| TYPE | DESCRIPTION |

|---|---|

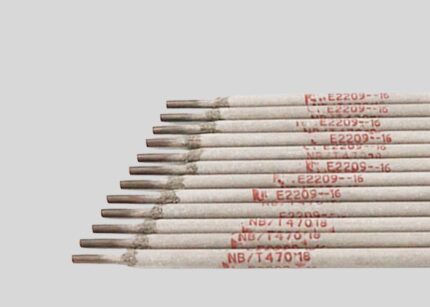

| SHAPE | Stick (Rod) |

| HARDNESS | Approximately 200–220 HB |

| CERTIFICATION | AWS A5.4 / ASME SFA 5.4, ISO 3580-A6 |

| TENSILE STRENGTH | Minimum 520 MPa |

| YIELD STRENGTH | Minimum 310 MPa |

E502-16 welding electrodes

The E502-16 is a low hydrogen type carbon steel electrode under the AWS A5.1 standard. It is intended for applications where high tensile strength, joint flexibility and all positions welding is required. Its classifications provide key information :

- E : Electrode

- 50 : As welded tensile strength, minimum of 50,000 psi.

- 2 : The third character indicates that it is commonly used for flat and horizontal positions.

- -16 : Low-hydrogen potassium, great for use with Alternating Current (AC) and direct current electrode positive (DCEP).

Key Characteristics and Advantages :

- Low-Hydrogen Coating The “-16” is essential. It stands for a moisture resistant coating which will significantly lower the chance of hydrogen-induced cracking (HIC). It is recommended for welding high strength carbon and low alloy steels, high carbon steels, high sulfur steels, steel castings and forgings.

- AC TIG (GTAW) : Weld on aluminium and other materials that are AC compatible. Formerly used only on transformer style machines and now available on all inverter products.

- Good Mechanical Properties : It develops welds with good strength and moderate impact properties and it’s acceptable on a variety of applications with good sound weld metal.

Applications and Uses :

E502-16 is a heavy coated, low hydrogen electrode for welding carbon and most carbon molybdenum weld steels. Its primary applications include :

- General : Structural fabrication in building and bridge construction.

- Shipbuilding and pipe welding.

- Repair welding on machines and steel equipment.

- Welding of boiler plate or pressure vessel and similar high strength construction.

Critical Applications :

In order to preserve the low hydrogen characteristics of E502-16 electrodes, they must be stored in a hermetically sealed container or a heated holding oven. If exposed to air at room temperature, they must be baked out of absorbed moisture as per the manufacturer’s recommendation before application.

Category: Plain Chrome Stainless Steel Electrodes

Description