| TYPE | DESCRIPTION |

|---|---|

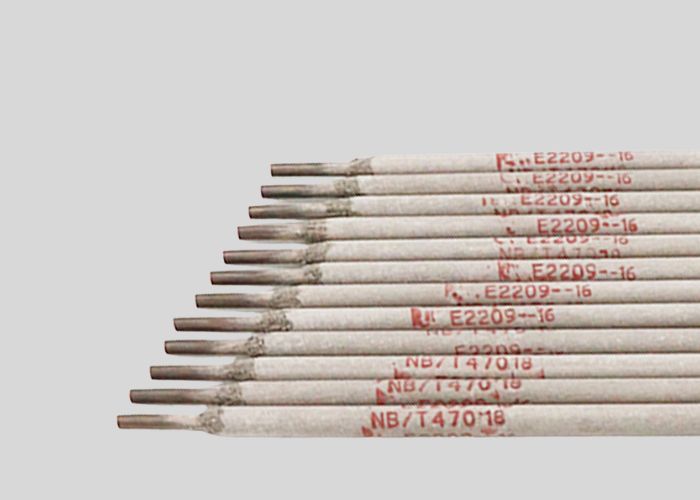

| SHAPE | Stick (Rod) |

| HARDNESS | Approximately 250 HB |

| CERTIFICATION | AWS A5.4 / ASME SFA 5.4: E2209-16, ISO 3580-A: E 22 9 3 N L R 16 |

| TENSILE STRENGTH | Minimum 620 MPa |

| YIELD STRENGTH | Minimum 450 MPa |

E2209-16 duplex stainless steel electrodes

General description and application E2209-16 is a flux cored arc welding electrode material for welding 22Cr duplex stainless steels. The “E2209” means weld metal that has a composition of 22% Cr and 9% Ni and the “-16” suffix letter indicates a lime ferritic coating that is used with the DCEP (Direct Electrode Positive) polarity and all positional welding.

Key Features and Benefits :

E2209 has an all position balanced austenite-ferrite microstructure similar to that of the base metal. This balance is important because it gives an excellent combination of strength (about twice that of standard 309 electrode) and tenacious resistance to stress corrosion cracking, pitting and crevice corrosion. It is typically strong enough to reduce the thickness of the cross section, saving weight and expense.

Common Applications :

Industry standard products for the joining of duplex and super-duplex stainless steels, including those used in a range of demanding sectors. Common applications include :

- Marine and Offshore : Submarine and riser and topside process equipment.

- Oil and Gas : Pressure vessels, heat exchangers, and pipe distribution system conveying acidic process liquids.

- Chemical processing : Tanks, reactors and piping that are exposed to chlorides.

- Pollution Control and Pulp & Paper Industry machinery.

Welding applications :

This type of welding makes E2209-16 have the ability to produce high quality and metallic alloy weld deposits. The crucial issues are to control the heat input in the range of 0.5 to 2.5 kj/mm and to keep the interpass temperature relatively high. This control is necessary in order to maintain the desired ferrite-austenite ratio (target is around 40-60% ferrite) in the weld metal (WM) and also in the Heat-Affected Zone (HAZ) in order to achieve the best corrosion resistance and mechanical properties. Preheating is generally not required.

Description