| TYPE | DESCRIPTION |

|---|---|

| SHAPE | Stick (Rod) |

| HARDNESS | Approximately 180–200 HB |

| CERTIFICATION | AWS A5.4 / ASME SFA 5.4, ISO 3580-A: E 23 12 L R 16 |

| TENSILE STRENGTH | Minimum 550 MPa |

| YIELD STRENGTH | Minimum 350 MPa |

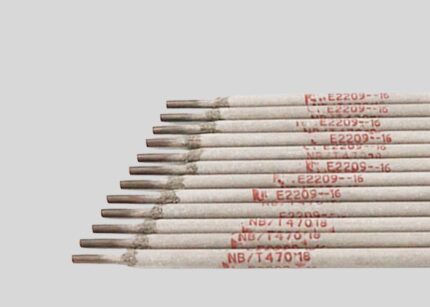

E309L-16 stainless steel electrodes

The Stainless Steel electrode is used in specific stainless steel applications and overlaying carbon steels. The AWS classification information is that using E-309L contains : – “E” designates an electrode – “309” the chromium-nickel composition of the weld metal itself, – “L” means a level low carbon content (often less than 0.04%) and finally “16” tells us about a lime-ferritic coating suitable for both ac and dc reverse polarity.

E309L-16’s primary purpose is for joining low carbon 22% Cr-12% Ni Steel to Stainless Steel & some dissimilar steel welding stainless. The 309 chemistry has a nominal 23% chromium/13% nickel that produces an austenitic weld deposit that will not harden from machining and remains ductile. This negates the formation of hard crack-prone martensitic areas and is suitable for cladding or transition joints.

The low carbon “L” form of 304 is required when the material must have corrosion resistance in welding applications; this lower carbon composition is used for such applications. The all positions welding, low hydrogen “16” electrode produces X-ray quality deposits on medium carbon and low alloy steel having tensile strength up to 70,000 psi.

Typical applications would include the joining of 304 type stainless steel to carbon steel as well as dissimilar welding; it is used for high tensile strength materials at elevated temperatures. Function: It is used in maintenance and general fabrication.

Description