6010 : Fast Penetration cellulose for dirty/rusty steel pipe. Requires DC power and skill. Produces a rough, spattery bead.

6013: A popular all-purpose stick electrode for carbon and galvanized steel and the first choice for light gauge sheet metal. Has low penetration and a more aesthetic bead when compared to 6010

7018: An AC/DC low hydrogen rod used to weld high strength joins heavy sheets and plates. Not for dirty metal. The bead itself will be smooth, clean, and free of spatter.

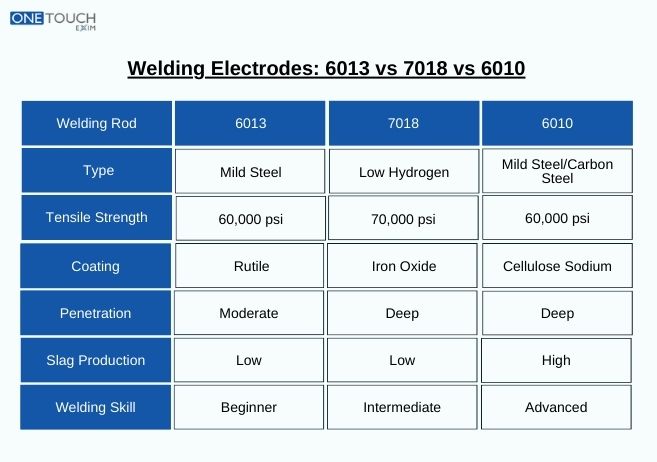

Comparison Between 6013 vs 7018 vs 6010

| Welding Rod | 6013 | 7018 | 6010 |

| Type | Mild Steel | Low Hydrogen | Mild Steel/Carbon Steel |

| Tensile Strength | 60,000 psi | 70,000 psi | 60,000 psi |

| Position | All Positions | Flat, Horizontal, Vertical | All Positions |

| Coating | Rutile | Iron Oxide | Cellulose Sodium |

| Penetration | Moderate | Deep | Deep |

| Slag Production | Low | Low | High |

| Welding Skill | Beginner | Intermediate | Advanced |

| Applications | General purpose welding | Structural welding, heavy-duty welding | Pipe welding, high-speed welding |

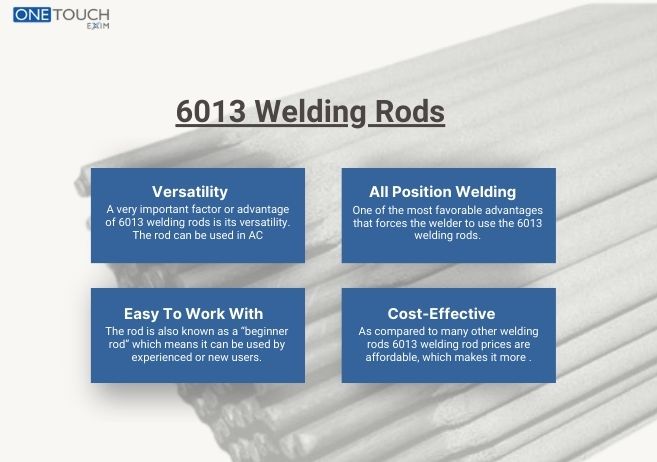

6013 Welding Rod:

The 6013 is an all purpose AC/DC electrode for general shop and field use such as lightly painted or rusty plated of mill scale. It exhibits a soft penetration profile that is forgiving on thin, clean or poorly fitting materials. It has a fast-freezing slag that reduces spatter and an easily removed slag. It isn’t quite as strong as 7018, but great for sheet metal, fabricating and quick repairs, especially when appearance and ease are more important than tensile strength.

Advantages of 6013 Welding Rod:

- Easy to Use : Perfect for a new one with a stable, easy to control arc and virtually no spatter.

- Work Well on All Size Machine : Handle on Ac or Dc Welding machine.

- Smooth Beads : Exquisite welds, easy for slag remove.

- Forgiving : Accepts less than perfectly clean metal and fits gaps nicely

- Thin Metal Master : Perfect for sheet metal or thin-gauge steel because of its low penetration.

Disadvantages of 6013 Welding Rod:

- Less Strength : Makes less strong welds with less tensile strength as similar to rods such as the 7018 so not suitable for critical load bearing fabricated weld joints.

- Poor Penetration Coverage : Arc is soft and does not penetrate well enough, resulting in poor fusion on thicker materials or in poor fit up joints

- Slag Inclusion : The liquid slag can cause issue for new ones and tend to be stuck in the weld if not cleaned correctly between when multiple passes are used.

- Not for Dry Metal – Somewhat tolerant, but not nearly as much as a 6010 electrode on rusty, painted or dirty metal.

7018 Welding Rod:

7018 is a low-hydrogen, iron powder electrode that produces high quality, dense weld deposits which are high in strength and low in life ductility. It works well on both AC and DC and it’s a great choice for welding mild and low alloy steel, general and structural steels and even some high stress steels. It has a stable arc that generates lower spatter and easy slag removal. The 7018 has to be stored in a holding oven to maintain a sealed environment, otherwise moisture is absorbed and will create HIC’s in the weld.

Advantages of 7018 Welding Rod:

- Excellent Strength : Delivers high tensile strength, very strong welds with excellent impact strength at low temperatures.

- High Finish : Excellent, high wetting, smooth and clean beads with very little spatter and less smog, with easy removal slag.

- Low Hydrogen : This coating makes the product low-hydrogen and therefore reduces the risk of hydrogen-induced cracking in a weld.

- Good Penetration & Fusibility : The rod provides good penetration and fusibility for creating strong, top-quality welds on thicker steel or steel threading and coupling applications.

- Dual Current : Works equally well in AC or DC welding machines.

Disadvantages of 7018 Welding Rod:

- Strenuous Storage : It has to be stored in a vacuum oven to avoid moisture contamination and hydro generation.

- Dirty Metal : Very poor on rusty, painted or oily surface, all of which must be totally clean (base metal cannot show any rust, paint or moisture).

- Hard Arc Start : Tends to strike and hold a steady arc, particularly not good for novice.

- Not as good in confined positions : Although Versatile, if you are welding in confined positions, you might find this rod’s fluid puddle hard to manage, particularly when welding in overhead and vertical-up positions, which is where other electrodes excel at.

6010 Welding Rod:

The 6010 is a fast freeze, cellulose sodium, all position electrode which may only be used DC+ currents. It’s very good at penetrating to depth and would be the superior choice for welding dirty, rusty or rusty steel or unpainted steel, especially in pipe welding. This creates an arc that penetrates contaminants which make it ideal for out-of-position welding (vertical and overhead). The weld bead: usually not very smooth, more like bumpy and spattery with a very thin slag that is hard to break.

Advantages of 6010 Welding Rod:

- Deep 60 Degree Digging Angle : It has an unparalleled digging arc in the welding industry for digging straight down with depth penetration to weld through paint, rust and dirt.

- Slag Clean-up : Fast Freezing Slag is used for out-of-position welding.

- Pushes Contaminates Out : Ideal for Condition materials when you cannot clean it properly.

- Visual Examinations : Visibility of weld pool and ability to detect defects is due to thin slag and clear bead profile.

- Root Passes – This is for open root pipe welds, because it gets deep and come back nice.

Disadvantages of 6010 Welding Rod:

- DC only for use on a DC welding machine : Not suitable for AC welding note; Not suitable for common AC arc welder.

- Demanding Applications : Very skill-intensive in order to manage its aggressive, deep digging arc and then minimizing burn through.

- Rough Finish : Coarse, spattery bead appearance which may require significant time for cleaning.

- Tough Slag : The thin slag has poor self-lift slag removal.

- Not recommended for clean/Thin Metal : It cuts extremely aggressively and not recommended for thin metal or the final pass on a workpiece.

Conclusion:

Select the rod by task for deep penetration on dirty steel and pipe. 7018 for strong, high quality welds made on clean metal.6013 for easy drag on thin, sheet metal type metals and low amp welding settings/applications on plate metals and middle alloy steels and both serve a unique role in the welders. Experimenting with each type and gaining practical experience is key to mastering the art of welding with these Rod.