Incoloy 800 was formerly known as Inconel 800 when they were essentially the same alloy, currently known as INCOLOY alloy 800. This was a misnomer called “Inconel”. This nickel-iron-chromium alloy was developed specifically to provide high-temperature corrosion protection. Alloy 800’s main characteristics are that it can withstand extreme power while still resisting oxidation at temperatures up to about 1300 degree fahrenheit and relatively good carburization and sulfidation immunity. This is not a common INCONEL type high strength alloy. The difference is that modern versions have distinct distinctions; Incoloy 800H and Incoloy 800HT, which are improved with a higher carbon content. Other alloys such as INCONEL 600 or 625. Include higher nickel content and are therefore more resistant to corrosion in more severe scenarios.

Difference b/w Incoloy 800 vs Inconel 800

It’s important to note that “Inconel 800” is a misnomer and never used as standard terminology. The proper name for this nickel-iron-chromium alloy is INCOLOY 800.

The confusion arises from the fact that incoloy and inconel are two trademarked families of high performance alloys made by the same company. The salient difference between the families is that inconel alloys are not usually precipitation hardened, this being associated with the fabrication of components while in the case of Incoloy it is a treatment by relatively low temperature heating.

There is no difference between “Incoloy 800” and the misnomer “Inconel 800”, and no difference in strength or resistance to high temperature/oxidation. The contemporary, standardized grades are Incoloy 800H and 800HT, the former of which is modified to only have a restricted carbon content for increased creep-rupture strength at their highest applications temperatures.

Features of the Incoloy 800

Incoloy 800 is a Nickel-Iron-Chromium superalloy that offers potential resistance to high temperature oxidation and carburization. It was further modified into alloy 800H by lowering carbon content to 0.05 – 0.10% which is further modified to 800HT to control titanium and aluminium contents for improved high temperature performance. One of its most important characteristics is that it contains approx 32% nickel and 21% chromium as well as an addition of titanium, which stabilizes performance at high temperatures while giving a dual advantage to the material when in oxidizing or reducing atmosphere.

This alloy also provides good resistance to stress corrosion cracking involving sulfides and chlorides. It has good mechanical properties over a wide range of temperature, and holds good bending strength not only at room temp but as well as under high temperatures. Typical applications are heat treatment equipment, industrial furnaces, nuclear reactors and other components that require resistance to thermal shock and corrosion. The fact that it can handle cyclic heating and cooling without a significant loss in performance boosts the reliability of tribology-relevant industrial uses even more.

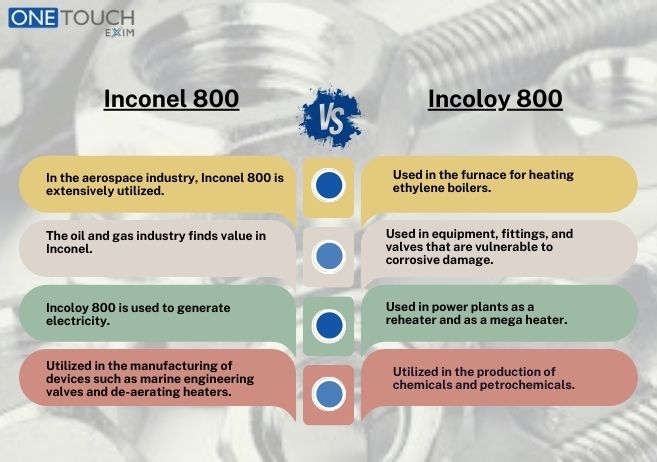

Uses of Inconel 800 and Incoloy 800 alloy

Although there were no materials standard for alloys such as “Inconel 800” the authentic one and other incoloy 800 types (H/HT) had been utilized extensively owing to their outstanding strength at high temperature condition and corrosion resistance.

Primary applications include:

- Heat Treating : Resistant to oxidation and carburization in the high temperatures operation.

- Chemical Process Equipment : Being resistant to most chemicals and having a large temperature resistance makes alloys and s31277 an ideal material in chemical processing.

- Power Generation : As tubing for superheaters and reheaters in fossil fuel power plants, including nuclear reactor core components.

- Petrochemical : Catalyst supports grids, transfer piping and more in high temperature requirements.

It is its stability under thermal cycling and resistance to a range of corrosive gases that makes it vitally important in these demanding industries where long life and reliability are essential.

Price structure of Inconel 800 and Incoloy 800

The cost of Incoloy 800 (Alloy 800) can be variable and tends to involve multiple variables. The major driving force is the cost of its constituent metals, nickel, chromium and iron – particularly high nickel pricings.

Shipping costs are also calculated based on product shape (bar, plate or tube), dimensions and order size. Mill premiums, complex manufacturing (e.g. for seamless tubes) and supplier markups impact the final price as well. Normally, material in speciality shapes (such as thin-walled tubing) will bear a much higher cost per kilogram than standard bar stock.

Use of Inconel 800 alloy in Aerospace/Automotive

The term is a misnomer, Incoloy 800H does have some applications in industry mostly due to lack of Aluminized or chromed predecessor. Uselts predominant use is high strength oxidation and carburization at elevated temperatures.

In aerospace, it’s employed in particular engine parts, exhausts systems and heat-treating fixtures that run at continually high temperatures but not quite the extreme loads supported by stronger alloys like inconel 718.

In automotive, you’ll find it relegated to race-only or high-performance exhaust manifolds and turbocharger housings, as well as other parts demanding thermal stability.

Conclusion

In the end, Inconel 800 is an incorrect, but historical name for what should be called incoloy 800. It is the same, with no substantive difference. That difference is solely in the letter of the metal name, which indicates it to be a member of the nickel-iron-chromium Incoloy family rather than of the nickel-chromium Inconel line. Ultimately, “Inconel 800” is an improper historical reference to the alloy by its name, Incoloy 800. They are one and the same. The difference is at the most generic level, that a nickel-iron-chrommium alloy is an incoloy, not an Inconel.