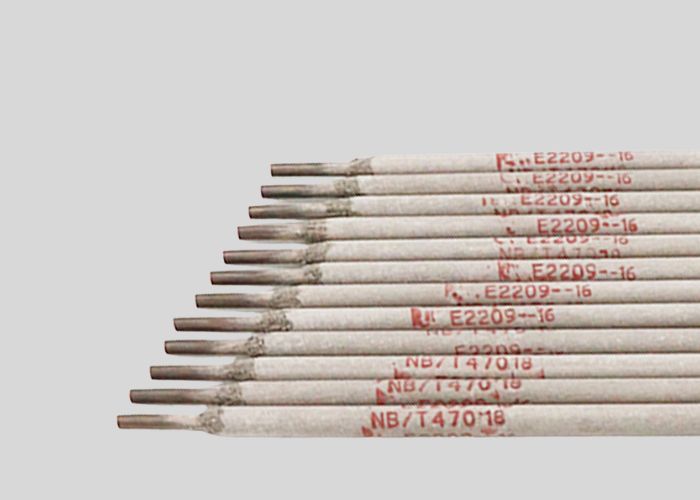

Welding Electrode/Rod

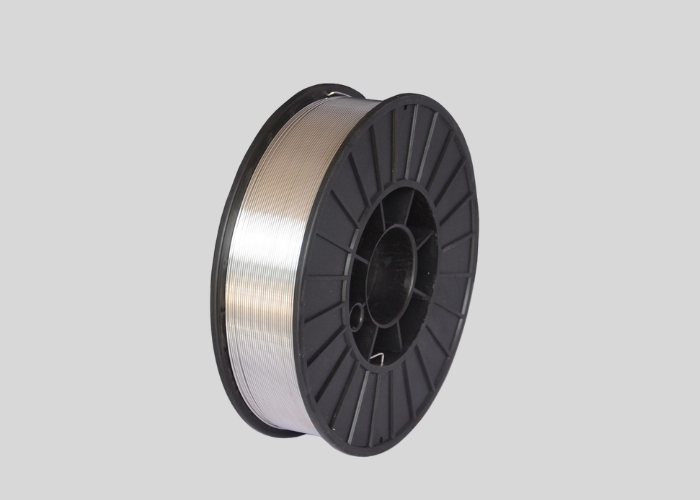

At OneTouch Exim, we offer a diverse range of the best-quality welding electrodes and rods designed specifically for the Indian market. Our premium-quality welding rods ensure superior performance and durability for various applications. Whether you're involved in MMA (Manual Metal Arc) welding, TIG (Tungsten Inert Gas) welding, or MIG (Metal Inert Gas) welding, our electrodes deliver excellent arc stability and minimal spatter, resulting in clean and strong welds.

Our selection includes mild steel, stainless steel, and specialty alloy electrodes, providing the versatility needed for different welding processes. We understand the unique requirements of the Indian welding market, which is why our products meet local standards while remaining affordable. With a commitment to quality and customer support, our team is here to assist you in selecting the right welding solution for your projects. Experience the difference that our high-quality welding products can make in your work. Choose OneTouch Exim for all your welding needs and elevate your projects with reliable solutions that stand the test of time.