A well-known & highly usable metal, stainless steel is a major part of our daily life. But do you know what stainless steel is, its composition, types & facts? Here in this blog, we cover all the information regarding stainless steel, how it’s made & what quality of stainless steel makes them a highly demanding metal.

Stainless steel is made from a two-step process of the major compounds carbon and iron. Its origin is formed by mixing many metals from the earth, which are such as nickel, copper, silicon, nitrogen, and manganese. Steel consists of chromium and carbon and alloyed, metallic, or nonmetallic chemical elements. Stainless steel is made of iron alloys that do not rust and are known to be heat resistant. This steel provides more corrosion resistance than other steel. It is made of a mixture of iron and iron. Chromium plays a major role in this.

The best composition of the stainless steel depends on the quality, application, and desired properties. Many types of steel are used in a wide range of applications such as household appliances, automobiles, building contractions, medical equipment transporters, and pollution. Steel with a high level of chromium in the alloy forms a protective layer on the metal surface that prevents tarnish and rust from forming. It exposes the environment to water, air, and other corrosive substances.

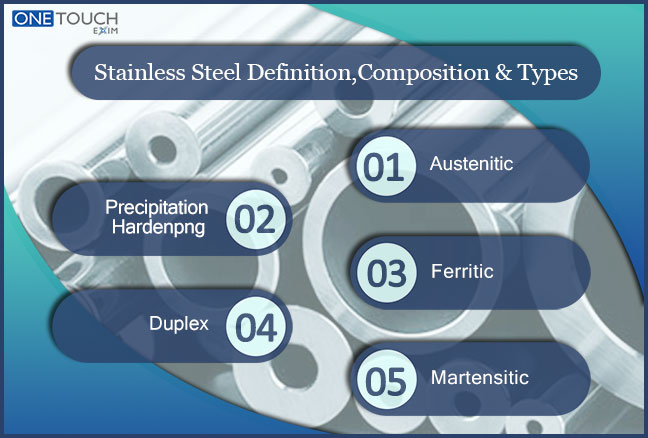

What are the types of stainless steel (SS)?

Stainless Steel is used in different types of Iron-based alloys, the most common type of Stainless Steel such as Austenitic, Ferritic, Martensitic, and Duplex. Below, get more inquiries about the most trending types of stainless steel,

- Austenitic- Austenitic is the most common type of Stainless Steel and it is used in a wide range of applications like medical equipment, Cultery, and kitchen appliance. It is known as ductility, strength, and resistance to corrosion.

- Precipitation Hardening- The category of this metal stainless steel contains Nickel, Chromium, aluminum, niobium, and copper. It gives resistance and higher strength than other types of stainless steel.

- Ferritic- The Ferritic metal is made with chromium & less carbon which gives them high strength. This metal is widely used in building construction, automotive parts & industrial sector. It gives low ability anti-corrosion than other steel.

- Duplex– This stainless steel metal is a mixture of ferritic & austenitic. The combination of these two metals with the composition of Nickel, Chromium, Molybdenum & copper provides them more strength. This metal is often used in making tanks, chemical processes & more.

- Martensitic- This steel is made of a high mixture of carbon and chromium. It uses a moderate level of resistance and high strength where needs these types of stainless steel.

What are the uses of stainless steel?

Stainless steel is a versatile material that resists corrosion and rust in a variety of applications. It is made from a combination of several alloys. Here are several applications for stainless steel. For sinks, cooking utensils, and refrigerators, this steel has shown to be quite handy.

Stainless steel is widely employed in modern society. Due to its strength and resistance to corrosion, it is frequently used in buildings, lift doors, vehicle grills, and many other applications. It can tolerate environmental conditions better than other steels. Because of its sanitary qualities and great wear resistance, this steel is utilized in the medical and healthcare industries. It is used in surgical equipment, medical devices, and implants.

Composition property of stainless steel

Stainless steel is a widely versatile used material. It is unique composition and properties. It is alloys types of steel that apply contains a small amount of 10.5% chromium by mass. This chromium contains is what gives stainless steel it prevents exceptional corrosion resistance.

One of the basic properties of stainless steel is its good ability to resist rust and corrosion. It makes, suitable for a wide range of applications, from industrial machinery to kitchen utensils. Which can easily corrode when exposed to certain chemicals or moisture, with an invisible layer of chromium oxide on its makes on the surface. This layer works as a protective barrier, preventing the underlying steel from coming into contact with corrosive elements.

Important facts about stainless steel

Stainless steel is a remarkable material that has several properties that make it highly valuable and used in various industries.

Corrosion Resistance- stainless has known for its quality which makes it excellent and resistant to rust and corrosion. This property is due to the presence of chromium in the alloy, which forms a thin protective layer that prevents the steel from reacting with the environment.

Easy maintenance and hygiene- This steel is smooth and non-porous, making it easy to clean and resistant to bacterial growth. It is mostly used in health care, pharmaceutical industries, and food processing, where cleaning and hygiene play the most important role. This steel has a sleek and modern look attractive, reflective surface, it is often used in interior designs, decorative elements, and more.

Conclusion

Stainless steel is a model structure of metal that offer anti-corrosion & high strength. This recyclable metal retains its same property after recycling in its own natural form. Stainless steel is one of the highly demanding metal products which comes in various grades & finishes that allow it to be tailored to specific applications. It has a high resistance to fire and heat, which it makes suitable for applications in high-temperature environments, making it ideal for applications such as exhaust systems, furnaces, and industrial ovens.