Welders can perform across various industries if they have the technological and precision capabilities needed. Experienced welders can achieve certifications to boost their qualifications and specialized expertise is weld test coupons. Learning about the various welding certifications can allow a welder to select an area to expand their skills.

What are the Weld Test Coupons?

Weld test coupons that were just utilized to test a welder’s talents. These portions of metal called “coupons” have had belts carved out for dangerous testing and then reattached to the coupon behind which they were strained. For the welding process that those weld coupons were utilized for, there was a sequence of assessment measures that must be met before the welder evolves permitted on that procedure.

First, the welder satisfies the root access and it must be visually inspected (VT) and supported by the welding inspector before standing allowed to move. When the coupon is welded and released, and the final visible approval of the weld is accomplished, the weld is prepared for either non-destructive testing (NDT) or destructive testing (DT) depending on the kind of weld. In this case, the 36” butt weld coupons needed both NDT and DT. For the NDT, the whole coupon stood x-rayed (RT). After handling the RT measures, the welding coupon carried on to harmful testing. For DT on these coupons, there was a total of 12 straps cut release and prepared for testing. Eight belts were used for nick rupture tests, two straps for root angle tests, and two straps for face bend tests.

The nick tests are conducted to reveal internal defects such as slag inclusions, absence of fusion, insufficient penetration, porosity, etc. in the weld. To do this, a gap or nick is deliberately made by shortening the strap on the weld countenance to enable it to crack in the center line of the weld. The belt is then mechanically inclined to crack it and the cross-section is visually inspected for any defects.

The root and face curves are done besides but used to test the flexibility of the weld with the ground material. One set of belts is bent with the beginning of the weld to the exterior, and the other set is turned with the root of the weld to the exterior. The idea here is that the weld metal and base material should plastically twist together, and not rupture or fail. After being mechanically bent, if the belts do not fail, they are visually inspected for any defects as well.

After meeting all these conditions, the welder is determined to be prepared for the approach being tested.

The Importance Of Weld Test Coupons

There is an often-used expression in our industry: “Evolution.” I utilize it a bunch, too, but what if we strolled out from something unique for a point and concentrated on something that is not unique? I wish I had your interest if it’s not useful news. There are times when we can and must pause from all of the new things being thrown at us and revisit a not-so-new process that far too many shops are not performing. As I’ve traveled around the country over the past few years, the subject of performing test welds has come up too often in the wrong context. I’ve been a bit surprised at the lack of understanding on the subject. We’ll protect those misconceptions and additionally importantly the reasoning behind why it ought to be done.

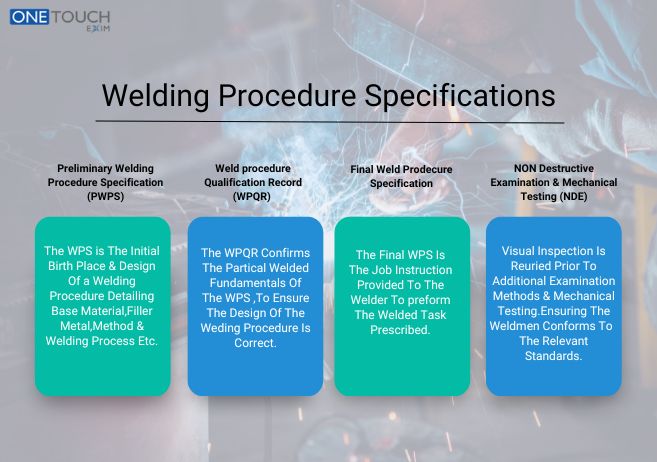

A Welding Procedure Specification, or WPS, is critical to creating uniform, high-quality outcomes with the belief that they will resist the anticipated usefulness conditions. A WPS goal is to describe proven welding parameters procedures to coach welders as they weld elements. It can be considered similar to a formula and contains any crucial data and details needed to provide a weld is the most useful it can be.

What Is In A Welding Procedure Specification?

Welding Procedure Specifications are necessary no matter how participated your welders are. They act as a protection to prevent welding faults, limit corporation penalties, and keep the highest possible criteria. Your WPS will include proven and tested methods that cover details such as:

- Proven way of welding a given material

- What common setup works

- Strategies to utilize

- Proven welding device surroundings like amps, volts, and travel speed

- Step-by-step processes to track, including preheating conditions, which fill metals to utilize, and proven welding machine settings like amps, volts, and travel speed.

Welding Certification

A welding certification is a hands-on capability test performed by experienced welding teaching associations or qualified welding inspectors to define and confirm a welder’s techniques and skills. Welders can achieve these certifications when they give reviews and earn certificates. Some certification exams test a welder’s ability, while others test the functional application of typical welding processes. Here are common welding skills generally tested to obtain these certifications overhead, flat, vertical, and flat welding classes, 6G pipe welding, gas tungsten arc welding, gas metal arc welding, flux center arc welding, and covered metal arch welding.

Various certifications are unrestricted for welders, normally testing skills such as welding works, welding methods, metal viscosity, and metal types. Testing is usually clear to a welding talent set, and the finished certification is used only for that detailed skill. If welders like to grow their talents in better than one place, they may need multiple certifications.

Why complete a certification in welding?

Achieving certifications offers future employers that you maintain expertise in your desired occupation. Technological certificates add importance to other experienced qualifications you may control and can enhance your probability of victory when used for welding jobs. These are the advantages you may visit from completing these specialized certifications:

- Delivers access to more job possibilities

Certifications may assist you qualify for appointments across different industries, as each industry may need various skills.

- Requires minimal regeneration expenses

Once you’ve achieved a certification, it’s often required to recertify at typical breaks. The cost for regeneration is usually low and generally affordable to keep.

- Demonstrates your skills

Certifications can spotlight heads in the welding enterprise who have proficiency in a specialized area.

- Demonstrates your versatility

If you complete a few certifications, it emphasizes that you have considerable skill sets and can show your versatility to a leader.

- Provides improved job stability

The expertise and knowledge you boost from certification may assist you prepare for a more reasonable range of endless positions.

- Validates competency

Certification tests yield stringent measures. Certification can confirm your capacity to deliver grade welding work.

Conclusion

Professionals in welding operate in a variety of weather conditions, indoor and outdoor environments, and small areas. Their work demands physical stamina, spatial orientation, and attention to detail. Workplaces range from shipbuilding to welder shops.

Tests for certification and qualification guarantee that the welder is capable of producing high-quality work with few defects.