Stainless Steel is the popular name for a variety of factory-made corrosion-resistant alloys that were developed decades ago due to the sturdiness and its resistance to corrosion. This material is incredibly durable, hygienic and keeps its appearance for longer than any other commercially available surface – which makes it perfect for use in tough commercial environments, food processing, medical appliances as well as architectural and design installations! But it’s more costly and more difficult to machine than carbon steel.

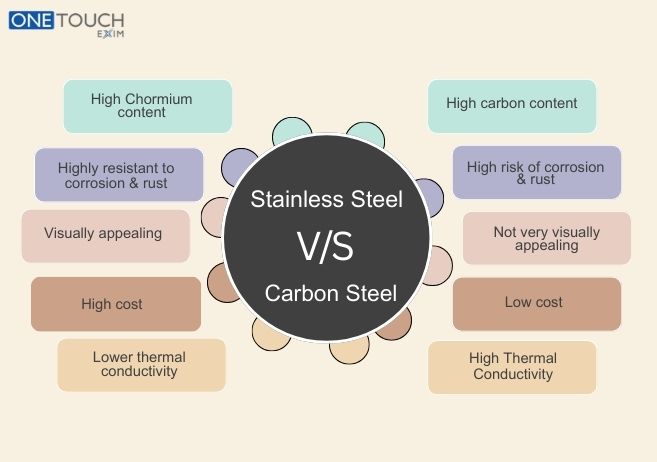

Comparing Stainless Steel with Carbon Steel

Stainless Steel is an iron alloy with resistance to staining and rusting in many typically degrades. It’s more costly and difficult to machine, but you get strength and a polished look.

Carbon steel, however, with up to 2.0% carbon content in the case of high carbon steel, gives priority to strength and hardness while being economical. It is readily welded and is used in construction, machinery and automotive frames. But it has no corrosion resistance at all and needs sleeves to protect it.

Pick stainless for corrosion-sensitive or decorative applications; pick carbon steel for high-strength, cost-sensitivity ventures where rust can be maintained.

Benefits of Stainless Steel

Stainless steel provides an excellent area of corrosion resistance as well and is able to withstand moderate-moist environments, chemicals and extreme temperatures without losing quality. It is durable and strong, long-lasting and structurally stable; it allows for food safe rigid packaging or other medical or hygiene products. The material is also extremely sustainable at 100% recyclable. Stainless steel offers an excellent combination of high strength, cleanliness and good looks with low maintenance (architectural, industrial and consumer products).

Benefits of Carbon Steel

Plain carbon steel has the highest strength among all types of metal materials, but it is also the brittlest. It’s inexpensive compared to the stainless steel alloys and so is cost friendly for large projects. It is machinable and weldable, so it is easily fabricated or repaired, while unprotected surfaces are susceptible to rust, processability is more important for exposure durability (e.g. painting). The predictability of carbon steel displays no sign of brittleness, enabling it to insulate dampness for long periods without cracking or flaking invention.

Stainless Steel Applications

Its outstanding properties have made it the material of choice across industries. Its corrosion resistance makes it otherwise suitable for use in marine environments, chemical plants or anywhere with exposure to corrosive cleaning agents. Food processing equipment, medical instruments and kitchen appliances benefit from a surface that is easily cleaned, quick to rinse and stain resistant. In building and development, it adds longevity and a contemporary look to cladding, handrails and structural objects. The automotive and aerospace industries have turned to exhaust systems and turbines because of its resistance to heat. In addition to strong recyclability, the material promotes sustainable design in consumer goods – including cutlery and watches for their long service life and safe use across applications.

Carbon Steel Applications

High strength and cost-effective, it is used in heavy industry and infrastructure. It is widely used for structural beams, columns and reinforcements, like rebar before it sets. In the auto industry it is used to produce chassis components, brackets and gears. Machinability of it all contributes to the processing machine, tool and pipeline. Carbon steel also plays a crucial role in railways, shipbuilding, and storage tanks. Although susceptible to rust, GTS coatings greatly extend its use in outdoor and corrosive environments where the expense of stainless steel is not justified.

Choosing the Right Type of Steel

Picking the perfect steel needs to be based on your project’s fundamental necessities. Choose from one of the many steel pipe options that find their applications in a variety of industries, such as gas and fluid or line pipes. In Structural applications, steel tube is the most widely used product with strongest and biggest demand with precise size, high strength and tight supply that connect almost all industries such as metal products as machine or building. For demanding environments or when hygiene is a concern, it defines the standard for corrosion resistance as well. Needless to say, give first 2nd priority from a key compete condition; inward pressure resistance and external structure fit, windproof.

Final Verdict on Stainless Steel and Carbon Steel

There are no good vs bad in the contest between stainless steel and carbon steel, It’s all about matching the product with the applications ultimately. The Stainless 304 finish is on and tear when you have it installed with a professional. High Strength application in construction and machinery would be good examples of where carbon steel tubing would be preferred. Although it does require additional protection from corrosion. Stainless is long lasting and low maintenance; carbon on the other hand, offers brute strength for less cash. The verdict: Use stainless for corrosion-challanged or public-facing projects; use carbon when building a structure, one appealing to eyes unseen or counting pennies after buying your tools.

Conclusion

There are applications-based reasons for choosing Carbon VS Stainless Steel. Chromium content and resistance to oxidation make stainless steel ideal for harsh environments, hygiene sensitive surfaces, or as a decorative material. Carbon Steel is the most commonly used material if high strength is required and at least moderate impact resilience. It is also considered to be the cheapest metal for use when needing this type of strength. Opt for stainless and enjoy longevity in punishing or visible location; go with carbon if you are aiming solely for cost effective strength where corrosion isn’t an issue. They have their unique applications depending on the surroundings, coast…… performance needed.