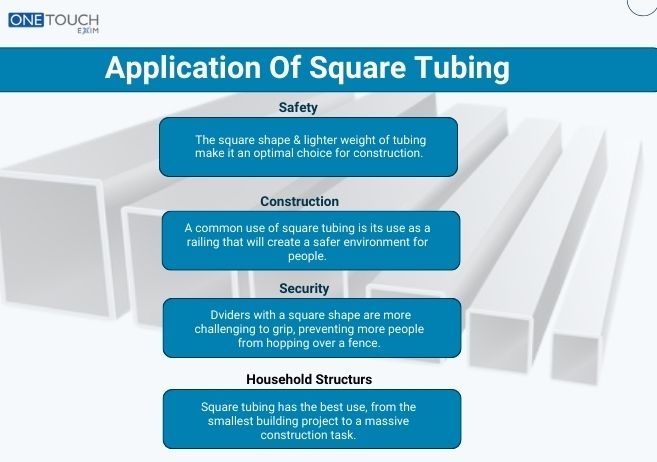

The square tubular design of these chaises maximize strength-to-weight and torsional rigidity. Its flat sides make it easy to work with, ready for welding, drilling and connecting consistent touch points. It can also be used as a frame, support or a protective cage in various other applications including construction, transportation and furniture. The hollow portion also is useful to hide wiring or plumbing. It’s sleek, with beer guards and handrails. Whether for industrial or DIY use, square tubing is an essential building material.

Strongest Steel Tubing

The toughest steel tubes are usually DOM (Drawn Over Mandrel) mechanical tubing produced from high strength low alloy (HSLA) steels or alloys such as 4130 chromoly. The cold-drawing process hardens the steel, which produces a seamless like appearance and offers better dimensional sectional precision than other similar material with high tensile strength, fatigue and impact resistance. For maximum strength in demanding applications such as roll cages, hydraulic cylinders and structural components, heat-treated 4130 tubing is the benchmark. The strength is not only in the material, but the process of order that occurs where the grain structure has been controlled.

What Is Square Tubing?

Square Tubing section also known as Steel Box Section, is a type of structural tubular or hollow sanction with a square cross section. It is manufactured through a technique that involves taking flat sheet metal, commonly steel or aluminium, and forming it into a tubular shape while the edges of the metal are welded together to form the seam. The welded up cylinder is then travelled through a succession of dies, forming the mat into a square. This results in a product with 4 equal sides and a 90 degree angle.

What makes it stand out is its geometric shape that offers great strength and rigidity. The material is distributed farther from the central axis, with the result having a high moment of inertia apparent in figure. This makes it very resistant to bending and crucially much more resistant than almost any other shape to torsional forces in general.

With a variety of physical shapes and sizes, it allows each steel to serve even more specialized applications than on the regular round tubing. Its box-shape design allows for much greater strength and rigidity compared to angles or channels. This disproportionate balance of strength to weight, torsional resistance and easy maintenance is what make it a vital contender for building frames, racks, gates or load-bearing trusses in construction design at your facility.

How Strong Is Square Tubing?

Square tubing provides the necessary strength with its effective geometry. The helical “wound” design adds incredible strength, and the square shape offers excellent torsional twisting and bending resistance (although slightly less from side to side than a similar weight of flat bar or angle iron). The amount of strength a hollow tube has is based on the material it’s made from (steel and aluminium often). How thick its walls are and what shape it is. The same amount of material distributed uniformly away from the central axis produces a high moment of inertia beam that will carry heavy loads with little deflection. This high strength material exhibits an excellent combination of strength and structural stability, which is good for frames and load bearing supports.

Advantages of Stainless Steel Tubing

The stainless steel tubing’s light weight is convenient when you need to transport it. And its strong resistance to corrosion can stand up to harsh environments. It eliminates the necessity for protective coatings and for the long terms, reduces maintenance. It also boasts a superior strength-to-weight ratio. Virtually unmatched durability and a sleek clean look that is easy to keep sanitized. Besides, it is more stable at both high and low temperatures than most other substances. These characteristics make it an ideal, durable choice for many tough applications in construction equipment, automobiles, medical equipment and food processing plants everywhere cleanliness, stability and high stiffness are needed.

When Should We Use Square Tubing?

Use Square Tubing if requiring high torsional stiffness and redundant axes strength. It is easy to join with welding, brazing and soldering. This material has a coated surface for improved backside absorption, not suitable for a cosmetic anodizing quality. Its flat smooth finish makes it ideal for frames, structures, ramps, machinery equipment and 46K used placement and incensement projects. It is stronger than round tubing and is less likely to become deformed due to all of the loads that can occur in load-bearing applications. The geometric shape brings a contemporary, clean look to architectural features and furniture as well. Select a blank square when you need an economical, rigid and easily machinable leading lightweight structural system for both industrial and ornamental applications.

Conclusion

Square tubing is a superior product for structural applications compared to other structural products such as pipe, with its flat surfaces and smooth edges it is for rigid frameworks, bridges, supports and architectural structures in which strength along the length of bars are used.