Metal forming operation is converting the shape of a metal work piece by compressive forces without increasing or decreasing material volume. Some key types are rolling (to make sheet, bar, etc forging (to make crankshafts, etc), Extrusion (to make pipe, etc), drawing (to make wire etc), and sheet forming (eg deep drawing for cups) and stamping (automotive body panels). These mechanisms improve mechanical properties through finer grains. Applications range from automotive (body panels, engine parts), aerospace (structural parts), construction (beams, frames), and consumer goods (cans, utensils). Their productivity, material savings and capability to produce the high-strength parts is indispensable for the manufacturing.

What is Metal Forming Used For?

Metal Forming is a process used to produce a wide variety of components possessing phenomenal strength and integrity. This method of manufacturing is important for the manufacture of high strength, complex shaped parts used in automotive (e.g. car body panels, engine crankshafts), aerospace (structural airframe components) and construction (beams, frames). It is also essential for making common household items such as beverages, utensils and hardware. Since they plastically form the metal into its own design form without wasting, they allow to attain both the good mechanical properties and the material efficiency, as well as the mass-production ability for a final durable and reliable product.

Common Types of Metal Forming Processes

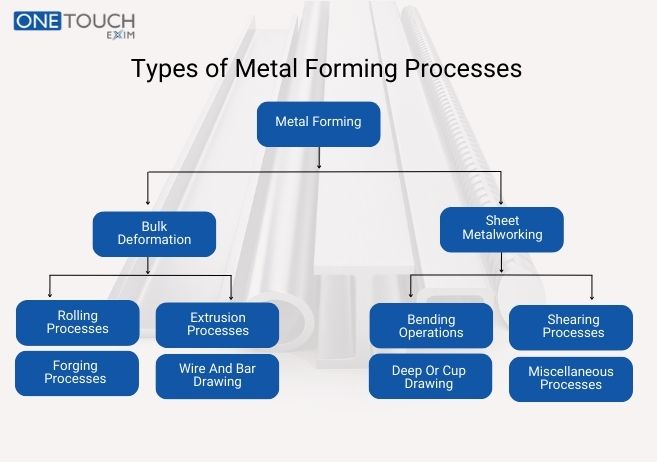

Metal forming is a broad term for a group of manufacturing processes in which plastic deformation of the work piece occurs to achieve the components desired shape. They can be split into two groups according to the following method; bulk and sheet forming. Bulk forming processes refer to severe shaping with large change of initial mass workpiece. Key types are:

Rolling :

Metal forming process in which metal is passed through rotating rolls to reduce thickness and produce uniform cross section such as sheets, plates and structural beams.

Forging :

Process of forming metal by the localized application of compressive forces, usually with a hammer or die. It makes durable parts, including crankshafts and wrenches.

Extrusion :

The process of forcing a metal billet to flow through an opening in a die, forming a long, continuous product with a specific cross section, such as rods, tubes and aluminium window frames.

Wire Drawing :

The pulling of metal through a die to reduce its dimensions, which is the process for making wire, rods and tubes.

Sheet forming operations are carried out on a very thin and flat surface of metal. Prominent types are:

Bending :

Applying force on sheet metal to bend it around a straight axis.

Deep Drawing :

Creating a hollow cup like form such as automotive body panels or kitchen sinks out of a flat sheet.

Shearing :

Physically punching, forming or blanking sheet metal into parts through presses and dies, it is a necessary process for volume production of components such as brackets and connectors.

Common Metal Forming Materials

Common metal forming operations are conducted on ductile and malleable materials. The low carbon steels are the most used of the steels, but have a relatively wide distribution of strength, forming properties and cost making them ideal for auto body panels and structural members. Aluminium alloys are preferred because of their light weight and corrosion resistance and are found in aerospace components as well as beverage cans. Stainless steels with resistance to corrosion and heat could be used in kitchenware, chemical reactors. Copper and its alloys such as brass and bronze are used in electrical conductors and in parts for plumbing for the same reasons their use is specified by many other industries : conductivity, resistance to corrosion and attractive appearance. They are satisfied when it is possible to combine workability with the ultimate performance requirement of the end use.

Advantages of the Metal Forming Process

Metal Forming has many advantages over other methods of manufacture. Work hardening and grain size refinement drastically increase mechanical properties like strength and toughness. Such processes are very cost effective for high volume production due to the fact that in transforming metal materials shape there is very little waste material generated as compared to a removal process. They make it possible to manufacture intricate, high strength parts with fine detail and good surface finish. In addition, the potential to produce parts of uniform quality with high structural integrity makes the material essential for vital industrial sectors such as automotive and aerospace.

Disadvantages of the Metal Forming Process

Key disadvantages in metal forming processes are expensive initial investment in powerful machinery, complex tooling and dies, hence less cost effective for low production volume. The procedures also need a high energy input with which to distort – frequently high strength – either such materials. There are material constraints, since not all metals are as ductile to be molded without cracking. In addition, part design is limited by the requirement for draft angles and consistent wall thickness to facilitate forming. Secondary finishing processes are also often necessary in order to reach the final tolerances and remove surface defects that are caused by the deformation at the high stresses.

Conclusion

Metal forming is a cornerstone of the manufacturing sector and a process type that is required for producing high strength and high-complexity components in the automotive, aerospace and consumer products industries. Certainly, the high initial cost and the material restrictions are limitations ; however, the advantages of high mechanical properties, material efficiency and high volume production cannot be ignored. At the end of the day, its ability to craft dependable, long lasting components with little wastage earns it the crucial position in today’s industrial production.