| TYPE | DESCRIPTION |

|---|---|

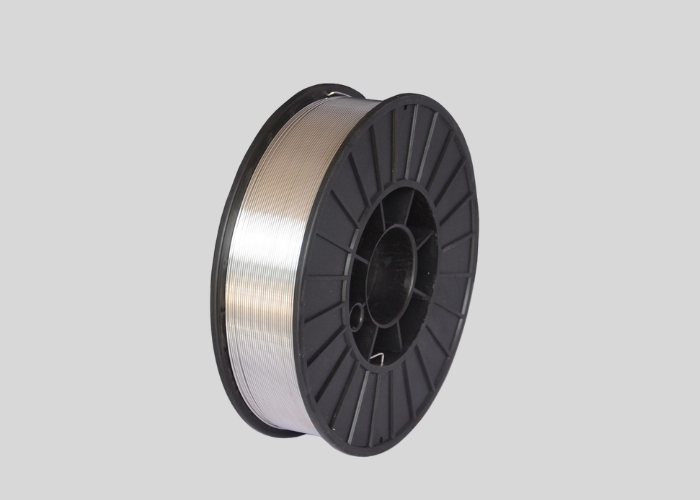

| SHAPE | Wire (Spool) |

| HARDNESS | Approximately 170–210 HB |

| CERTIFICATION | AWS A5.20 / ASME SFA 5.20, ISO 17632 |

| TENSILE STRENGTH | Minimum 480 MPa |

| YIELD STRENGTH | Minimum 370 MPa |

E71T-1 tubular electrodes

E71T-1 is a designation from the American Welding Society (AWS) for a particular type of gas-shielded, flux-cored arc welding (FCAW-G) electrode. It is an all-positioned wire that can be used for anything from general fabrication to light industrial work.

The “E” indicates an electrode. “71” that’s the minimum tensile strength (70,000 psi). “T” is for tubular, meaning flux-cored. The “-1” indicates the torch is intended for CO2 shielding, a cost saving option.

The high deposition rate of E71T-1 electrodes is one important feature that sets them apart from both stick (SMAW) and solid wire (GMAW). This results in very efficient welding for manufacturing and construction applications. The flux core gives a deep, penetrating arc and leaves behind a heavy slag that covers the weld. This slag system makes possible the all position welding (flat, horizontal, vertical and overhead) by deposition of the weld pool in such a way shaped that it is held up by the flux. It is also what makes the electrodes a top performer on mill scale and light contaminants in steel.

The welds produced have a smooth spray-like transfer with low spatter and aesthetically pleasing bead shape. E71T-1 electrodes are capable of producing welds with 100% CO2 shielding gas and can be used in structural applications.

The E71T-1 offers the best values in quality and cost when it comes to open arc welding of thin gauge, high carbon, all type steels and several other construction materials.

Category: Tubular Electrodes

Description