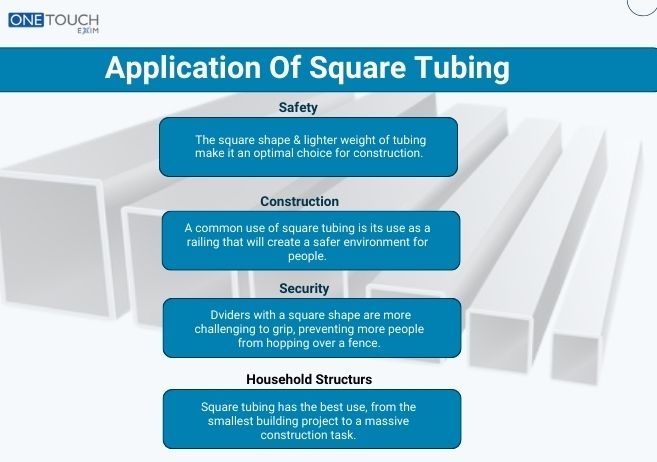

Square tubing is a versatile building material that can be used in a variety of applications. Here are some situations where square tubing is particularly advantageous:

1. Structural support

Square tubing is often used in construction and engineering projects to provide structural support, such as in buildings, bridges, and other infrastructure. Its square shape offers more stability and strength compared to round tubing.

2. Vehicle frames

It is commonly used in the construction of vehicle frames, such as in cars, trucks, and trailers. Its rigid structure can withstand the heavy loads and vibrations that vehicles experience on the road.

3. Furniture making

Square tubing is a popular choice for furniture making, especially for modern and industrial-style pieces. It can be used to create sleek and sturdy frames for tables, chairs, shelving units, and more.

4. Outdoor applications

It is highly resistant to corrosion, making it a good choice for outdoor applications such as fencing, handrails, and playground equipment. It can withstand exposure to the elements without rusting or deteriorating.

5. Agriculture and Farming

In the agricultural sector, square tubing is used for constructing livestock pens, fences, and other farm structures. Its durability and resistance to rust make it a suitable choice for outdoor applications.

6. DIY Projects and Hobbyists

Square tubing is popular among DIY enthusiasts and hobbyists for creating custom projects, such as workbenches, tool holders, and even bicycles. Its availability in various sizes and thicknesses allows for custom.

Conclusion

Square tubing has numerous advantages, making it an ideal choice for construction projects. They offer strength, durability, and stability, are lightweight, require minimal maintenance, and offer sustainability advantages. The versatility of square tubing allows people to use them across various construction projects. Based on these advantages, it’s clear that square tubing are an efficient and cost-effective solution that can enhance any construction project’s structural integrity.