There are two types of Welding electrode rods, consumable and non consumable. Filler and consumable electrodes, such as those used in shielded metal arc welding and gas metal arc welding, add materials to the joint that form part of the completed weld. These range from coated rods like E6010 for deep penetration or E7018 for strong, clean welds to bare wire for MIG. Non consumed electrodes, such as tungsten are used when carrying out a TIG process and remain intact and only create an arc which melts another filler rod. It is dependent on the base metal, the strength of the weld that is desired and the welding process that is being used.

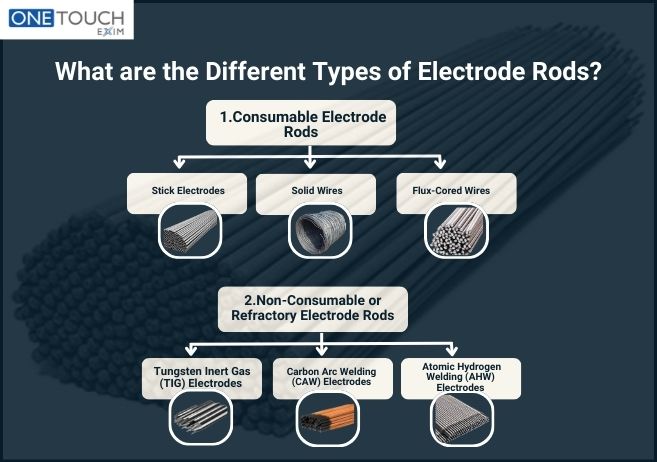

Types of Electrode Rods

Welding electrodes, also known as welding rods or simply “sticks” or “electrodes”, play an essential role in a number of welding procedures. They are further classified as two basic types i.e. Consumable type and Non-Consumable electrodes. The selection of one or the other is determined by the welding process, base metal, and the quality requirements of the weld.

1- Consumable Electrodes :

These electrodes will consume as they melt into the weld, providing material for the weld bead. They are the most commonly utilized and are great for short circuiting transfer such as SMAW, MIG and FCAW.

- Shielded Metal Arc Welding (SMAW) “Stick” electrodes – These are metal rods (core wire) covered with a material to supply a given quality of flux. The flux covering plays two important roles, as it generates a vapour to shield the weld pool from the atmosphere during welding and provides a layer of slag over the weld which protects the hot weld, as it cools down. They are identified by an organized numbering system (such as E6010, E7018)

- E6010 and E6011 : Deep – penetrating electrodes that can penetrate rust, paint and dirt. Great for use on dirty or rusty metals and in welding applications on pipes.

- E7018 : Low-hydrogen, all positioned electrode that produces strong, ductile welds with smooth ripples. It is very popular in structural steel work.

- E6013 : A general purpose electrode, these sticks are light and easy to control, with a smooth and stable arc, ideal for beginner welders, for thin and clean sheet metal welding and many other small jobs.

- Uncoated Electrode – These are just wires with no cover or coating and are mainly utilised in Gas metal Arc Welding. The inert gas for shielding comes from an external bottle. They come with high speed, efficiency and tig welding.

- Flux-Cored Electrodes – The flux is filled in tubular wires. They have the same efficiency as continuous wire feed, but you can use it on the go and with a flux that protects the weld. They can be used with or without external shielding gas, so they are extremely convenient whether you are out on the job or doing heavy fabrication.

2- Non-Consumable Electrodes :

As the word suggests, these electrodes do not melt in the weld process. They are only designed to create the welding arc and keep it live. If necessary, a secondary filler rod is commonly added by hand. They are used almost exclusively for Gas Tungsten Arc Welding.

These electrodes are constructed from tungsten, in large part because of its very high melting temperature. Tungsten is alloyed with various other metals to provide a range of different performance.

- Pure Tungsten – For use with AC welding of aluminium and magnesium. It forms a clean balled end.

- Thoriated – Red Superior arc starting and stability, used primarily for DC welding of carbon steel, stainless steel, nickel or titanium.

- Lanthanated – Gold/Cobalt Blue : These non-radioactive electrodes are primarily used for DC welding with all materials and AC welding with aluminium and magnesium. Superb for both AC and DC welding output.

- 2% ceriated – Gray : Another non radioactive option, incompatible with AC or DCRP, best for low-current DC welding, it is good for smaller parts.

There are Some Commonly Used Electrodes:

The most common types are consumable Stick Welding Electrode, identified by a number in the E60xx and E70xx numbering system. The E6013 is an all purpose electrode, which can be used with DC+, DC-, or AC. It is compatible with light gauge steel, clean sheet metal and light impurities. If you are welding for strength and structural integrity, including the E7018 is a good idea; it’s an all-position, low hydrogen rod that is noted for making strong, ductile welds on steel. E6010/E6011 rods are unbeatable to achieve deep penetration on dirty or rusted metal. In TIG torches the standard Tungsten Electrodes of choice for DC welding Steel are 2% Thoriated or Lanthanated non consumable. These types of Tungsten allow the TIG arc to start and keep a quality arc very well.

Materials That Are Used in Electrode Rods:

The electrode shaft is made up of a core wire and usually a specific covering. The core wire will normally be of the same composition as the base material i.e. mild steel, stainless steel, nickel alloy or aluminium. This wire melts to create the weld puddle.

The flux covering is a compound of mineral, metal and chemical. Important ingredients include cellulose to shield the gas, rutile for arc stabilization, iron powder to maximize metal buildup and limestone or fluorite to produce a basic slag. Non-Consumable TIG electrodes are typically composed of pure tungsten or a tungsten ally such as thorium or lanthanum.

Specifications and Applications of Electrode:

Standards for the specifications of welding electrodes are described by AWS A5 codes. 1, which indicates key properties. For instance, an E7018 electrode breaks down as follows:

- E : Electrode

- 70 : The minimum tensile strength is 70,000 psi

- 1 : Welding position (all positions)

- 8 : The flux coating type and current type (low-hydrogen potassium, AC/DC+)

Specs are picked from these :

- E6010/E6011 : Enables a deeper penetration when welding dirty, rusty steel work in construction, ship building and pipe welding.

- E6013 : Provides a soft arc with ease of application and good penetration on a wide range of applications such as general fabrication, maintenance repair and clean sheet metal.

- E7018 : A low-hydrogen rod, E7018 is used for common, high-tensile welds on mild and low-alloy steel when good impact toughness is required such as structures (girders, plates, piling).

- Stainless Steel (e.g. E308L-16) : Used to weld type 304 and similar or dissimilar types such as E308L-16 applied to food processing equipment, automotive parts and concrete stone work.

- Tungsten Electrodes : Ideal for use in torches used in TIG welding of raw aluminium and thin-gauge stainless steel.

Functioning and Advantages of Electrode Rods:

Functioning :

The function of an electrode rod is to conduct electric current from the welding machine to the base metal that would produce an arc which then causes enough heat to melt the metals. This arc liquefies the base metal as well as the end of the consumable electrode wire. The flux coating of Stick (SMAW) electrodes also vaporizes at the same time, producing a shielding gas to protect the molten weld pool from contamination by oxygen and nitrogen in the atmosphere. It also creates a slag cover which shields the cooling weld.

Advantages :

The number one advantage is simply portability and simplicity; Stick Welding requires very little equipment that is easily moved, so it is great for farming, construction and home repairs. They are also compatible with a wide range of materials; from steel, rusty or painted to the most exotic alloys. It is cheap and a large labor force has the process down to a science. That in addition to the unique advantages certain rods have to offer; E6010 penetrates deep and works great in dirty metal and metal types, whereas low-hydrogen rods (E7018) makes stronger and crack-resistant welds, both with their own strengths and weaknesses.

Conclusion

Electrode-rods are essential in welding, and they are classified as a kind of consumable and non-consumable type. Their choice is important, based on the characteristics of the base metal, the required strength of the weld and the application-whether it’s the brutish stick rods for construction projects, or the precision of TIG tungsten rods for aerospace-grade aluminium. Knowing how to select an electrode with the right kind of strength, composition, and flux is a very important skill for anyone wanting to make strong and high quality welds, since the proper electrode selection is the root for suitable fabrication and repair work.