In under thirty years lithium-ion batteries have changed dramatically from being used to power little gadgets to powering massive applications like stationary energy storage systems and electric vehicles. The use of graphite-based anodes in place of soft and hard carbons has been a significant development in this journey. The low lithiation potential of graphite and its remarkable (theoretical) gravimetric capacity of 372 mAh/g have contributed to this change, which has greatly increased full-cell energy densities. This blog post will discuss graphite welding rods, which are an excellent option for beginners as they can be utilized for a wide range of welding applications.

What Are Graphite Rods?

Thin straight rods made of ceramic, metal, plastic or organic material are called rods. Depending on their size and composition they can perform a multitude of tasks and are reasonably easy to build. Graphite rods are a particular kind of rod made from machined graphite or graphite compounds. Since graphite is a non-fatiguing material, they are well recognized for its outstanding heat resistance, good corrosion resistance, strong thermal shock resistance, non-reactivity, and ability to age well. Because of its strength and durability, graphite has surpassed ordinary steel and other carbon mixes to become one of the most widely used industrial materials in factories and other heavy machinery. Find the perfect match for your welding needs with our variety of ranges. Buy a graphite welding rod at OneTouch Exim & explore our collection today.

Is Graphite Man Made Or Natural?

Graphite can be produced artificially or found naturally. Mining for naturally occurring graphite resources occurs in several nations, including China, Madagascar, Brazil and Canada. These deposits are created by a mixture of igneous and metamorphic physical processes. Heating a range of carbon containing materials such as coal, pitch, acetylene or petrochemicals, produces synthetic graphite. Graphite is created when carbon atoms are superheated, or heated to temperatures greater than 4000°C. It is acknowledged that synthetic graphite is purer than graphite which occurs naturally.

What Is The Future Of Graphite Electrodes?

It is projected that the global market for graphite electrodes will grow significantly between 2023 and 2030. The market is likely to expand beyond the estimated horizon in 2022 due to the constant growth rate and increasing adoption of tactic by major players. Steel manufacturing in electric arc furnaces is the primary application for graphite electrodes. As of right now these are the only items that can withstand the intense heat produced in this demanding environment while also having high levels of electrical conductivity.

What Are The Advantages And Disadvantages Of Graphite?

Following are some of the advantages & disadvantages of graphite welding rods:

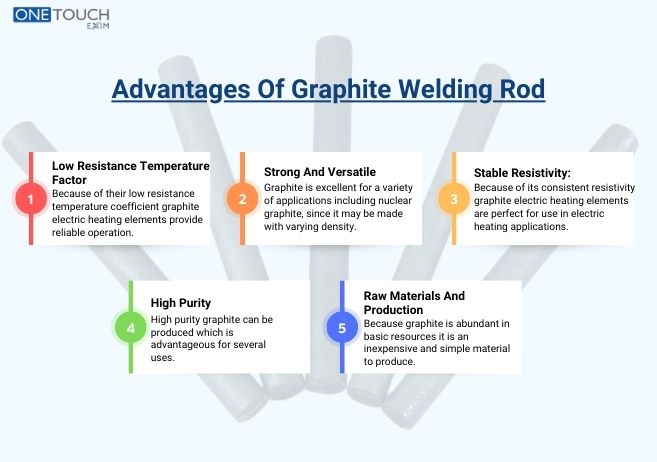

Graphite Has Several Benefits Including:

- Low resistance temperature factor: Because of their low resistance temperature coefficient graphite electric heating elements provide reliable operation.

- Strong and versatile: Graphite is excellent for a variety of applications including nuclear graphite, since it may be made with varying density requirements.

- Stable resistivity: Because of its consistent resistivity graphite electric heating elements are perfect for use in electric heating applications.

- High purity: High purity graphite can be produced which is advantageous for several uses.

- Raw materials and production: Because graphite is abundant in basic resources it is an inexpensive and simple material to produce.

The Following Are Some Of Graphite’s Drawbacks:

- Reactivity with specific materials: In some applications extra care needs to be taken to ensure that the support and connection do not respond with graphite.

- Anisotropic crystal form: Graphite’s characteristics vary depending on the direction they are oriented in due to its anisotropic crystal structure.

- Volatility in a vacuum atmosphere: In vacuum graphite can volatilize and produce a carbon environment that might be unsuitable for treating some materials.

- Infirmity at room temperature: Because of its relative softness at ambient temperature graphite is easily broken and damaged.

What Are Graphite Welding Rods Used For?

Cast iron is the main material that graphite welding rods are used for. Because of its high carbon content which makes it brittle and challenging to work with cast iron is a material that is famously tough to weld. This issue can be resolved with graphite welding rods commonly referred to as graphite electrodes.

The graphite rod serves as a filler material and an electrode when used in welding. The surrounding cast iron is partially melted by the extreme heat produced by the graphite electrode the molten metal is reinforced and the cooling process is regulated by the graphite filler material reducing the likelihood of cracking. All things considered graphite welding rods are a useful tool in sectors like construction, manufacturing and automotive where cast iron components are frequently used by welders to join pieces of iron together.

Conclusion

Graphite is an excellent material for lithium-ion intercalation because of its distinct layered structure. Graphite anodes have considerable first cycle capacity loss despite having outstanding conductivity and stability because of uncontrollably forming the solid electrolyte interface and unwanted electrolyte breakdown processes. The advancement of graphite-based anodes in batteries depends on striking a balance between cost and complexity and enhancing the battery’s stability, efficiency, and capacity. Although coal tar pitch is the conventional industrial coating for graphitic anodes, there are serious health and environmental issues with it.