| TYPE | DESCRIPTION |

|---|---|

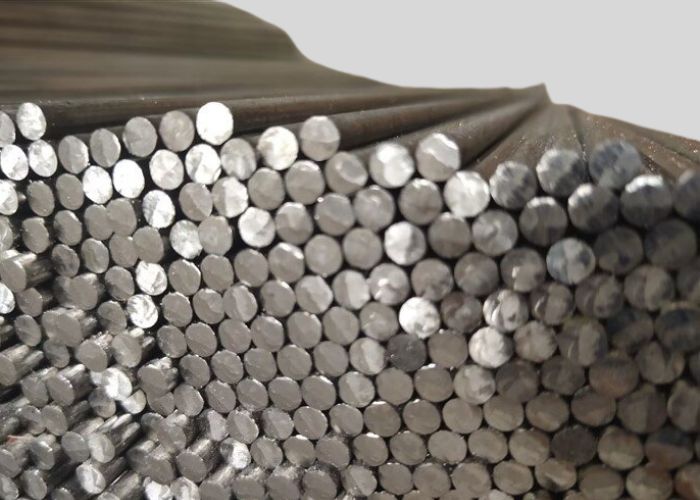

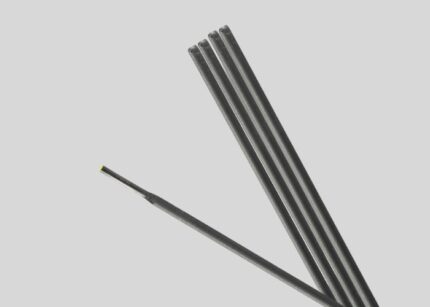

| SHAPE | Cylinder |

| HARDNESS | Brinell 180 |

| CERTIFICATION | AWS A5.15/A5.15-90 (R2006) |

| TENSILE STRENGTH, kpsi | 40-65 |

| YIELD STRENGTH, kpsi | 38-60 |

Nickel 55 Welding Rod

The Nickel 55 Welding Rod is a high-performance nickel alloy electrode specifically designed for welding applications requiring excellent corrosion resistance and high strength. Composed primarily of nickel, this welding rod is ideal for joining dissimilar metals and is particularly effective for welding nickel to stainless steel and other alloys in industries such as petrochemical, aerospace, and marine engineering. The Nickel 55 rod offers exceptional ductility and impact resistance, ensuring strong, reliable welds in challenging environments. Its low thermal expansion and superior resistance to oxidation and carburization make it suitable for high-temperature applications, providing long-lasting performance and integrity in welds exposed to extreme conditions. Meeting stringent industry standards, the Nickel 55 Welding Rod is the preferred choice for professionals seeking a dependable solution for high-quality welding that delivers optimal results in demanding applications.

Category: Nickel Electrode/Rod

Description